Lisebelisoa tsa Shaft tse Khanyang

Tlhaloso e Khutšoanyane:

Lekola litšepe tse tšoarellang, tse matla haholo bakeng sa lisebelisoa tsa indasteri le mochini o boima. Lisaese tse ikhethileng lia fumaneha.

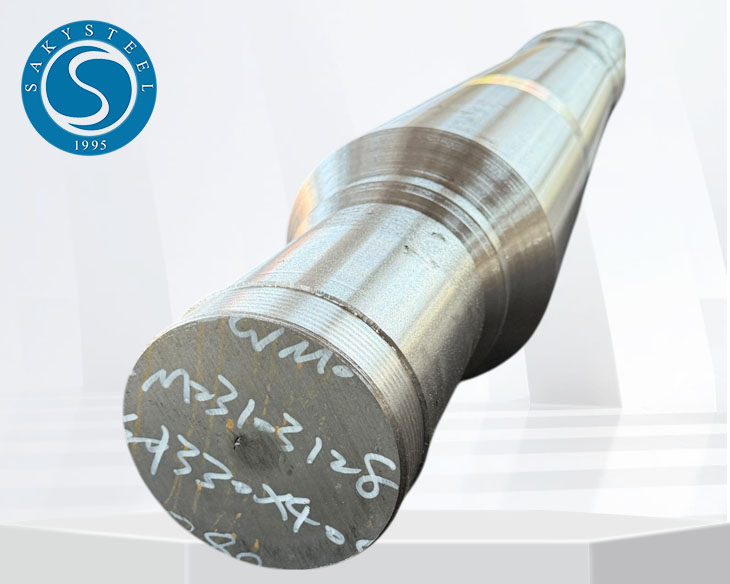

Shaft ea tšepe e entsoeng

Forged Steel Shaft ke karolo ea mochini o matla haholo o entsoeng ka mokhoa oa ho qhekella, moo tšepe e futhumatsang le ho bopeha tlas'a khatello e matla ho fihlela ts'ebetso e tšoarellang le ho ts'epahala. Ts'ebetso ena e ntlafatsa sebopeho sa lijo-thollo tsa thepa, e matlafatsa ho tiea ha eona, ho hanyetsa mokhathala, le matla a ho jara mojaro. Li-shafts tse entsoeng ka tšepe li sebelisoa haholo liindastering tse kang likoloi, sefofane, tlhahiso ea matla le mechine e boima, moo ho sebetsa tlas'a maemo a boima ho leng bohlokoa. Li ka hlophisoa ho latela boholo, sebopeho, le sebopeho sa thepa ho fihlela litlhoko tse ikhethileng tsa indasteri, ho netefatsa ts'ebetso e nepahetseng le bophelo bo bolelele.

Litlhaloso tsa High-Strength Shaft Forgings:

| Litlhaloso | ASTM A182,ASTM A105,GB/T 12362,GB/T 1031 |

| Lintho tse bonahalang | Tšepe ea motsoako, tšepe ea carbon, tšepe ea Carburizing, tšepe e tingoeng le e halefileng |

| Kereiti | Carbon Steel:4130,4140,4145,S355J2G3+N,S355NL+N,C20,C45,C35, joalo-joalo. |

| Tšepe e se nang Mokelikeli: 17-4 PH, F22,304,321,316/316L, joalo-joalo. | |

| Tool Steel: D2 / 1.2379, H13 / 1.2344, 1.5919, joalo-joalo. | |

| Surface Finish | E ntšo, e Khanyang, joalo-joalo. |

| Phekolo ea mocheso | Ho tloaeleha, Ho Aneha, Ho tima le ho halefisa, ho tima holim'a metsi, ho thatafatsa linyeoe |

| Mochini | CNC Turning,CNC Milling,CNC Boring,CNC Grinding,CNC Drilling |

| Mochini oa Gear | Gear Hobbing,Gear Milling,CNC Gear Milling,Gear Cutting,spiral gear cutting,Gear Cutting |

| Setifikeiti sa Teko sa Mill | EN 10204 3.1 kapa EN 10204 3.2 |

Likopo tsa Precision Bright Shaft Forgings:

Forged Steel Shafts ke likarolo tse feto-fetohang tse sebelisoang haholo liindastering tse ngata ka lebaka la matla a tsona a ikhethang, ho tšoarella le ho hana mokhathala. Mona ke tse ling tsa lisebelisoa tsa bona tsa bohlokoa:

1. Indasteri ea Likoloi: Li-Crankshafts, camshafts, le li-axle likoloing, literaka le likoloi tse boima.

2. Indasteri ea Aerospace: Li-shafts tse entsoeng ka mokhoa o nepahetseng bakeng sa li-jet engines le li-rotor tsa li-helicopter.

3. Pheliso ea Motlakase: Litšepe tsa turbine lifemeng tsa motlakase (mouoane, khase, le li-turbine tsa motlakase o fehlang metsi).

4. Mechini ea Liindasteri: Li-shafts tse boima tsa li-compressor, lipompo, le lisebelisoa tsa lisebelisoa.

5. Indasteri ea Oli le Khase: Li-shafts tsa ho cheka le li-shafts tsa pompo tse sebelisoang ho hlahloba le ho ntša oli.

6. Indasteri ea Maoatleng: Li-propeller shafts le li-rudder stocks bakeng sa likepe le likepe tse tsamaeang ka tlas'a metsi.Litšepe tse entsoeng ka tšepe tse sa khoneng ho bola bakeng sa thepa ea kantle ho naha.

7. Lisebelisoa tsa Kaho le Merafo: Khanna li-shafts le li-roller shafts ka li-excavator, bulldozers, le lisebelisoa tsa merafo.

Likarolo tsa Bright Shaft Forgings:

1.Matla le Tšireletseho:Li-shafts tsa forged li tsebahala ka matla a tsona a ikhethang le ho tšoarella ha nako e telele. Ts'ebetso ea ho qhekella e ntlafatsa ho tsamaisana ha sebopeho sa lijo-thollo tsa tšepe, e leng ho ntlafatsang haholo thepa ea eona ea mochini le ho hanyetsa mokhathala.

2. Thepa e Ntlafalitsoeng ea Metallurgical:Ka ts'ebetso ea ho qhekella, thepa e ba le ntlafatso e kholo, e hlahisang lisebelisoa tse phahameng tsa metallurgic, ho kenyelletsa le phallo e ntle ea lijo-thollo. Sena se lebisa ho toughness e ntlafetseng le ho ntlafatsa tshebetso ka kakaretso.

3.Ho nepahala ho phahameng:Forging e etsa hore ho be le sebopeho se nepahetseng sa li-shafts, ho fihlela mamello e tiileng le sephetho se phahameng sa bokaholimo, ho netefatsa likarolo tsa boleng bo holimo bakeng sa lits'ebetso tsa bohlokoa.

4.Tailored Customization:Ts'ebetso ea ho qhekella e fana ka monyetla oa ho theha li-shaft tse nang le libopeho tse ikhethileng, boholo le thepa ea thepa, e fanang ka bokhoni ba ho fihlela litlhoko tse ikhethang tsa boenjiniere le litlhaloso tsa moetlo.

5.Ho Fokotsa Tšila ea Lintho tse Nyenyane:Ha ho bapisoa le mekhoa e meng ea tlhahiso, ho fereka ho sebetsa hantle haholoanyane mabapi le tšebeliso ea thepa, ho hlahisa litšila tse fokolang. Sena se etsa hore e be khetho e sebetsang hantle le e tšoarellang tikolohong.

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS ,TUV,BV 3.2.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

Ho Paka Litšepe Tsa Forged Steel:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,