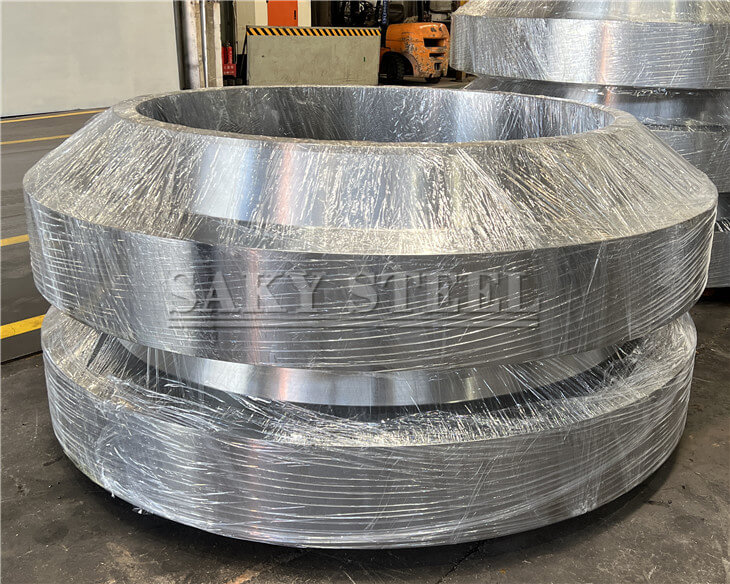

Forged Stainless Steel Rolled Rings

Short Description:

Forged stainless steel rolled rings, offering exceptional strength and corrosion resistance, ideal for demanding industrial applications such as oil, chemical, and machinery manufacturing.

Stainless Steel Forging Rings:

Forged stainless steel rings are renowned for their high strength, corrosion resistance, and heat resistance, making them ideal for use in industries such as oil and gas, chemical processing, aerospace, and machinery manufacturing. The forging process results in a denser internal structure and superior mechanical properties, allowing these rings to maintain stability and durability under extreme conditions. Additionally, forged stainless steel rings can be customized in size and shape to meet the precise and specialized requirements of various applications.SAKY STEEL specializes in the forging of custom seamless rolled rings from martensitic, austenitic, and precipitation hardening stainless steels. Each type has unique characteristics beneficial to specific applications.

Specifications of 304 Stainless Steel Forging:

| Grade | 304,316,316L,321 etc. |

| Standard | ASME SA-182 |

| Surface | Bright;Black; Peeled; Polished; Machined; Grinded; Turned; Milled |

| Flat bar blocks | up to 27" width and 15,000 lbs. |

| Cylinders and sleeves | up to 50" maximum O.D. and 65" maximum length |

| Discs and hubs | up to 50" diameter and 20,000 lbs. |

| Rolled, hand forged or mandrel forged rings | up to 84" maximum O.D. and 40" maximum length |

| Rounds, shafts and step shafts | up to 144" maximum length and 20,000 lbs |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

ASTM A182 Forged Stainless Steel Rolled Rings Test:

PT Test

UT Test

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

SAKY STTEL Provides Services

1.Heat treatment

2.Machining

3.Parting, splitting and segmenting

4.Shot blasting

5.Hardness testing

6.Ultrasonic inspection

7.Magnetic particle inspection

8.Mechanical analysis (charpy and tensile)

9.Chemical analysis

10.Positive material identification

Forged Stainless Steel Rings Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,