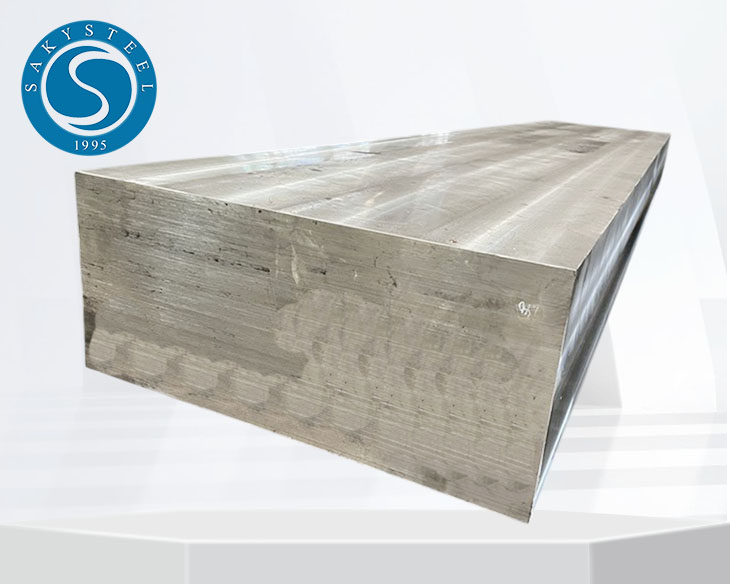

P750 Nonmagnetic Steel

Short Description:

P750 Nonmagnetic Steel offers high strength, excellent corrosion resistance, and stable non-magnetic properties, ideal for precision instruments, molds, and measurement devices. Available in bars, plates, and custom sizes with EN, ASTM, and JIS standards.

P750 Nonmagnetic Steel is a high-strength austenitic alloy designed for applications requiring stable non-magnetic performance and excellent mechanical properties. It combines corrosion resistance with superior toughness and machinability.

| Grade | N850,P750,P690,P550 etc. |

| Size |

Forged Blocks / Squares:Thickness/Width: 100 mm – 400 mm Length: up to 2000 mm Hot Rolled / Forged Round Bars:Diameter: Ø 50 mm – Ø 400 mm Length: 2 m – 6 m (can be customized, up to 8 m) |

| Technology | Smelting & Refining,Hot Working,Heat Treatment,Cold Working,etc. |

| Surface Finish | Bright, Peeled, Polished, Turned, Pickled |

| Chemical Composition P750 Nonmagnetic Steel: |

| C | Cr | Mn | Ni | Mo | N | Si |

| 0.05 | 17.0-19.0 | 2.0 | 12.0-15.0 | 2.5 | 0.2 | 1.0 |

| Mechanical Properties : |

| TEXT | OD | KSI | N/MM |

| Yield Strength (min.) 0,2%-offset method: | OD max. 91/2“ | 160 ksi | 1104 N/mm² |

| Tensile Strength (min.): | 165 ksi | 1139 N/mm² | |

| Elongation (min.): | 10% | 10% | |

| Reduction of area (min.): | 50% | 50% | |

| Impact energy (min.): | 80 ft.lb | 110 J | |

| Endurance Strength / N=10⁵ (min.): | ± 80 ksi | ± 550 N/mm² | |

| Hardness Brinell: (min.): | 300-420 HB | 300-420 HB |

| Applications of P750 Nonmagnetic Steel: |

-

Precision Measuring Instruments

Used in micrometers, gauges, and precision tools where magnetic interference must be avoided. -

Electronic and Medical Equipment

Ideal for MRI-compatible components, medical sensors, and electronic housings requiring non-magnetic properties. -

Molds and Tooling

Applied in high-strength nonmagnetic mold bases and inserts to prevent distortion or attraction in magnetic fields. -

Aerospace and Defense Components

Suitable for aircraft instruments, navigation devices, and magnetic-sensitive assemblies. -

Marine and Offshore Engineering

Used in subsea tools, fasteners, and structures where both corrosion resistance and nonmagnetic performance are critical. -

Chemical and Petrochemical Processing

For valves, pumps, and instrumentation exposed to corrosive environments and requiring non-magnetic stability.

| FAQ |

Q1: What is P750 Nonmagnetic Steel?

A1: P750 is a high-strength austenitic stainless steel designed to maintain stable non-magnetic properties even after cold working. It combines excellent corrosion resistance, toughness, and machinability, making it ideal for precision and magnetic-sensitive applications.

Q2: Is P750 steel completely non-magnetic?

A2: Yes. P750 maintains a magnetic permeability of ≤1.01 µ, ensuring it remains effectively non-magnetic even under mechanical stress or after machining.

Q3: What are the main advantages of P750 compared with standard stainless steels?

A3: P750 offers higher strength, better non-magnetic stability, and improved corrosion resistance than standard grades like 304 or 316. It also performs well under both cryogenic and elevated temperatures.

Q4: What are the typical applications of P750 nonmagnetic steel?

A4: It is widely used in measuring instruments, medical and electronic equipment, mold bases, marine components, and chemical process instruments.

Q5: Can P750 be machined and welded easily?

A5: Yes. P750 can be machined and welded using conventional stainless steel techniques, but to preserve nonmagnetic properties, heat input should be controlled, and post-weld cooling should be gradual.

| Why Choose SAKYSTEEL : |

Reliable Quality – Our stainless steel bars, pipes, coils, and flanges are manufactured to meet international standards such as ASTM, AISI, EN, and JIS.

Strict Inspection – Every product undergoes ultrasonic testing, chemical analysis, and dimensional control to ensure high performance and traceability.

Strong Stock & Fast Delivery – We maintain regular inventory of key products to support urgent orders and global shipping.

Customized Solutions – From heat treatment to surface finish, SAKYSTEEL offers tailor-made options to match your exact requirements.

Professional Team – With years of export experience, our sales and technical support team ensures smooth communication, quick quotations, and full documentation service.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

| Custom Processing Capabilities: |

-

Cut-to-size service

-

Polishing or surface conditioning

-

Slitting into strips or foil

-

Laser or plasma cutting

-

OEM/ODM welcome

SAKY STEEL supports custom cutting, surface finish adjustments, and slit-to-width services for N7 nickel plates. Whether you need thick plates or ultra-thin foil, we deliver with precision.

| SAKY STEEL’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,