17-4 PH stainless steel—designated as UNS S17400—is a precipitation-hardening alloy celebrated for its remarkable strength, corrosion resistance, and adaptability to heat treatment. Its unique combination of mechanical robustness and chemical stability makes it a material of choice across demanding sectors such as aerospace, medical devices, chemical processing, and defense engineering.

When alternatives are required, equivalent materials to 17-4 PH include grades like DIN 1.4542 and AISI 630. These substitutes deliver similar performance characteristics, making them suitable for a broad range of industrial applications.

17-4PH Stainless Steel Grade

| ASTM/AISI | DIN | JIS | GB |

| 17-4PH/630 | 1.4542 | SUS630 | 05Cr17Ni4Cu4Nb |

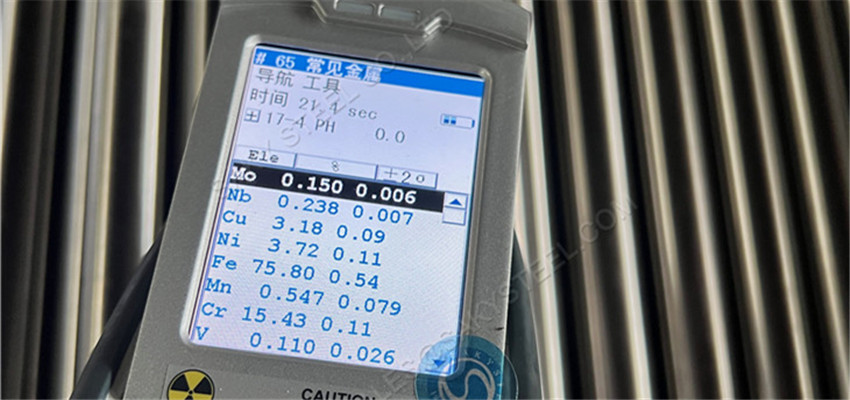

17-4PH Stainless Steel Chemical Composition

| C | Mn | Si | P | S | Cr | Ni | Cu | Mo |

| 0.07 | 1.0 | 1.0 | 0.04 | 0.03 | 15.0-17.5 | 3.0-5.0 | 3.0-5.0 | 0.50 |

• Chromium (15-17.5%): Provides corrosion resistance.

• Nickel (3-5%): Enhances toughness.

• Copper (3-5%): Crucial for precipitation hardening.

• Carbon (<0.07%): Maintains ductility and toughness.

17-4PH Stainless Steel echanical Properties

| Material | Condition | Tensile(ksi) | Yield 0.2% offset(ksi) | Elongation | Reduction of Area | Brinell Hardness | Rockwell Hardness |

| 17-4PH | H900 | 190 | 170 | 10% | 40% | 388-444 HB | 40-47 HRC |

| H925 | 170 | 155 | 10% | 44% | 375-429 HB | 38-45 HRC | |

| H1025 | 155 | 145 | 12% | 45% | 331-401 HB | 34-42 HRC | |

| H1075 | 145 | 125 | 13% | 45% | 311-375 HB | 31-38 HRC | |

| H1100 | 140 | 115 | 14% | 45% | 302-363 HB | 30-37 HRC | |

| H1150 | 135 | 105 | 16% | 50% | 277-352 HB | 28-37 HRC |

Key Properties of 17-4 PH Stainless Steel

1.Exceptional Strength: Delivers impressive tensile strength ranging from 1000 to 1400 MPa, making it ideal for high-load applications.

2.Superior Corrosion Resistance: Comparable to 304 stainless steel, yet offers enhanced protection against stress-corrosion cracking in harsh environments.

3.Flexible Heat Treatability: Mechanical properties can be precisely adjusted through precipitation-hardening processes such as H900, H1025, and H1150.

4.Outstanding Toughness: Maintains structural integrity even under extreme temperatures and challenging service conditions.

Heat Treatment and Precipitation Hardening

What sets 17-4 PH stainless steel apart is its remarkable capacity for precipitation hardening—a heat treatment process that significantly enhances its mechanical performance. By heating the alloy to precise temperatures followed by controlled aging, its properties can be finely tuned.Typical heat-treated conditions include:

• H900: Provides the highest strength levels.

• H1150: Offers superior corrosion resistance and increased toughness.

This adaptability enables engineers to tailor the material’s characteristics to meet the specific demands of a wide range of industrial applications.

Applications of 17-4 PH Stainless Steel

The superior properties of 17-4 PH stainless steel make it ideal for a wide range of applications:

• Aerospace: Utilized in structural assemblies, turbine components, and high-performance fasteners.

• Medical Field: Ideal for precision surgical tools and durable implant devices.

• Chemical Processing: Employed in reactors and equipment that endure aggressive chemical exposure.

• Oil & Gas: Common in pump shafts, valves, and other components subject to high pressure and corrosive media.

• Defense Sector: Trusted for manufacturing robust components in military-grade hardware.

These applications underscore its reliability in challenging environments where both strength and longevity are essential.

Why Choose 17-4 PH Stainless Steel?

17-4 PH stainless steel becomes the preferred solution when applications call for:

• Exceptional mechanical strength to withstand heavy loads and stress.

• Reliable corrosion resistance in aggressive or demanding environments.

• Flexible heat treatment options to fine-tune performance characteristics.

Its proven durability and adaptability make it a trusted choice across industries that demand high-performance, long-lasting materials.

Conclusion

Blending high strength, excellent corrosion resistance, and remarkable adaptability, 17-4 PH stainless steel is a superior option for mission-critical applications. When compared to conventional grades like 304 and 316, it distinguishes itself with outstanding reliability under harsh conditions. Its availability at competitive prices—particularly in markets like India—further enhances its appeal for diverse industrial uses, delivering both performance and value.

Post time: May-07-2025