P550 nonmagnetic steel

Short Description:

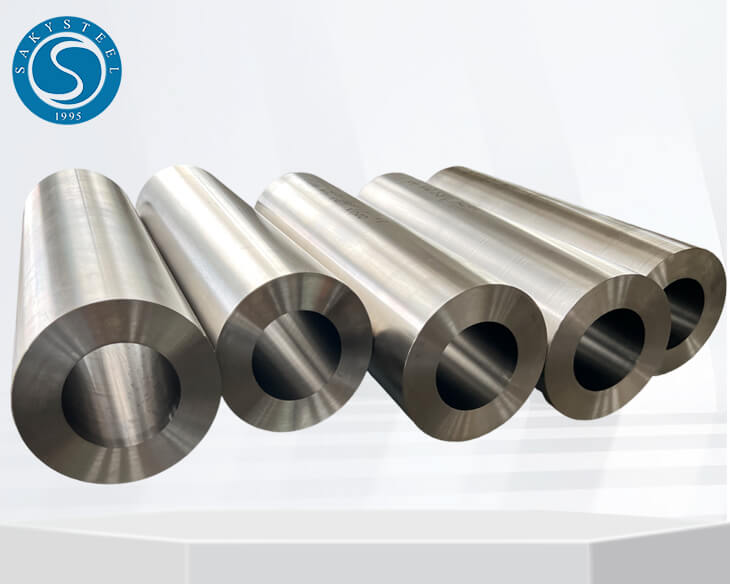

P550 nonmagnetic steel offers low permeability with μr ≤ 1.03, making it ideal for MWD/LWD applications. It provides excellent machinability, corrosion resistance, and comes with full MTRs and UT testing. Available in bars and tubes, P550 can be supplied in demagnetized condition.

P550 nonmagnetic steel is a high-performance material designed for applications requiring low magnetic permeability, such as Measurement While Drilling (MWD) and Logging While Drilling (LWD) tools. With a relative permeability (μr) of ≤ 1.03, P550 ensures minimal interference with magnetic fields, making it ideal for sensitive drilling and measurement operations.

This nonmagnetic steel is known for its excellent mechanical properties, including high strength, corrosion resistance, and good weldability, which make it suitable for demanding environments in the oil and gas, mining, and geophysical industries. P550 can be supplied in bars, rods, and tubes with full material test reports (MTR) and ultrasonic testing (UT), ensuring high quality and compliance with international standards.

| Grade | N850,P750,P690,P550 etc. |

| Size |

Forged Blocks / Squares:Thickness/Width: 100 mm – 400 mm Length: up to 2000 mm Hot Rolled / Forged Round Bars:Diameter: Ø 50 mm – Ø 400 mm Length: 2 m – 6 m (can be customized, up to 8 m) |

| Technology | Smelting & Refining,Hot Working,Heat Treatment,Cold Working,etc. |

| Surface Finish | Bright, Peeled, Polished, Turned, Pickled |

| Chemical Composition P550 Nonmagnetic Steel: |

| C | Cr | Mn | Ni | Mo | N |

| 0.06 | 18.0-20.0 | 20.5-21.6 | 1.4 | 0.50 | 0.60 |

| Mechanical Properties : |

| TEXT | OD | KSI | N/MM |

| Yield Strength (min.) 0,2%-offset method: | OD up to 9 1/4“ | 140 ksi | 965 N/mm² |

| OD 9 1/2“ and larger | 130 ksi | 900 N/mm² | |

| Tensile Strength (min.): | 150 ksi | 1035 N/mm² | |

| Elongation (min.): | 20% | 20% | |

| Reduction of area (min.): | 50% | 50% | |

| Impact energy (min.): | 60 ft.lb | 82 J | |

| Endurance Strength / N=10⁵ (min.): | ± 80 ksi | ± 550 N/mm² | |

| Hardness Brinell: (min.): | 335-450 HB | 335-450 HB |

| Applications of P550 Nonmagnetic Steel: |

P550 nonmagnetic steel is widely used in industries where low magnetic permeability is critical. Key applications include:

-

MWD (Measurement While Drilling) & LWD (Logging While Drilling): P550 is essential in the construction of measurement and logging tools used in directional drilling, where minimal magnetic interference is required to ensure accurate readings.

-

Geophysical Instruments: P550 is used in geophysical instruments and tools for seismic surveys, well logging, and other sensitive measurements, where magnetic fields could otherwise distort data.

-

Drill Collars & Tool Housings: P550 nonmagnetic steel is used to manufacture drill collars and tool housings, which must remain unaffected by magnetic fields during drilling operations.

-

Magnetic Shielding: Due to its low permeability, P550 is used in the production of magnetic shielding components, protecting sensitive electronic equipment from external magnetic interference.

-

Medical Equipment & Research: P550 is also applied in the production of medical instruments and research tools, where precision and low magnetic interference are essential.

| FAQ |

-

What is P550 nonmagnetic steel?

P550 is a high-performance steel with low magnetic permeability (μr ≤ 1.03), ideal for MWD and LWD tools. -

What are the applications of P550?

Used in MWD/LWD tools, drill collars, geophysical instruments, magnetic shielding, and medical equipment. -

Can P550 be supplied demagnetized?

Yes, P550 can be delivered in a demagnetized state with zero residual magnetism. -

What sizes are available?

P550 is available in bars, rods, and tubes with custom sizes upon request. -

What is the mechanical strength of P550?

P550 offers high strength, corrosion resistance, and excellent machinability.

| Why Choose SAKYSTEEL : |

Reliable Quality – Our stainless steel bars, pipes, coils, and flanges are manufactured to meet international standards such as ASTM, AISI, EN, and JIS.

Strict Inspection – Every product undergoes ultrasonic testing, chemical analysis, and dimensional control to ensure high performance and traceability.

Strong Stock & Fast Delivery – We maintain regular inventory of key products to support urgent orders and global shipping.

Customized Solutions – From heat treatment to surface finish, SAKYSTEEL offers tailor-made options to match your exact requirements.

Professional Team – With years of export experience, our sales and technical support team ensures smooth communication, quick quotations, and full documentation service.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

| Custom Processing Capabilities: |

-

Cut-to-size service

-

Polishing or surface conditioning

-

Slitting into strips or foil

-

Laser or plasma cutting

-

OEM/ODM welcome

| SAKY STEEL’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,