4130 Aluia Steel Seamless Paipu

ʻO ka wehewehe pōkole:

4130 Alloy Steel Paipu:

ʻO 4130 paipu kila kila he kila haʻahaʻa i loaʻa ka chromium a me ka molybdenum e like me nā mea hoʻoikaika. Hāʻawi ia i kahi kaulike maikaʻi o ka ikaika, paʻakikī, a me ka weldability, i mea kūpono no nā noi e koi ai i ka ikaika kiʻekiʻe a me ka lōʻihi, e like me ka aerospace, automotive, a me nā ʻoihana ʻaila a me nā kinoea. ʻIke ʻia ka alloy no kona kūpaʻa luhi maikaʻi loa a hoʻohana maʻamau ʻia i nā ʻāpana hana e like me nā papa, shafts, a me nā pipelines. Hoʻohui, hiki ke hoʻomaʻamaʻa ʻia ke kila 4130 e hoʻomaikaʻi i kāna mau waiwai mechanical, e hoʻomaikaʻi hou i kāna hana ma nā wahi koi.

Nā kikoʻī o 4130 Steel Seamless Tube:

| Nā kikoʻī | ASTM A 519 |

| Papa | 4130 |

| Papa kuhikuhi | SCH20, SCH30, SCH40, XS, STD, SCH80, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| ʻAno | ʻAʻole ka lau |

| Puka | Rectangular, Poe, Square, Hydraulic Etc |

| Ka lōʻihi | 5.8M,6M & Koi ʻia ka lōʻihi |

| Hoʻopau | Wehe Pihe, Wehe Plain, Hehi |

| Palapala Hoao Mill | EN 10204 3.1 a i ʻole EN 10204 3.2 |

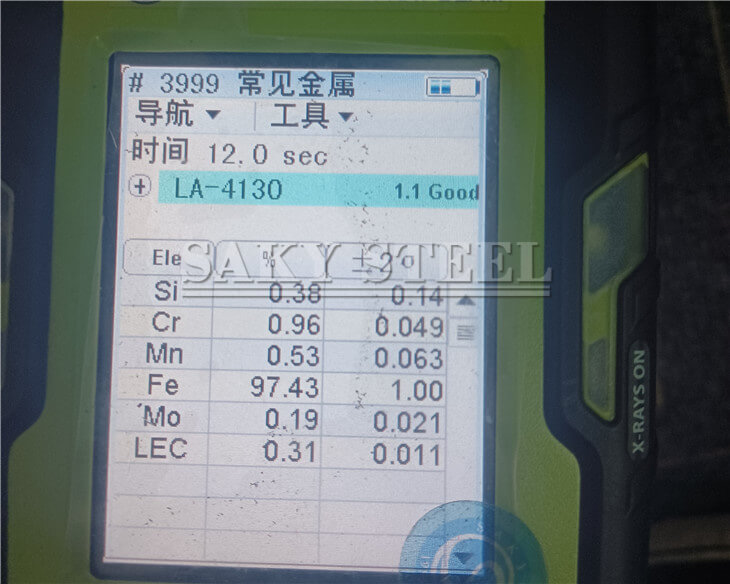

AISI 4130 Pipes Chemical Composition:

| Papa | C | Si | Mn | S | P | Cr | Ni | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | 0.025 | 0.035 | 0.08-1.10 | 0.50 | 0.15-0.25 |

Nā Pono Mechanical o 4130 Puʻupuʻu Paipu:

| Papa | ʻO ka ikaika uʻi (MPa) min | Elongation (% ma 50mm) min | ʻO ka ikaika 0.2% Hōʻoia (MPa) min |

| 4130 | MPa – 560 | 20 | MPa – 460 |

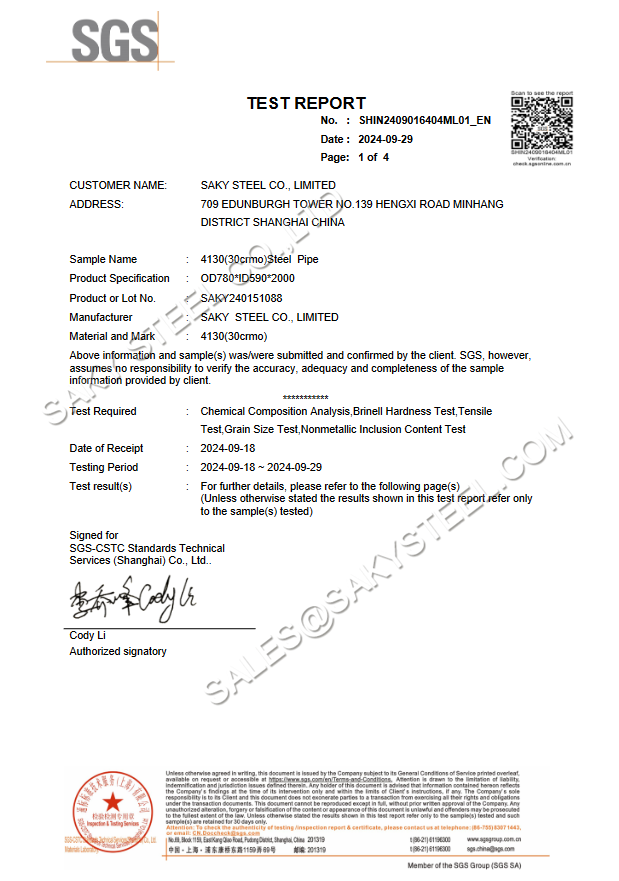

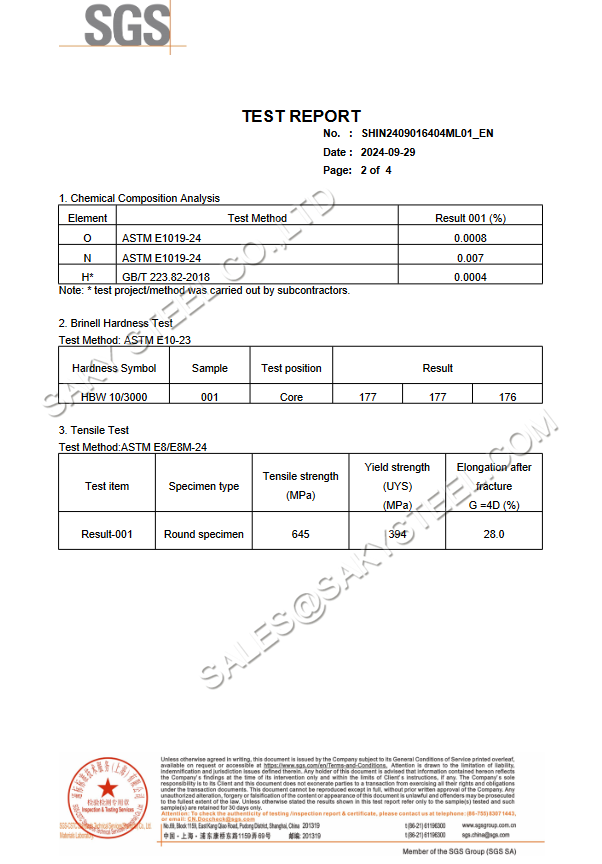

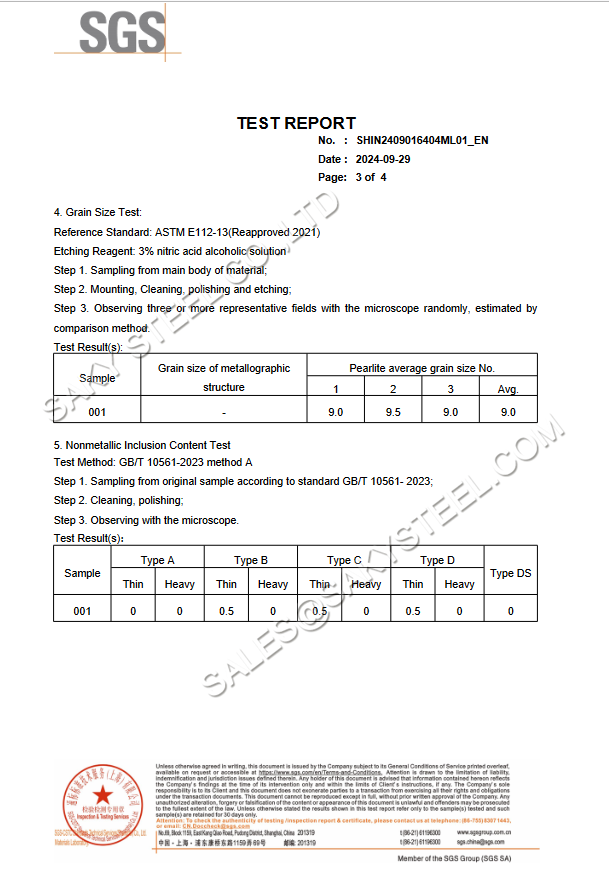

UNS G41300 Steel Round Tube Test:

4130 Alloy Steel Round Tube palapala hōʻoia:

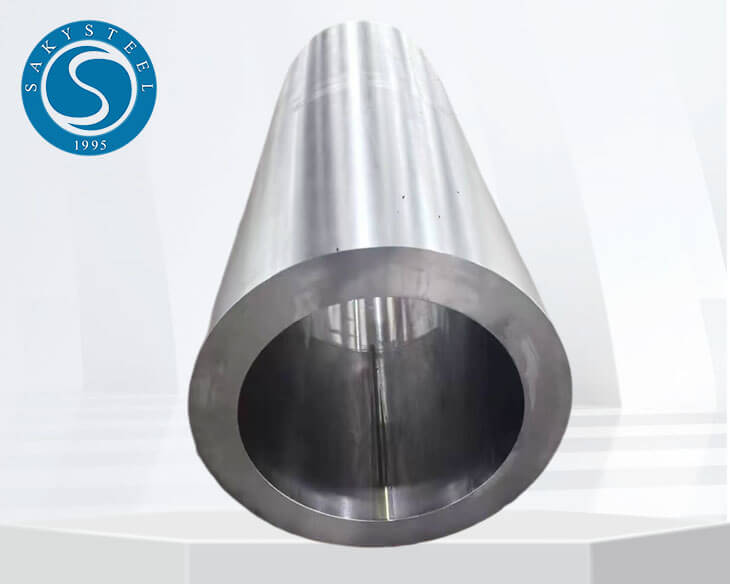

UNS G41300 Steel Round Tube Rough Huli:

ʻO ka hoʻohuli ʻino ʻana ke kaʻina hana mīkini mua i hoʻohana ʻia no ka wehe ʻana i nā mea nui mai kahi 4130 alloy steel seamless pipe. He mea koʻikoʻi kēia kaʻina hana i ka hana ʻana i ka mea hana i kahi ʻano kokoke loa ma mua o ka hoʻopau ʻana i nā hana. ʻO 4130 kila kila, iʻikeʻia no kona ikaika, paʻakikī, a me ka machinability maikaʻi, pane maikaʻi i kēia kaʻina hana, eʻae ai i ka laweʻana i nā mea pono. I ka wā o ka hoʻololi ʻana, hoʻohana ʻia ka mīkini hili a i ʻole CNC e ʻoki koke i ke anawaena o ka paipu, e hoʻomākaukau ana no ka huli pololei ʻana a i ʻole nā hana lua. Pono ke koho pono a me ka hoʻoluʻu no ka mālama ʻana i ka wela a hōʻoia i ka maikaʻi o ka ʻili a me ke ola mea hana.

Nā pōmaikaʻi o 4130 Alloy Steel Seamless Pipe:

1. High Strength-to-Weight Ratio: 4130 alloy steel hāʻawi i ka ikaika maikaʻi loa i ka mālama ʻana i kahi kaumaha haʻahaʻa haʻahaʻa, e kūpono ana i nā noi e koi ana i ka lōʻihi a me ke kaumaha o nā mea waiwai, e like me ka aerospace a me nā ʻoihana automotive.

2.Good Weldability: ʻOiai kona ikaika kiʻekiʻe, ʻike ʻia ke kila kila 4130 no kona weldability. Hiki ke wili ʻia me ka hoʻohana ʻana i nā ʻano hana like ʻole (TIG, MIG) me ka ʻole o ka pono o ka preheating nui, e hoʻolilo iā ia i mea maʻalahi no ka hana ʻana.

3.Toughness and Fatigue Resistance: Hāʻawi ka huila i ka paʻakikī kiʻekiʻe a me ke kūpaʻa luhi kiʻekiʻe, e kūpono ana i nā noi noi e like me ke kiʻekiʻe-press tubing a me nā mea mechanical i pili i ke koʻikoʻi.

4.Corrosion Resistance: ʻOiai ʻaʻole e like me ka corrosion-resistant e like me ke kila kila, hana maikaʻi ʻo 4130 alloy steel i nā wahi ʻoluʻolu ke uhi pono ʻia a mālama ʻia paha, e hoʻolōʻihi i kona ola i nā kūlana paʻakikī.

5.Maikaʻi Machinability: He mea maʻalahi ka 4130 kila kila i ka mīkini i ka hoʻohālikelikeʻana i nā mea kila ikaika'ē aʻe, e hana ana i ke kumu kūʻai i nā kaʻina hana, e like me ka huliʻana, ka wili, a me ka wili.

6.Versatile Applications: ʻO ka hana maʻemaʻe a me ka ikaika kiʻekiʻe e hana i ka 4130 alloy steel pipe i mea kūpono no nā noi koʻikoʻi e like me ka hydraulic tubing, ka ʻaila a me ke kinoea drilling, structural frameworks, and aerospace parts.

No ke aha e koho ai iā mākou?

1.With ma luna o 20 makahiki o ka hoao ana, ko makou hui o ka poe akamai e hōʻoiaʻiʻo kiʻekiʻe-notch maikaʻi ma kēlā me kēia papahana.

2. Mālama mākou i nā kaʻina hana hoʻomalu maikaʻi e hōʻoia i kēlā me kēia huahana i nā kūlana.

3.We hoʻohana i ka ʻenehana hou a me nā hoʻonā hou e hāʻawi i nā huahana ʻoi aku ka maikaʻi.

4.We hāʻawi aku i nā kumukūʻai hoʻokūkū me ka ʻole o ka hoʻohālikelike ʻana i ka maikaʻi, e hōʻoiaʻiʻo ana e loaʻa iā ʻoe ka waiwai maikaʻi loa no kāu hoʻopukapuka.

5.We hāʻawi aku i kahi laulā o nā lawelawe e hoʻokō i kāu mau pono a pau, mai ka kūkākūkā mua a hiki i ka hoʻouna hopeʻana.

6. ʻO kā mākou kūpaʻa i ka hoʻomau a me nā hana kūpono e hōʻoiaʻiʻo i kā mākou mau kaʻina hana i ke kaiapuni.

ʻO kā mākou lawelawe:

1.Quenching a me ka tempering

2.Vacuum wela mālama

3.Mirror-polished ili

4.Precision-milled pau

4.CNC machining

5.Precision wili

6.ʻokiʻoki i nā'āpana liʻiliʻi

7. Loaʻa i ka pololei e like me ka mold

Kiekie ikaika Alloy Pipe Packaging:

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka hopohopo kūikawā e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana ma nā ʻano he nui, e like me,