Stainless Steel 329 Wire

Short Description:

Stainless Steel 329 Wire (UNS S32900 / AISI 329) with excellent corrosion and heat resistance. Available in coil, spring, and welding wire forms. Certified to ASTM A580 standard.

Stainless Steel 329 Wire (UNS S32900, AISI 329) is a duplex stainless steel combining high strength with excellent resistance to corrosion, especially in marine and chemical environments. It offers superior performance against chloride stress corrosion cracking and is ideal for applications that require both toughness and durability at high temperatures.

| Specifications of Stainless Steel 329 Wire: |

| Specifications | ASTM A580 |

| Grade | 329 |

| Wire diameter | 0.50 mm to 10 mm |

| Surface | Bright, Dull |

| Condition | Annealed / Hard / As Drawn |

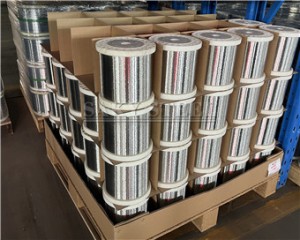

| Form | Wire Bobbin, Wire Coil, Filler Wire, Coils |

Available Wire Diameters

- Ultra-Fine Wire: 0.10 mm to 0.30 mm

- Fine Wire: 0.31 mm to 1.00 mm

- Medium Wire: 1.01 mm to 3.00 mm

- Standard Wire: 3.01 mm to 10.00 mm

| Dimensional Tolerances: |

| Wire Diameter Range | Standard Tolerance | Precision Tolerance (Available on Request) |

|---|---|---|

| 0.10 mm – 0.30 mm | ±0.005 mm | ±0.003 mm |

| 0.31 mm – 1.00 mm | ±0.010 mm | ±0.005 mm |

| 1.01 mm – 3.00 mm | ±0.020 mm | ±0.010 mm |

| 3.01 mm – 10.00 mm | ±0.030 mm | ±0.015 mm |

| Chemical Composition UNS N02200 Wire: |

| Grade | C | Mn | Si | Mo | P | Cr | S | Fe | Ni |

| UNS S32990 | 0.08 |

2.0 | 1.0 |

1.0-2.0 | 0.035 | 23.0-28.0 | 0.02 | Bal | 2.5-5.0 |

| Physical and Mechanical Properties : |

| Property | Units | Value |

|---|---|---|

| Density | g/cm³ | 7.8 |

| Melting Range | °C | 1380-1430 |

| Electrical Resistivity at 20°C | μΩ·cm | 80 |

| Thermal Conductivity at 20°C | W/m·K | 15 |

| Coefficient of Thermal Expansion (20-100°C) | 10⁻⁶/K | 13.0 |

| Specific Heat at 20°C | J/kg·K | 470 |

| Young’s Modulus | GPa | 200 |

| Magnetic Permeability | - | Slightly magnetic (ferrite phase) |

| Maximum Service Temperature | °C | 300 |

| Condition | Tensile Strength (MPa)* | Yield Strength (MPa)* | Elongation (%)* | Hardness* |

|---|---|---|---|---|

| Annealed | 750-850 | 450-550 | 25-35 | 240-270 HB |

| Quarter Hard | 850-950 | 650-750 | 15-25 | 270-300 HB |

| Half Hard | 950-1050 | 750-850 | 10-15 | 300-330 HB |

| Full Hard | 1050-1200 | 850-1000 | 5-10 | 330-360 HB |

| Spring Temper | 1200-1400 | 1000-1200 | 2-5 | 360-400 HB |

| Key Features of 329 Wire : |

-

Duplex structure (austenitic + ferritic) with high strength and good toughness.

-

Excellent resistance to corrosion, especially in chloride and marine environments.

-

Good heat and oxidation resistance.

-

Higher yield strength than 304/316 stainless steel.

-

Good weldability and formability.

-

Partly magnetic.

-

Ideal for chemical, marine, and heat exchanger applications.

| UNS S32900 Wire Applications: |

-

Marine and chemical processing equipment

-

Heat exchangers and condensers

-

Pressure vessels and piping systems

-

Pump shafts, valves, and fasteners

-

Pulp and paper industry machinery

-

Oil and gas equipment

-

Welding and spring wire production

| Handling and Storage Recommendations : |

-

Keep materials in a clean, dry, and well-ventilated area, away from chemical vapors or contaminants.

-

Do not store near or in contact with carbon steel to avoid iron contamination that may reduce corrosion resistance.

-

Retain the original protective wrapping until the material is ready for use.

-

Use clean gloves when handling to prevent surface contamination from oils, sweat, or salts.

-

For extended storage, apply extra protection against moisture and airborne pollutants.

-

Avoid chloride-rich environments to prevent pitting or crevice corrosion.

-

Clean and passivate any surface that has been exposed to machining, welding, or contamination.

-

When handling, use stainless steel or plastic-coated tools to prevent cross-contamination.

-

Store and process stainless steel separately from carbon steel products to maintain surface integrity.

| FAQ : |

Q1: What is Stainless Steel 329 used for?

A: It’s used in chemical, marine, and industrial environments where both corrosion resistance and strength are required.

Q2: Is 329 stainless steel magnetic?

A: Yes, it has partial magnetism due to its duplex structure (austenitic + ferritic).

Q3: What standards cover 329 stainless steel wire?

A: ASTM A580, ASTM A276, EN 1.4460, and UNS S32900.

Q4: What surface finishes are available?

A: Bright, matte, pickled, or polished finish according to customer needs.

| Why Choose SAKYSTEEL : |

Reliable Quality – Our stainless steel bars, pipes, coils, and flanges are manufactured to meet international standards such as ASTM, AISI, EN, and JIS.

Strict Inspection – Every product undergoes ultrasonic testing, chemical analysis, and dimensional control to ensure high performance and traceability.

Strong Stock & Fast Delivery – We maintain regular inventory of key products to support urgent orders and global shipping.

Customized Solutions – From heat treatment to surface finish, SAKYSTEEL offers tailor-made options to match your exact requirements.

Professional Team – With years of export experience, our sales and technical support team ensures smooth communication, quick quotations, and full documentation service.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

| SAKY STEEL’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,