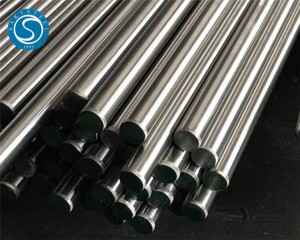

309 / 309S / 309H Stainless Steel Bar

Short Description:

SakySteel supplies 309, 309S, and 309H austenitic stainless steel bars with excellent oxidation resistance, high-temperature strength, and corrosion resistance. Ideal for furnaces, boilers, and heat exchangers.

309, 309S, and 309H austenitic stainless steel bars are high-temperature alloys designed for excellent oxidation and heat resistance up to 1100°C. With a balanced composition of chromium and nickel, these grades provide superior strength, corrosion resistance, and thermal stability. 309S offers lower carbon content for better weldability, while 309H contains higher carbon for enhanced high-temperature strength. Commonly used in furnaces, boilers, heat exchangers, and chemical processing equipment, SakySteel supplies these bars in hot-rolled, cold-drawn, and polished conditions, ensuring reliable performance under extreme environments.

| Specifications of 316/316L SS round bar: |

| Specifications | ASTM A276 |

| Grade | 309 / 309S / 309H |

| Length | 1000 mm – 6000 mm or as requested |

| Diameter Range | 10 mm – 200 mm (custom available) |

| Technology | Hot Rolled / Forged / Cold Drawn |

| Surface Finish | Bright, Peeled, Polished, Turned, Pickled |

| Form | Round, Square, Flat, Hexagonal |

| 309, 309S, and 309H stainless steel bar Equivalent Grades: |

| Grade | UNS | EN/W.Nr. | EN Designation | AISI/SAE | Japanese JIS |

|---|---|---|---|---|---|

| 309 | S30900 | 1.4833 | X12CrNi23-13 | 309 | SUS 309 |

| 309S | S30908 | 1.4833 | X12CrNi23-13 | 309S | SUS 309S |

| 309H | S30909 | – | – | 309H | – |

| Chemical Composition SS 309 309S 309H Round Bar: |

| Element | 309 (%) | 309S (%) | 309H (%) |

|---|---|---|---|

| Carbon (C) | 0.20 max | 0.08 max | 0.04-0.10 |

| Chromium (Cr) | 22.0-24.0 | 22.0-24.0 | 22.0-24.0 |

| Nickel (Ni) | 12.0-15.0 | 12.0-15.0 | 12.0-15.0 |

| Manganese (Mn) | 2.0 max | 2.0 max | 2.0 max |

| Silicon (Si) | 0.75 max | 0.75 max | 0.75 max |

| Phosphorus (P) | 0.045 max | 0.045 max | 0.045 max |

| Sulfur (S) | 0.030 max | 0.030 max | 0.030 max |

| Nitrogen (N) | 0.11 max | 0.11 max | – |

| Iron (Fe) | Balance | Balance | Balance |

| Physical and Mechanical Properties : |

| Property | Value |

|---|---|

| Density | 7.9 g/cm³ (0.285 lb/in³) |

| Melting Range | 1480-1530°C (2500-2590°F) |

| Modulus of Elasticity at 20°C | 196 GPa (28.5 × 10⁶ psi) |

| Electrical Resistivity at 20°C | 0.78 Ω·mm²/m (78 microhm-cm) |

| Thermal Conductivity at 100°C | 15 W/m·K (9.0 BTU·hr/ft²/ft/°F) |

| Coefficient of Thermal Expansion (20-100°C) | Approximately 9.7 × 10⁻⁶ /°F |

| Specific Heat Capacity | 500 J/kg·K (0.12 BTU/lb·°F) |

| Property | Typical Value |

|---|---|

| Tensile Strength (min) | 515 MPa (75,000 psi) |

| Yield Strength (0.2% Offset, min) | 205 MPa (30,000 psi) |

| Elongation in 50mm (min) | 40% |

| Hardness (max) | 217 HB (95 HRB) |

| Heat Treatment: |

For optimum performance, 309, 309S, and 309H stainless steels should undergo the following recommended heat treatment procedures:

-

Solution Annealing: Heat the material to 1832–2101°F (1000–1150°C), then quench rapidly to dissolve carbides and achieve maximum corrosion resistance.

-

Sigma Phase Restoration: Prolonged service between 1202–1742°F (650–950°C) may cause embrittlement due to sigma phase formation. Performing a solution anneal at 2012–2102°F (1100–1150°C) helps restore ductility and toughness.

-

Hot Forming: For hot working, heat evenly to 1742–2192°F (950–1200°C). After forming, a final annealing treatment at 1832–2101°F (1000–1150°C) followed by rapid cooling is recommended to maintain structure stability.

These grades cannot be hardened by heat treatment. The higher carbon levels in standard 309 and 309H enhance creep strength but can increase susceptibility to carbide precipitation during welding or extended exposure at intermediate temperatures. For applications requiring extensive welding, 309S, with its lower carbon content, is the preferred option.

| In-Site Test Items Applicable for Bars: |

To ensure the highest quality and performance, all SAKY STEEL bar products can be tested through a comprehensive range of in-site inspections. These tests verify chemical composition, mechanical integrity, and microstructural stability directly on materials before shipment or after processing.

| No. | Test Item | Description | Applicable Materials / Range | Note |

|---|---|---|---|---|

| 1 | In-situ Hardness Test | Measures surface hardness (HB/HRC/HV) to verify heat treatment or forging condition | All bar types — stainless steel, nickel alloys, titanium, aluminum | Standard test for bars |

| 2 | In-situ Metallographic Test | Examines grain structure, carbide distribution, and phase ratio | Stainless steel, nickel alloy, titanium | Detects overheating or improper heat treatment |

| 3 | In-situ Chemical Composition Test (PMI) | Confirms material grade and chemical composition using XRF or OES | All metallic bars | Prevents material mix-up |

| 4 | Residual Stress Test | Evaluates internal stress after heat treatment or machining | Steel, nickel, titanium bars | Prevents deformation or cracking |

| 5 | Stress and Strain Test | Determines mechanical properties such as yield strength and modulus | Structural or high-strength bars | Optional mechanical verification |

| 6 | Non-destructive Test of Ferrite Number | Measures FN value and ferrite-austenite balance | Austenitic / Duplex stainless steel bars | Not applicable for aluminum or titanium |

| 7 | Thickness Test of Coatings | Measures coating or anodized layer thickness | Plated, coated, or anodized bars | For special surface-treated bars only |

| 8 | In-situ Simulated Corrosion Test | Evaluates corrosion resistance per NACE or custom spec | Stainless steel, nickel alloy bars | Used in marine or chemical projects |

| 9 | Ultrasonic Flaw Detection (UT) | Detects internal defects and inclusions in solid bars | All metallic solid bars | Replaces wall-thickness test (for tubes only) |

| Chemical Composition Analysis: |

At SAKY STEEL, we ensure every batch of material meets the international standards through comprehensive chemical composition analysis. Our advanced laboratory is equipped with state-of-the-art instruments, including Optical Emission Spectrometer (OES), Positive Material Identification (PMI) device, Inductively Coupled Plasma Spectrometer (ICP), and X-Ray Fluorescence (XRF) analyzer.

| Method (Abbreviation) | Full English Name / Description | Typical Purpose |

|---|---|---|

| OES | Optical Emission Spectrometric Analysis | Rapid alloy composition testing |

| PMI | Positive Material Identification | On-site material grade verification |

| ICP | Inductively Coupled Plasma Spectrometric | Precise trace element analysis |

| XRF | X-Radial Fluorescence Spectrometric | Multi-element analysis for metal and alloy samples |

| Carbon & Sulfur Analyse | Carbon and Sulfur Analyzer | Determination of C and S content in steels |

| N/O/H Analyse | Nitrogen, Oxygen, and Hydrogen Analyzer | Gas element detection in metals |

| Chemical Titration | Classical Wet Chemistry Method | Standard chemical verification |

| Spectrophotometer | UV-Visible Spectrophotometric Analysis | Trace element colorimetric testing |

| FAAS | Flame Atomic Absorption Spectroscopy | Quantitative element measurement |

| GC | Gas Chromatography | Separation and analysis of gases or volatile compounds |

| IC | Ion Chromatography | Analysis of anions and cations in solutions |

| GD-MS | Glow Discharge Mass Spectrometry | Depth profiling and surface analysis |

| TOC Analyzer | Total Organic Carbon Analyzer | Organic content testing |

| IR Spectrometer | Infrared Spectrometry | Molecular structure and compound identification |

| Mechanical Performance Testing: |

At SAKY STEEL, we conduct a full range of mechanical performance tests to ensure the strength, toughness, and durability of every stainless steel, alloy steel, and nickel alloy product we deliver.We perform comprehensive tests such as tensile strength, yield strength, elongation, hardness (Brinell, Rockwell, Vickers, Leeb), bending, impact toughness, fatigue, and fracture toughness (KIC and CTOD). These tests precisely measure the mechanical behavior of materials under various loads and environments, ensuring full compliance with ASTM, EN, GB, and ISO standards.

| Test Item | Full Name / Description |

|---|---|

| Brinell / Rockwell / Vickers hardness test | Hardness measurement for different metal types |

| Knoop / Leeb / Webster hardness test | Portable and micro hardness testing |

| Shore / Mohs / Pencil hardness test | Surface hardness assessment |

| Nano indentation test | Micro/nano mechanical property analysis |

| Room / high temperature tensile test | Tensile strength testing at ambient or elevated temperatures |

| Elastic modulus / Poisson’s ratio test | Elastic deformation characteristics |

| Tensile strain hardening exponent (n) test | Material strain-hardening behavior |

| Plastic strain ratio (r) test | Plastic deformation property |

| Bend test | Ductility and formability testing |

| Reverse bend test | Fatigue and flexibility assessment |

| Flaring / flanging / flattening test | Tube and pipe forming performance evaluation |

| Low / room temperature impact test | Impact toughness testing under various conditions |

| Temper brittleness assessment | Evaluation of temper embrittlement |

| Fracture toughness test (KIC test) | Crack resistance under stress |

| Shear test | Shear strength measurement |

| Fatigue test | Durability under cyclic loading |

| Endurance creep test | Long-term deformation resistance |

| Crack Tip Opening Displacement (CTOD) test | Fracture mechanics and crack propagation analysis |

| Non-standard mechanical test | Customized testing based on client requirements |

| Applications of 309, 309S, and 309H Round Bars: |

309, 309S, and 309H stainless steel bars are widely used in high-temperature and corrosive service environments where strength, oxidation resistance, and structural stability are critical. These grades perform exceptionally well in both continuous and intermittent heating conditions, making them ideal for thermal process equipment and heavy industrial use.

Typical applications include:

-

Furnace parts, burner nozzles, and heat treatment baskets

-

Boiler tubes, superheater supports, and heat exchanger components

-

Chemical processing and petrochemical equipment

-

Kiln liners, retorts, and radiant tubes

-

Exhaust systems and flue gas components in power generation

-

Expansion joints, combustion chambers, and refractory anchors

-

Food processing and thermal oxidation systems

With their excellent combination of strength, corrosion resistance, and heat stability, SakySteel 309 / 309S / 309H stainless steel bars ensure long service life and reliable performance in demanding industrial environments.

| FAQ |

Q1: What is the main difference between 309, 309S, and 309H?

309S has lower carbon for better weldability, while 309H has higher carbon for improved high-temperature strength.

Q2: Can these grades be hardened by heat treatment?

No. 309, 309S, and 309H are austenitic steels; they can only be strengthened by cold working.

Q3: What is the service temperature range?

They resist oxidation and scaling up to about 1100°C (2010°F).

Q4: What are common applications?

Furnaces, boilers, heat exchangers, exhaust systems, and chemical processing equipment.

Q5: Which surface finishes are available?

Hot-rolled, cold-drawn, polished, and bright bars supplied by SakySteel.

| Why Choose SAKYSTEEL : |

Reliable Quality – Our stainless steel bars, pipes, coils, and flanges are manufactured to meet international standards such as ASTM, AISI, EN, and JIS.

Strict Inspection – Every product undergoes ultrasonic testing, chemical analysis, and dimensional control to ensure high performance and traceability.

Strong Stock & Fast Delivery – We maintain regular inventory of key products to support urgent orders and global shipping.

Customized Solutions – From heat treatment to surface finish, SAKYSTEEL offers tailor-made options to match your exact requirements.

Professional Team – With years of export experience, our sales and technical support team ensures smooth communication, quick quotations, and full documentation service.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Testg

| SAKY STEEL’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,