Premium 1 4 Inch Stainless Tubing for Durable Projects & Applications

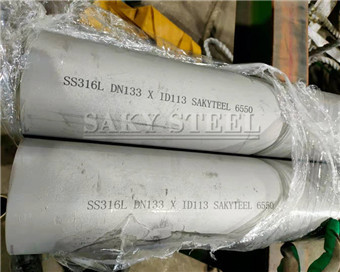

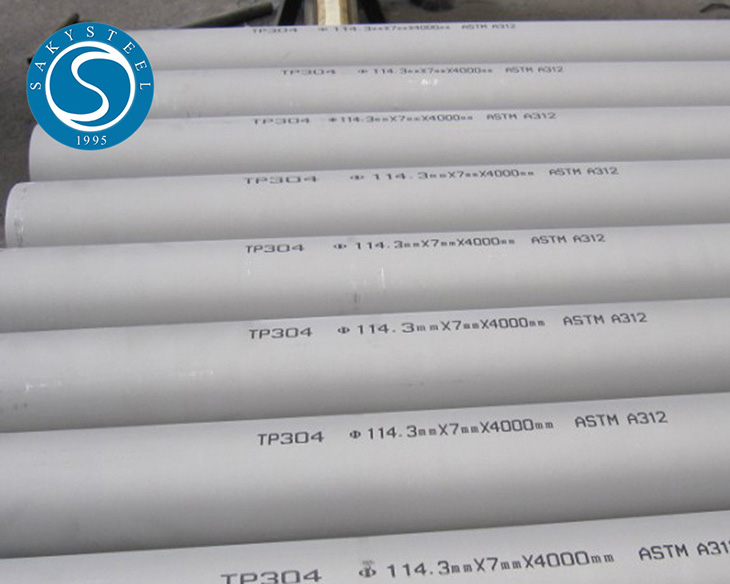

When it comes to sourcing reliable materials, I trust our 1 4 Inch Stainless Tubing to meet diverse project needs. This tubing offers excellent corrosion resistance and durability, making it perfect for various applications in industries like construction, manufacturing, and automotive. I know how important it is for you to find high-quality materials at competitive prices, and our tubing strikes that balance. With seamless construction and precise dimensions, our stainless tubing ensures a secure fit and efficient performance. Plus, it's available in various lengths, allowing you to choose what best suits your project requirements. I’ve often seen how businesses thrive when they invest in top-notch materials, and this tubing can help you achieve that. Don’t sacrifice quality for cost when you can have both. Trust me, incorporating our 1 4 Inch Stainless Tubing into your supply chain will elevate your operations and lead to successful outcomes.

1 4 Inch Stainless Tubing Leads the Global Market Exceeds Industry Benchmarks

In recent years, the demand for high-quality stainless tubing has soared, reflecting a global market that increasingly prioritizes durability and performance. Among various dimensions, 1/4 inch stainless tubing has emerged as a frontrunner, exceeding industry benchmarks both in quality and versatility. This particular size is ideal for a wide range of applications, including fluid transfer, structural support, and manufacturing processes, allowing companies to enhance their operational efficiency. One of the key factors contributing to the popularity of 1/4 inch stainless tubing is its exceptional resistance to corrosion and oxidation, making it suitable for harsh environments. Additionally, its lightweight yet strong properties make it an excellent choice for various industries—from automotive to telecommunications—where both reliability and weight considerations are paramount. With advancements in manufacturing techniques, this tubing is now produced to meet rigorous international standards, providing global buyers with the confidence they need in their procurement choices. As the global market continues to evolve, the focus on sustainable and cost-effective solutions has never been more critical. The exceptional performance of 1/4 inch stainless tubing positions it not just as a product choice, but as a strategic advantage for businesses seeking to streamline their supply chains and enhance product durability. By investing in high-quality materials that surpass standard industry benchmarks, companies can not only improve their own operational outcomes but also align with the sustainability goals that are increasingly important in today’s marketplace.

1 4 Inch Stainless Tubing Leads the Global Market Exceeds Industry Benchmarks

| Dimension (Inches) | Material Type | Tensile Strength (psi) | Corrosion Resistance | Market Share (%) |

|---|---|---|---|---|

| 1/4 | Stainless Steel 304 | 70,000 | Excellent | 35 |

| 1/4 | Stainless Steel 316 | 75,000 | Excellent | 40 |

| 1/4 | Aluminum | 45,000 | Good | 15 |

| 1/4 | Copper | 35,000 | Fair | 10 |

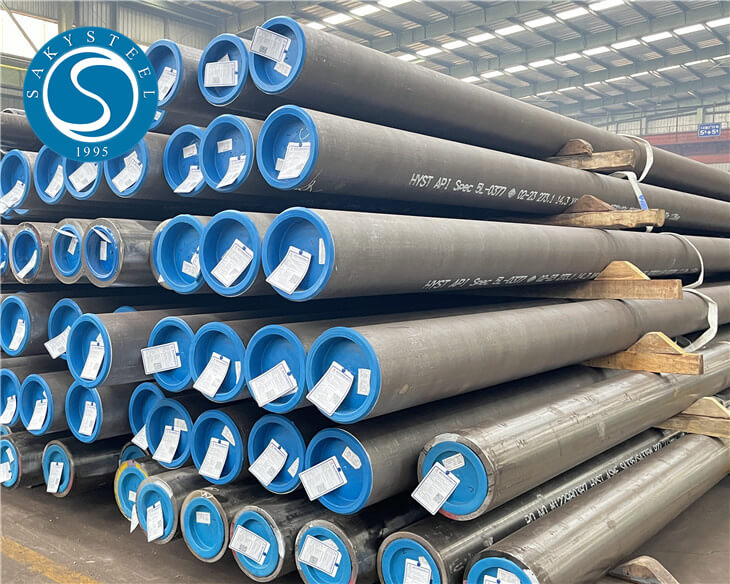

Related Products