ER385 Stainless Steel Welding Rod

Short Description:

ER385 is a type of welding filler metal, specifically a stainless steel electrode. The “ER” stands for “Electrode or Rod,” and the “385″ indicates the chemical composition and characteristics of the filler metal. In this case, ER385 is designed for welding austenitic stainless steels.

ER385 Welding Rod:

Austenitic stainless steels, such as Type 904L, contain high levels of chromium, nickel, and molybdenum, making them highly corrosion-resistant and suitable for use in harsh environments. ER385 welding rods are commonly used in applications where corrosion resistance is a critical factor, such as in the chemical, petrochemical, and marine industries.ER385 welding rods are suitable for various welding processes, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW or TIG), and gas metal arc welding (GMAW or MIG).

Specifications Of ER385 Welding Wire:

| Grade | ER304 ER308L ER309L,ER385 etc. |

| Standard | AWS A5.9 |

| Surface | Bright, Cloudy,Plain,Black |

| Diameter | MIG – 0.8 to 1.6 mm,TIG – 1 to 5.5 mm,Core wire – 1.6 to 6.0 |

| Application | It is commonly used in the production and preparation of towers, tanks, pipelines and storage and transportation containers for various strong acids. |

Equivalent of Stainless Steel ER385 Wire:

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| ER-385 | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Chemical Composition SUS 904L Welding Wire:

According to standard AWS A5.9

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo | Cu |

| ER385(904L) | 0.025 | 1.0-2.5 | 0.02 | 0.03 | 0.5 | 19.5-21.5 | 24.0-36.0 | 4.2-5.2 | 1.2-2.0 |

1.4539 Welding Rod Mechanical properties:

| Grade | Tensile Strength ksi[MPa] | Elongation % |

| ER385 | 75[520] | 30 |

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

Welding current parameters: DCEP (DC+)

| Wire diameter specification (mm) | 1.2 | 1.6 |

| Voltage (V) | 22-34 | 25-38 |

| Current (A) | 120-260 | 200-300 |

| Dry elongation (mm) | 15-20 | 18-25 |

| Gas flow | 20-25 | 20-25 |

What are the characteristics of ER385 Welding Wire?

1. Excellent corrosion resistance, can resist uniform corrosion of sulfuric acid and phosphoric acid, resist corrosion of acetic acid at any temperature and concentration under normal pressure, and can effectively solve pitting corrosion, pitting corrosion, crevice corrosion, stress corrosion and other problems of halides.

2. The arc is soft and stable, with less spatter, beautiful shape, good slag removal, stable wire feeding, and excellent welding process performance.

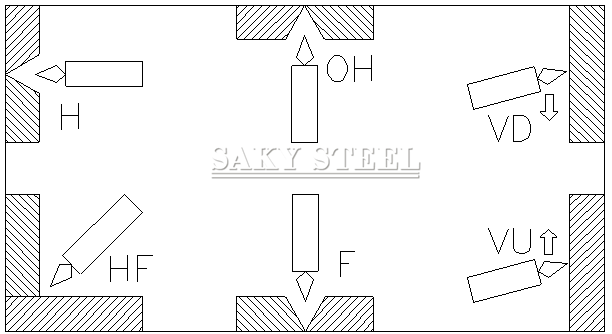

Welding positions and important items:

1. Use windproof barriers when welding in windy places to avoid blowholes caused by strong winds.

2. The temperature between passes is controlled at 16-100℃.

3. Moisture, rust stains and oil stains on the surface of the base metal must be fully removed before welding.

4. Use CO2 gas for welding, the purity must be greater than 99.8%, and the gas flow should be controlled at 20-25L/min.

5. The dry extension length of the welding wire should be controlled within the range of 15-25mm.

6. After unpacking the welding wire, please note: take moisture-proof measures, use it up as soon as possible, and do not leave unused welding wire exposed in the air for a long time.

Our Clients

Stainless Steel I Beams Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,