4130 Ingxubevange yentsimbi yombhobho ongenamthungo

Inkcazelo emfutshane:

4130 ingxubevange yombhobho wentsimbi:

I-4130 i-alloy iron pipe yintsimbi ye-alloy ephantsi equkethe i-chromium kunye ne-molybdenum njengama-agent aqinisayo. Inika ibhalansi elungileyo yamandla, ukuqina, kunye nokuwelda, iyenza ilungele usetyenziso olufuna ukomelela okuphezulu kunye nokuqina, njengakwi-aerospace, iimoto, kunye ne-oyile kunye nemizi-mveliso yerhasi. I-alloy ikwaziwa ngokumelana nokudinwa okugqwesileyo kwaye iqhele ukusetyenziswa kumacandelo olwakhiwo olufana neefreyimu, iishafu, kunye nemibhobho. Ukongeza, intsimbi ye-4130 inokunyangwa ubushushu ukuze iphucule iipropathi zayo zoomatshini, iphucule ngakumbi ukusebenza kwayo kwiindawo ezifunwayo.

Iinkcukacha ze-4130 Steel Seamless Tube:

| Iinkcukacha | I-ASTM A519 |

| IBanga | 4130 |

| Ishedyuli | SCH20, SCH30, SCH40, XS, STD, SCH80, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Uhlobo | Ayinamthungo |

| Ifom | Uxande, Round, Square, Hydraulic Etc |

| Ubude | 5.8M, 6M kunye noBubude obufunekayo |

| Isiphelo | Isiphelo esiBeveled, isiphelo esicacileyo, sinyathelwe |

| Mill Test Certificate | EN 10204 3.1 okanye EN 10204 3.2 |

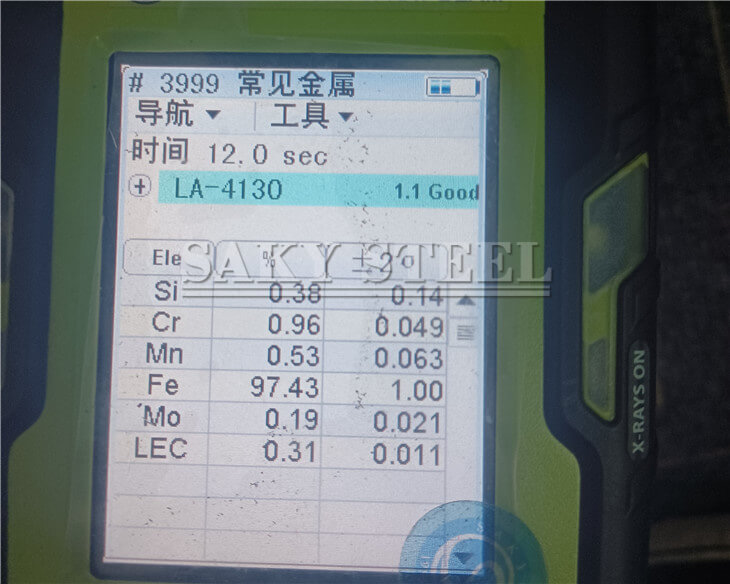

I-AISI 4130 iMibhobho yoBume beMichiza:

| IBanga | C | Si | Mn | S | P | Cr | Ni | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | 0.025 | 0.035 | 0.08-1.10 | 0.50 | 0.15-0.25 |

IiPropati zoomatshini beMibhobho eRound 4130:

| IBanga | Amandla e-Tensile (MPa) min | Ubude (% kwi-50mm) min | Amandla eSivuno 0.2% Ubungqina (MPa) min |

| 4130 | MPa – 560 | 20 | MPa – 460 |

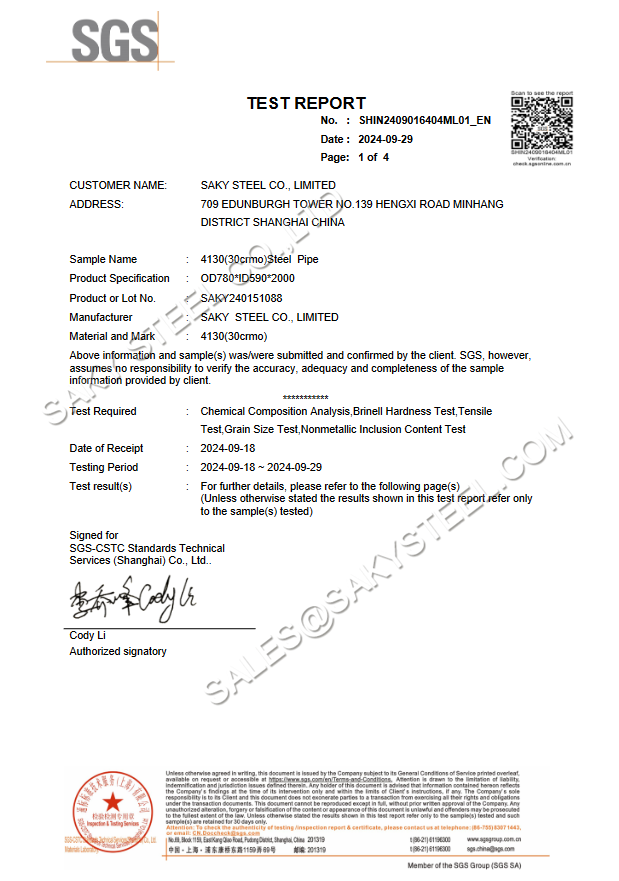

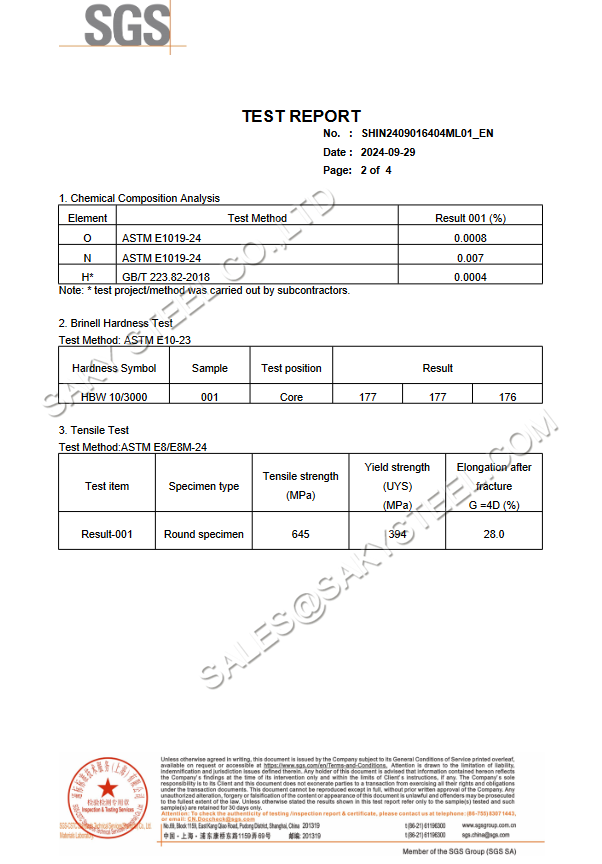

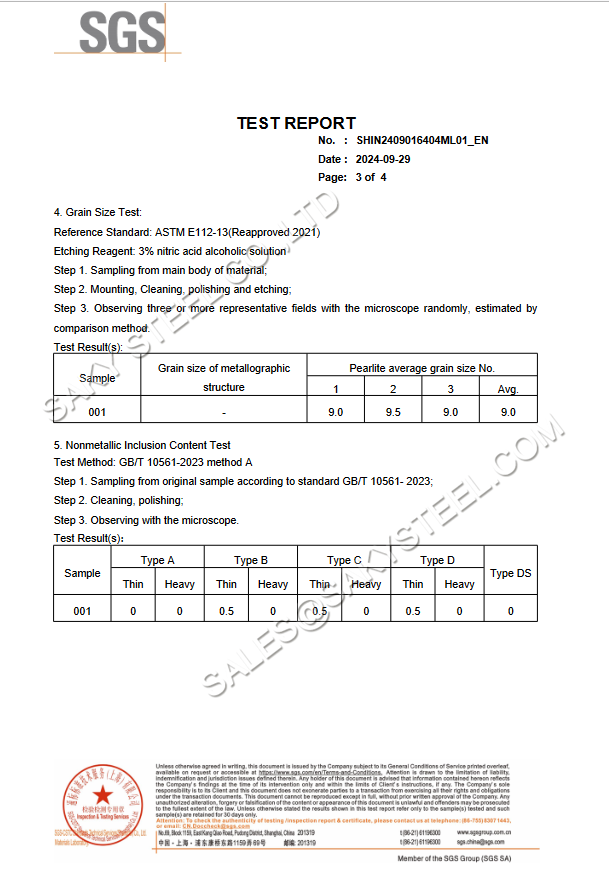

Uvavanyo lwe-UNS G41300 yentsimbi eRound Tube:

Isatifikethi se-4130 se-Alloy Steel Round Round Tube:

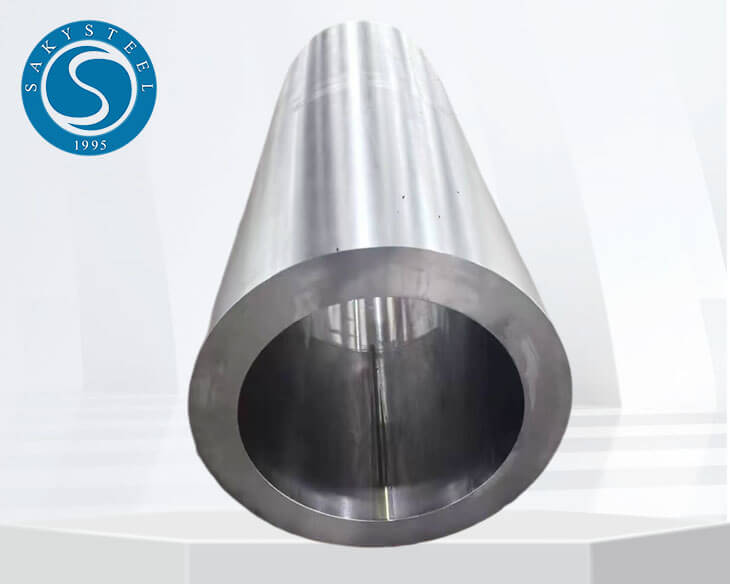

I-UNS G41300 yeSteel Round tube Round Turning:

Ukujika okurhabaxa yinkqubo yokuqala yomatshini esetyenziselwa ukususa izinto ezininzi kumbhobho we-4130 wentsimbi engenamthungo. Le nkqubo ibalulekile ekubumbeni i-workpiece ibe yifom ekufutshane neyokugqibela phambi kokugqiba imisebenzi. I-4130 insimbi ye-alloy, eyaziwayo ngamandla ayo, ukuqina, kunye nokusebenza kakuhle, iphendula kakuhle kule nkqubo, ivumela ukususwa kwezinto ezifanelekileyo. Ngethuba lokujika ngokukhawuleza, i-lathe okanye umatshini we-CNC usetyenziselwa ukusika ngokukhawuleza ububanzi bombhobho, ukuwulungiselela ukujika ngokuchanekileyo okanye eminye imisebenzi yesibini. Ukukhethwa kwesixhobo esifanelekileyo kunye nokupholisa kubalulekile ukulawula ubushushu kunye nokuqinisekisa umgangatho ophezulu wendawo kunye nobomi besixhobo.

Izibonelelo ze-4130 Alloy Steel Pipe engenamthungo:

I-1.I-High Strength-to-Weight Ratio: I-4130 yentsimbi ye-alloy inika amandla abalaseleyo ngelixa igcina ubunzima obuncinci, iyenza ilungele izicelo ezifuna ukuqina kunye nokunciphisa ubunzima bezinto eziphathekayo, ezifana ne-aerospace kunye nemizi-mveliso yeemoto.

I-2.Good Weldability: Nangona amandla ayo aphezulu, i-4130 intsimbi ye-alloy iyaziwa ngokuba yi-weldability yayo. Inokuthi idityaniswe kusetyenziswa iindlela ezahlukeneyo (TIG, MIG) ngaphandle kwesidingo sokufudumeza okubanzi, okwenza kube yinto eguquguqukayo yokwenziwa kwesakhiwo.

I-3.Ukuqina kunye nokumelana nokukhathala: I-alloy inika ubunzima obuphezulu kunye nokumelana nokudinwa okuphezulu, okwenza ukuba ifanelekele izicelo ezifunwayo ezifana ne-high-pressure tubing kunye namacandelo omatshini aphantsi koxinzelelo.

I-4.I-Corrosion Resistance: Nangona ingekho njenge-corrosion-resistant njengensimbi engenasici, i-4130 alloy steel iqhuba kakuhle kwindawo epholileyo xa igqunywe ngokufanelekileyo okanye iphathwa, yandisa ubomi bayo kwiimeko ezinzima.

I-5.Good Machinability: I-4130 yensimbi ye-alloy ilula kakhulu kumatshini xa kuthelekiswa nezinye iintsimbi eziphezulu, okwenza kube yindleko-mali kwiinkqubo zokuvelisa, kuquka ukujika, ukugaya kunye nokugaya.

I-6.Izicelo eziNqabileyo: Ukwakhiwa okungenamthungo kunye namandla aphezulu kwenza i-4130 i-alloy iron pipe ilungele izicelo ezibalulekileyo ezifana ne-tubing ye-hydraulic, i-oyile kunye ne-gas drilling, i-structural frameworks, kunye ne-aerospace components.

Kutheni Khetha Thina?

I-1.Ngeminyaka engama-20 yamava, iqela lethu leengcali liqinisekisa umgangatho ophezulu kwiprojekthi nganye.

2.Sinamathela kwiinkqubo ezingqongqo zokulawula umgangatho ukuqinisekisa ukuba yonke imveliso ihlangabezana nemigangatho.

3.Sisebenzisa itekhnoloji yamva nje kunye nezisombululo ezintsha zokuhambisa iimveliso eziphezulu.

4.Sinikezela ngamaxabiso akhuphisanayo ngaphandle kokuthomalalisa umgangatho, ukuqinisekisa ukuba ufumana elona xabiso lilungileyo kutyalo-mali lwakho.

5.Sinikezela ngoluhlu olubanzi lweenkonzo ukuhlangabezana nazo zonke iimfuno zakho, ukusuka ekudibaneni kokuqala ukuya kunikezelo lokugqibela.

6.Ukuzinikela kwethu ekuzinzeni nasekuziphatheni okusesikweni kuqinisekisa ukuba iinkqubo zethu zihambelana nokusingqongileyo.

Inkonzo yethu:

1. Ukucima kunye nokufudumala

2.Ukunyanga ubushushu bevacuum

3.Isipili esimenyezeliswe phezulu

4.Precision-milled finish

4.CNC machining

5. Precision ukomba

6.Sika ube ngamacandelo amancinci

7.Ukuphumelela ukuchaneka okufana nokungunda

Ukupakishwa kombhobho we-alloy wamandla aphezulu:

1. Ukupakisha kubaluleke kakhulu ngokukodwa kwimeko yokuthunyelwa kwamanye amazwe apho umthwalo udlula kwiitshaneli ezahlukeneyo ukuya kufika kwindawo yokugqibela, ngoko ke sibeka inkxalabo ekhethekileyo malunga nokupakishwa.

2. I-Saky Steel's ipakisha iimpahla zethu ngeendlela ezininzi ezisekelwe kwiimveliso. Sipakisha iimveliso zethu ngeendlela ezininzi, ezinje,