1.2713 Tool Steel

Short Description:

DIN 1.2713 tool steel is a high-toughness alloy mold steel widely used for hot work dies, forging dies and plastic molds.

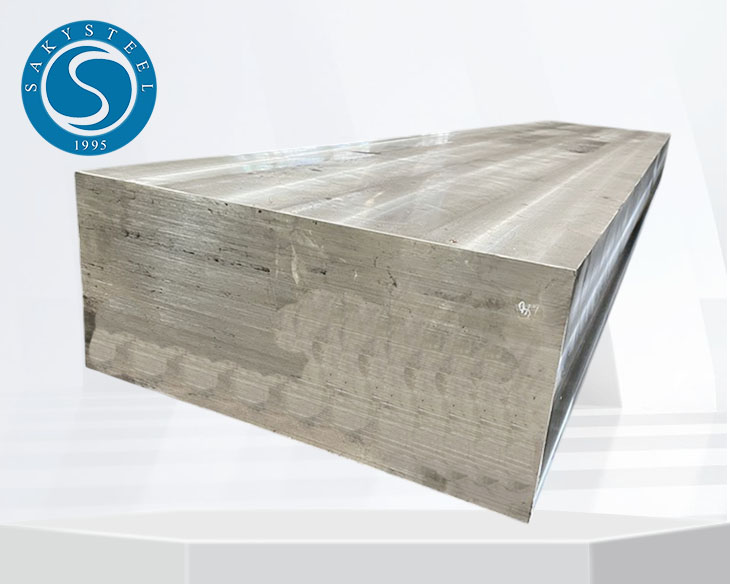

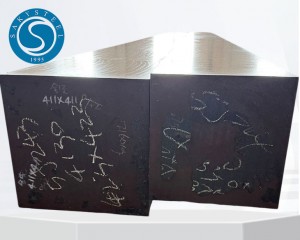

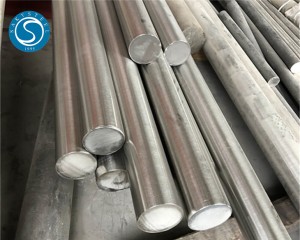

DIN 1.2713 tool steel is a nickel-chromium-molybdenum alloy hot work mold steel known for its excellent toughness, high strength, and good hardenability. It is commonly supplied in forged bars or blocks and widely used in heavy-duty forging dies and hot work tooling applications.

| Specifications of 1.713 Tool Steel: |

| Grade | 1.2713 |

| Thickness tolerance | -0 to +0.1mm |

| Flatness | 0.01/100mm |

| Technology | Hot Work / Forged / Cold Drawn |

| Surface roughness | Ra ≤1.6 or Rz ≤6.3 |

| Physical Properties of 1.713 Tool Steel: |

| Property | Value | Unit | Condition |

|---|---|---|---|

| Modulus of Elasticity | 210 | GPa | Ambient |

| Density | 8.00 | g/cm³ | Ambient |

| Service Hardness | 1000 | N/mm² | Ready for Use |

| Chemical Composition 1.2713 steel rod: |

| C | Si | Mn | Ni | Cr | V | W |

| 0.50 | 1.35 | 0.70 | 13.0 | 13.0 | 0.65 | 2.15 |

| Applications: |

DIN 1.2713 tool steel is widely used for heavy-duty tooling applications requiring high toughness, excellent strength, and good hardenability. It is particularly suitable for large cross-section components where uniform mechanical properties and resistance to impact loading are essential.

Typical applications include hot forging dies, die holders, hot extrusion tools, heavy press tools, and large mold blocks. Due to its outstanding toughness and reliable performance after heat treatment, DIN 1.2713 is also commonly used for plastic mold bases and structural mold components subjected to high mechanical stress.

| Tool Steel UT Test: |

1.2713 hot work tool steel is subjected to ultrasonic testing (UT) to ensure internal soundness and reliability for critical applications. The UT test detects internal defects such as inclusions, porosity, shrinkage cavities, or cracks that may compromise the steel’s performance under high thermal and mechanical stresses. Inspection is carried out in accordance with international standards , using calibrated probes to evaluate the entire cross-section. Only defect-free material with homogeneous internal structure is accepted, guaranteeing high toughness, excellent thermal fatigue resistance, and consistent quality for die casting, extrusion dies, and hot forging tools.

|

|

| Suface Option |

1.Black Surface – As-rolled or forged finish with oxide scale.

2.Ground Finish – Bright appearance with a slightly rough texture; not precision ground.

3.Machined Plate Finish – Bright and accurate dimensions; minor turning marks may be visible.

4.Peeled/Turned Finish – Bright with precise sizing; slight turning marks remain.

5.Polished Finish – Highly bright with precise dimensions; free from turning marks.

| FAQ |

Q1: What is DIN 1.2713 tool steel used for?

A: It is mainly used for hot work dies, forging tools, and large mold components requiring high toughness.

Q2: Can 1.2713 tool steel be heat treated?

A: Yes, DIN 1.2713 can be quenched and tempered to achieve uniform hardness and excellent mechanical properties.

| Why Choose SAKYSTEEL : |

Reliable Quality – Our stainless steel bars, pipes, coils, and flanges are manufactured to meet international standards such as ASTM, AISI, EN, and JIS.

Strict Inspection – Every product undergoes ultrasonic testing, chemical analysis, and dimensional control to ensure high performance and traceability.

Strong Stock & Fast Delivery – We maintain regular inventory of key products to support urgent orders and global shipping.

Customized Solutions – From heat treatment to surface finish, SAKYSTEEL offers tailor-made options to match your exact requirements.

Professional Team – With years of export experience, our sales and technical support team ensures smooth communication, quick quotations, and full documentation service.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

| Custom Processing Capabilities: |

1.Hardening and tempering process

2.Vacuum heat treatment

3.Bright polished surface finish

4.Bright milled surface finish

5.CNC precision machining

6.Deep hole drilling

7.Cutting into smaller sections

8.Machining to near-net mold shape

We welcome your price inquiries based on your drawings.

| SAKY STEEL’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,