440C Stainless Steel Bar

Short Description:

440C stainless steel is a high-carbon martensitic stainless steel that is known for its excellent hardness, wear resistance, and corrosion resistance.

Stainless Steel 440C Bars:

440C stainless steel can be hardened to achieve high levels of hardness, typically around 58-60 HRC (Rockwell hardness scale).It belongs to the 400 series of stainless steels, which are characterized by having high carbon content, typically around 0.60-1.20%, and moderate corrosion resistance.It has excellent wear resistance, making it suitable for applications such as bearings, cutting tools, surgical instruments, and valve components.While not as corrosion-resistant as austenitic stainless steels (e.g., 304, 316), 440C offers good corrosion resistance in mild environments. It is more corrosion resistant than other high-carbon steels due to its chromium content.440C stainless steel can be heat-treated to achieve desired mechanical properties.

Specifications Of 440C Bar:

| Grade | 440A,440B |

| Standard | ASTM A276 |

| Surface | hot rolled pickled ,polished |

| Technology | Forged |

| Length | 1 to 6 Meters |

| Type | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Tolerance | ±0.5mm,±1.0mm,±2.0mm,±3.0mm or as per clients’ requirements |

| Raw Materail | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

Equivalent Grade of A276 Stainless Steel 440C Bars:

| STANDARD | WERKSTOFF NR. | UNS | JIS |

| SS 440C | 1.4125 | S44004 | SUS 440C |

Chemical Composition Of S44004 Bar:

| Grade | C | Mn | P | S | Si | Cr | Mo |

| 440C | 0.95-1.20 | 1.0 | 0.040 | 0.030 | 1.0 | 16.0-18.0 | 0.75 |

Mechanical properties of 440C Stainless Steel Bar:

| Type | Condition | Finish | Diameter or Thickness,in. [fmm] | Hardness HBW |

| 440C | A | hot-finish,cold-finish | all | 269-285 |

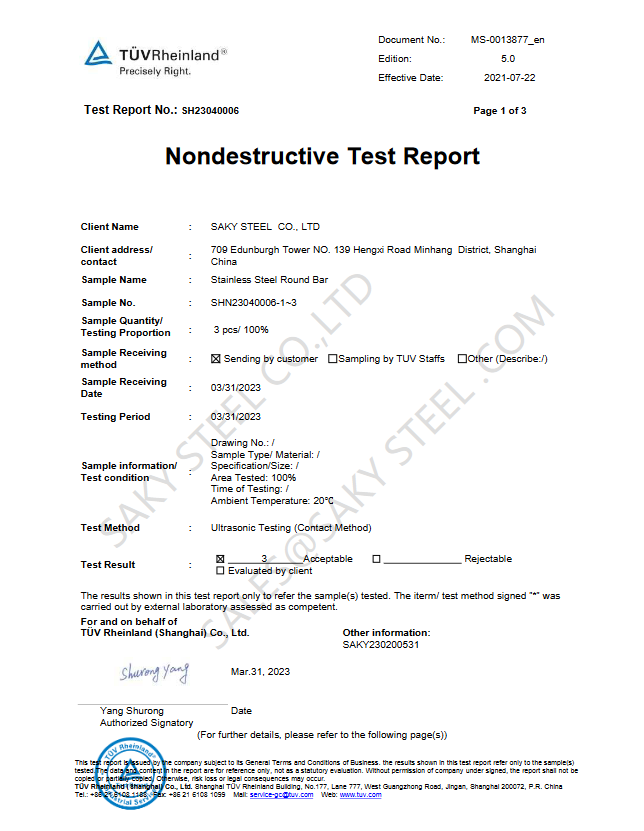

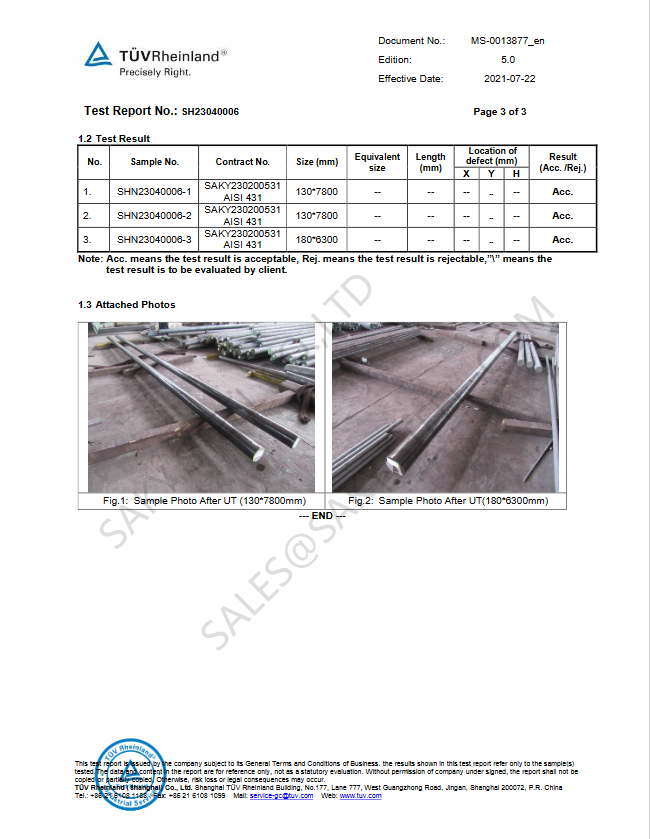

S44004 Stainless Steel Bar UT Test:

Testing Standard:EN 10308:2001 Quality class 4

Features & Benefits:

• After appropriate heat treatment, 440C stainless steel can achieve a high level of hardness, typically between 58-60 HRC, making it suitable for applications requiring high hardness.

• Due to its high carbon content and excellent heat treatment properties, 440C stainless steel exhibits outstanding wear resistance, making it suitable for various applications such as cutting tools, bearings, etc.

• While not as corrosion-resistant as austenitic stainless steels (e.g., 304, 316), 440C stainless steel still offers good corrosion resistance in suitable environments, primarily due to its high chromium content, which forms a protective chromium oxide surface layer.

•440C stainless steel can be effectively machined under appropriate conditions to meet various component requirements. However, due to its high hardness and strength, machining may be relatively challenging and requires suitable machining processes and tools.

• 440C stainless steel demonstrates good high-temperature stability, maintaining its hardness and wear resistance under elevated temperature conditions, making it suitable for applications in high-temperature environments.

• The mechanical properties of 440C stainless steel can be adjusted through heat treatment, such as hardness, strength, and toughness, to meet specific application requirements.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

What is 440C Stainless Steel?

440C stainless steel offers a balance of good wear resistance and moderate corrosion resistance in mild environments, with excellent hardenability. It shares similarities with 440B grade but has a slightly higher carbon content, resulting in higher hardness but slightly reduced corrosion resistance compared to 440B. It can achieve hardness of up to 60 Rockwell HRC and resists corrosion in typical domestic and mild industrial environments, with optimal resistance achieved below approximately 400°C tempering temperature. Surface preparation is crucial for best corrosion resistance, necessitating removal of scale, lubricants, foreign particles, and coatings. Its high carbon content allows for machining similar to annealed high-speed steel grades.

440C Stainless Steel Round Bar Application:

440C stainless steel round bars are widely used in knife making, bearings, tooling and cutting tools, medical instruments, valve components, and industrial equipment, where their high hardness, wear resistance, and moderate corrosion resistance make them ideal choices for critical components requiring excellent performance and long-term durability.

Welding of Stainless Steel 440C:

Due to its high hardness and ease of air hardening, welding of 440C stainless steel is infrequent. However, if welding becomes necessary, it is recommended to preheat the material to 260°C (500°F) and perform a post-weld annealing treatment at 732-760°C (1350-1400°F) for 6 hours, followed by slow furnace cooling to prevent cracking. To ensure similar mechanical properties in the weld as in the base metal, welding consumables with similar composition should be used. Alternatively, AWS E/ER309 may also be considered as a suitable option.

Our Clients

Feedbacks From Our Clients

400 series stainless steel rods have several notable advantages, making them favored in various applications.400 series stainless steel rods typically exhibit excellent corrosion resistance, making them resistant to oxidation, acids, salts, and other corrosive substances, suitable for harsh environments.These stainless steel rods are often free-machining, demonstrating excellent machinability. This feature makes them easy to cut, shape, and process.400 series stainless steel rods perform well in terms of strength and hardness, suitable for applications requiring high strength and wear resistance, such as the manufacturing of mechanical components.

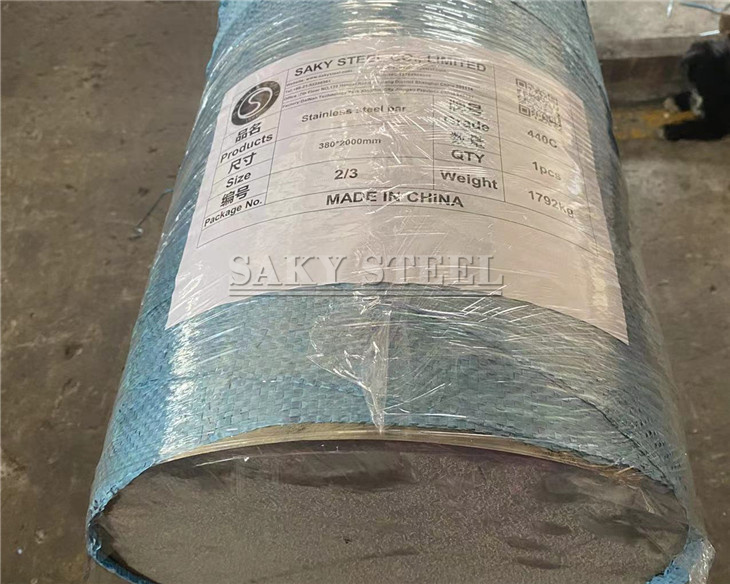

Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,