4130 Alloy Steel Pipe e se nang Seamless

Tlhaloso e Khutšoanyane:

4130 Alloy Steel Pipe:

4130 alloy steel pipe ke tšepe e tlaase e nang le chromium le molybdenum e le lisebelisoa tse matlafatsang. E fana ka tekanyo e ntle ea matla, ho tiea, le ho cheseha, ho e etsa e loketseng lits'ebetso tse hlokang matla a holimo le nako e telele, joalo ka indastering ea sefofane, likoloi, le oli le khase. Alloy e boetse e tsejoa ka ho hanyetsa mokhathala o matla haholo 'me e sebelisoa hangata ho likarolo tsa meralo joalo ka liforeimi, shafts le liphaephe. Ntle le moo, tšepe ea 4130 e ka tšeloa mocheso ho ntlafatsa thepa ea eona ea mochini, ho ntlafatsa ts'ebetso ea eona maemong a boima.

Litlhaloso tsa 4130 Steel Seamless Tube:

| Litlhaloso | ASTM A519 |

| Kereiti | 4130 |

| Kemiso | SCH20, SCH30, SCH40, XS, STD, SCH80, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Mofuta | Seamless |

| Sebopeho | Rectangular, Round, Square, Hydraulic Etc |

| Bolelele | 5.8M,6M & Bolelele bo Hlokehang |

| QETA | Qetello e Beveled, Qetello e Setlehileng, E hatakeloa |

| Setifikeiti sa Tlhahlobo ea Mill | EN 10204 3.1 kapa EN 10204 3.2 |

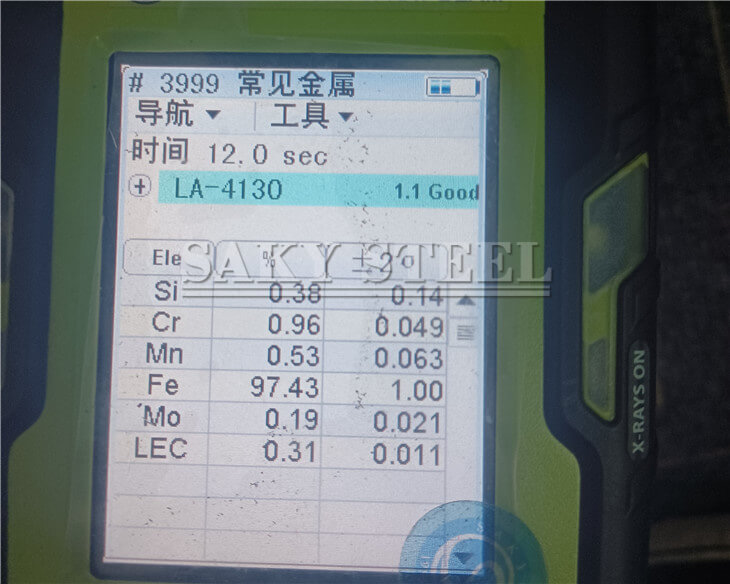

AISI 4130 Pipes Sebopeho sa Lik'hemik'hale:

| Kereiti | C | Si | Mn | S | P | Cr | Ni | Mo |

| 4130 | 0.28-0.33 | 0.15-0,35 | 0.4-0.6 | 0.025 | 0.035 | 0.08-1.10 | 0.50 | 0.15-0,25 |

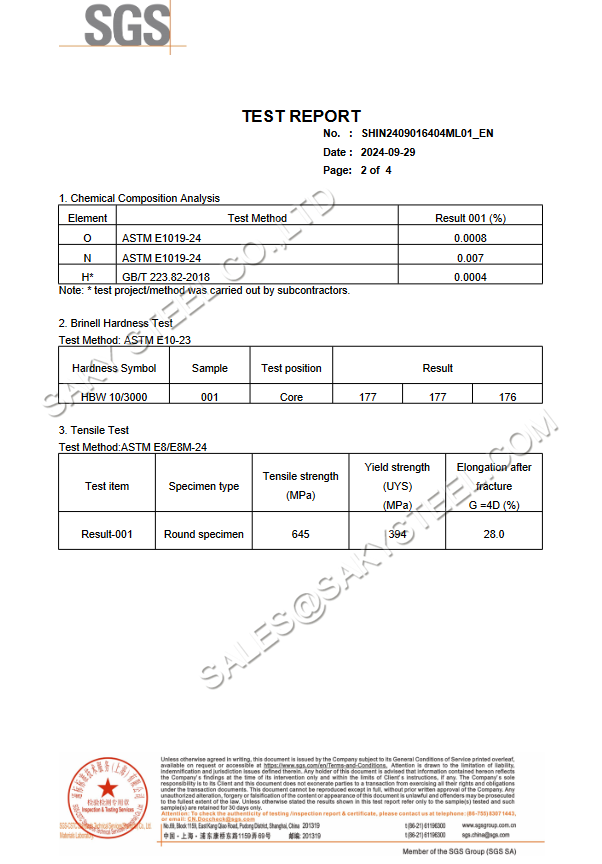

Mechanical Properties ea 4130 Round Pipes:

| Kereiti | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Matla a Kotulo 0.2% Bopaki (MPa) min |

| 4130 | MPa - 560 | 20 | MPa - 460 |

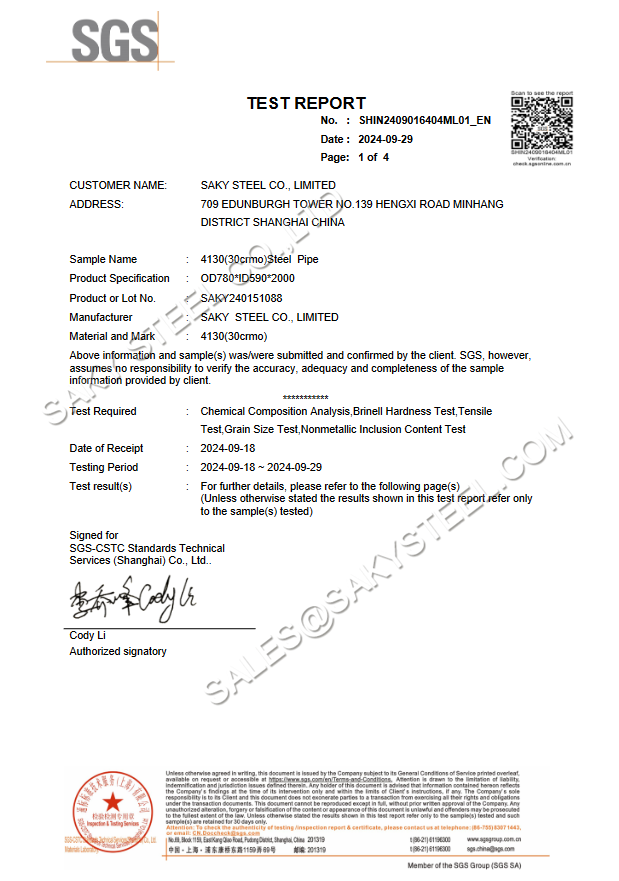

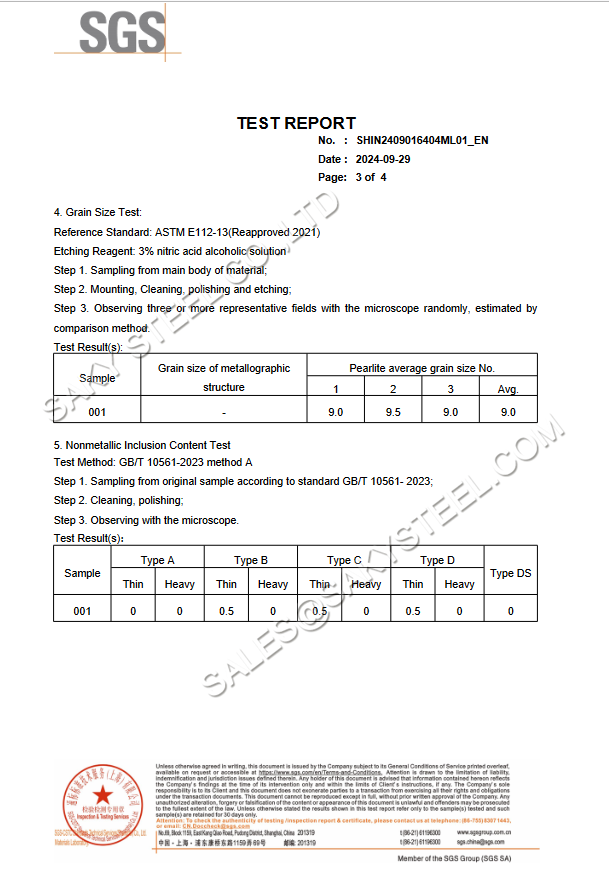

UNS G41300 Steel Round Tube Teko:

Setifikeiti sa 4130 Alloy Steel Round Tube:

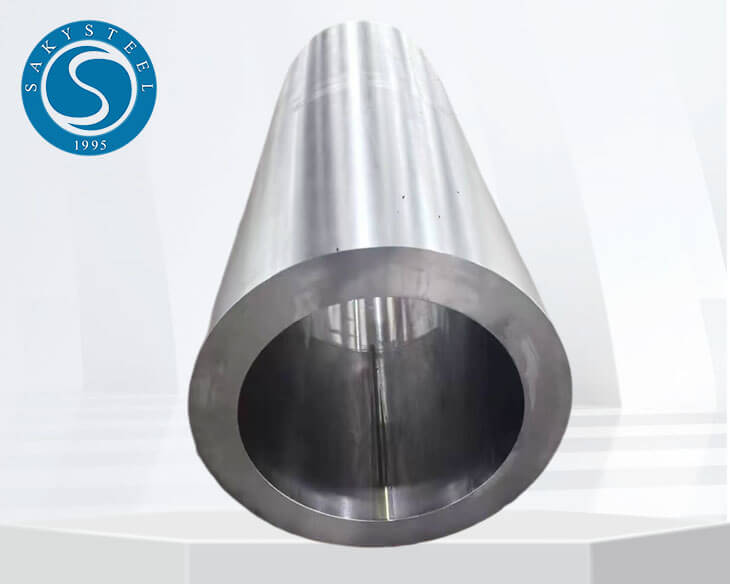

UNS G41300 Steel Round Tube Rough Turning:

Phetoho e mahlahahlaha ke ts'ebetso ea pele ea mochini e sebelisetsoang ho tlosa lisebelisoa tse ngata ho phala ea 4130 alloy steel seamless. Ts'ebetso ena e bohlokoa bakeng sa ho etsa hore mosebetsi o be boemong bo haufi le ho qetela pele o qeta ts'ebetso. 4130 alloy steel, e tsejoang ka matla a eona, ho tiea, le machinability e ntle, e arabela hantle ts'ebetsong ena, e lumella ho tlosoa ha thepa ka katleho. Nakong ea ho phethoha ka thata, mochine oa lathe kapa oa CNC o sebelisoa ho potlakisa ho fokotsa bophara ba phala, ho e lokisetsa bakeng sa ho fetola ka mokhoa o nepahetseng kapa mesebetsi e meng ea bobeli. Khetho e nepahetseng ea lisebelisoa le ho pholisa li bohlokoa ho laola mocheso le ho netefatsa boleng bo holimo le bophelo ba lisebelisoa.

Melemo ea 4130 Alloy Steel Seamless Pipe:

1.High Strength-to-Weight Ratio: 4130 alloy steel e fana ka matla a babatsehang ha e ntse e boloka boima bo batlang bo le tlase, e etsa hore e be se loketseng bakeng sa likopo tse hlokang ho tšoarella le ho fokotsa boima ba thepa, joalo ka indasteri ea lifofane le ea likoloi.

2.Good Weldability: Ho sa tsotellehe matla a eona a phahameng, 4130 alloy steel e tsejoa ka ho cheseha ha eona. E ka chesetsoa ka mekhoa e fapaneng (TIG, MIG) ntle le tlhokahalo ea ho futhumatsa ho hoholo, ho etsa hore e feto-fetohe bakeng sa ho etsoa ha moralo.

3.Toughness and Fatigue Resistance: Alloy e fana ka boima bo phahameng le ho hanyetsa mokhathala o phahameng, ho etsa hore e tšoanelehe bakeng sa lits'ebetso tse hlokahalang tse kang li-tubing tse nang le khatello e phahameng le likarolo tsa mechine tse tlas'a khatello ea kelello.

4. Corrosion Resistance: Le hoja e se e thibelang kutu joaloka tšepe e sa hloekang, 4130 alloy steel e sebetsa hantle libakeng tse bonolo ha e koahetsoe kapa e phekoloa hantle, e lelefatsa bophelo ba eona maemong a thata.

5.Good Machinability: 4130 alloy steel e batla e le bonolo ho mochine ha e bapisoa le litšepe tse ling tse matla haholo, e leng se etsang hore e be le litšenyehelo tse ngata mekhoeng ea ho etsa thepa, ho akarelletsa le ho fetola, ho sila le ho phunya.

6. Likopo tse fapaneng: Mohaho o se nang moeli le matla a phahameng a etsa hore pipe ea tšepe ea 4130 alloy alloy e be e loketseng bakeng sa lisebelisoa tsa bohlokoa tse kang li-hydraulic tubing, ho cheka oli le khase, meralo ea meralo, le likarolo tsa sefofane.

Ke Hobane'ng ha U Re Khetha?

1.Ka boiphihlelo ba lilemo tse fetang 20, sehlopha sa rona sa litsebi se netefatsa boleng ba boleng bo holimo morerong o mong le o mong.

2.Re khomarela mekhoa e thata ea ho laola boleng ho netefatsa hore sehlahisoa se seng le se seng se finyella litekanyetso.

3.Re sebelisa theknoloji ea morao-rao le litharollo tse ncha ho fana ka lihlahisoa tse phahameng.

4.Re fana ka litheko tsa tlhōlisano ntle le ho sekisetsa boleng, ho netefatsa hore u fumana boleng bo botle ka ho fetisisa bakeng sa letsete la hau.

5.Re fana ka mefuta e fapaneng ea lits'ebeletso ho fihlela litlhoko tsohle tsa hau, ho tloha lipuisanong tsa pele ho isa phepelong ea ho qetela.

6.Boitlamo ba rona ho ts'ebetsong le mekhoa ea boitšoaro bo tiisa hore mekhoa ea rona e boloka tikoloho.

Tšebeletso ea rona:

1. Ho khutsisa le ho khutsisa

2.Ho phekola mocheso oa vacuum

3.Bokaholimo bo pentiloeng ka seipone

4.Precision-milled finish

4.CNC mechine

5.Ho cheka ka mokhoa o nepahetseng

6.Khaola likarolo tse nyane

7.Fihlella ho nepahala ha hlobo

Sephutheloana sa Pipe ea Matla a Phahameng:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,