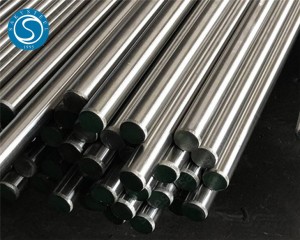

1.4749 Heat Resisting Steel Bar

Short Description:

1.4749 heat resisting ferritic steel bar offers excellent oxidation resistance and stability at elevated temperatures. Saky Steel supplies DIN 1.4749 / X10CrAlSi18 bars with high strength, superior thermal resistance, and fast delivery worldwide.

1.4749 heat resisting ferritic steel bar (X10CrAlSi18) is a chromium-aluminum alloyed steel with excellent oxidation resistance and thermal stability up to 1000°C. It is ideal for components exposed to high-temperature gases and oxidation environments.

| Grade | 1.4749 |

| Length | 1000 mm – 6000 mm or as requested |

| Diameter Range | 10 mm – 200 mm (custom available) |

| Technology | Hot Rolled / Forged / Cold Drawn |

| Surface Finish | Bright, Peeled, Polished, Turned, Pickled |

| Form | Round, Square, Flat, Hexagonal |

| Chemical Composition 1.4749 steel bar: |

| C | Cr | Mn | Si | S | P | N |

| 0.15-0.20 | 26.0-29.0 | 1.0 | 1.0 | 0.015 | 0.040 | 0.15-0.25 |

| Mechanical Properties Of 1.4749 Austenitic Steel: |

| Name | Number | Heat condition | Hardness HB max | Proof strength | Tensile strength |

| X18CrN28 | 1.4749 | +A annealed | 212 | 280 | 500-700 |

| Applications of 1.4872 Heat Resisting Austenitic Steel |

-

Industrial Furnaces and Kilns:

Used for furnace parts, supports, and heat treatment fixtures due to excellent oxidation and scaling resistance at temperatures up to 1000°C. -

Exhaust and Burner Components:

Ideal for exhaust manifolds, burner tubes, and combustion chambers operating under continuous high-temperature conditions. -

Thermal Processing Equipment:

Applied in ovens, dryers, and heat exchangers where long-term exposure to heat and oxidation occurs. -

Petrochemical and Metallurgical Plants:

Suitable for heater tubes, catalytic reformer parts, and other components requiring resistance to carburization and thermal fatigue. -

Incinerators and Power Equipment:

Performs reliably in waste incinerators, boiler parts, and other systems exposed to cyclic heating and corrosive gases.

| FAQ |

Q1: What is 1.4749 ferritic steel used for?

A1: It’s mainly used in furnace parts, heat exchangers, and exhaust systems operating up to 1000°C due to its high oxidation resistance.

Q2: How does 1.4749 compare to 1.4762 or 1.4841?

A2: 1.4749 offers better oxidation resistance than 1.4762 and lower thermal expansion than 1.4841, making it suitable for stable, high-temperature applications.

Q3: Is 1.4749 magnetic?

A3: Yes, as a ferritic steel, it remains magnetic even at elevated temperatures.

| Why Choose SAKYSTEEL : |

Reliable Quality – Our stainless steel bars, pipes, coils, and flanges are manufactured to meet international standards such as ASTM, AISI, EN, and JIS.

Strict Inspection – Every product undergoes ultrasonic testing, chemical analysis, and dimensional control to ensure high performance and traceability.

Strong Stock & Fast Delivery – We maintain regular inventory of key products to support urgent orders and global shipping.

Customized Solutions – From heat treatment to surface finish, SAKYSTEEL offers tailor-made options to match your exact requirements.

Professional Team – With years of export experience, our sales and technical support team ensures smooth communication, quick quotations, and full documentation service.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

| SAKY STEEL’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,