-

Hardness is one of the most important mechanical properties of steel, affecting its strength, wear resistance, and performance in different applications. For engineers, manufacturers, and quality inspectors, hardness testing is a standard procedure in material selection and quality control. Howev...Read more »

-

Stainless steel is one of the most widely used materials in industries such as construction, manufacturing, food processing, medical equipment, and marine engineering. Its durability, corrosion resistance, and aesthetic appeal make it the preferred choice for countless applications. However, due ...Read more »

-

Precipitation hardening stainless steel, also known as PH stainless steel, is a special category of stainless steel that achieves high strength through a unique heat treatment process called precipitation hardening. This process improves mechanical properties without compromising corrosion resist...Read more »

-

Heating is one of the most important processes in metalworking and metallurgy. From forging and welding to heat treatment and annealing, applying heat to metal changes its internal structure and therefore its mechanical and physical properties. These changes can be beneficial or detrimental depen...Read more »

-

Tool steel is a category of carbon and alloy steels designed specifically for manufacturing tools, dies, and molds. These steels are characterized by their high hardness, wear resistance, and ability to retain a cutting edge at elevated temperatures. They are essential in industries ranging from ...Read more »

-

In metal fabrication, creating holes and cutouts in metal sheets, plates, and profiles is a fundamental process. Three common methods used for this purpose are hole punching, notching, and drilling. While these processes may seem similar, they differ significantly in terms of technique, equipment...Read more »

-

When it comes to high-performance steels for knives, cutting tools, bearings, and precision components, 440C stainless steel and D2 tool steel are two popular choices. Both materials are known for their hardness, wear resistance, and durability, but they differ in composition, corrosion resistanc...Read more »

-

Steel is one of the most widely used materials in the world, valued for its strength, durability, and versatility. However, the manufacturing process used to produce steel components plays a critical role in determining their properties and performance. Two of the most common production methods a...Read more »

-

When it comes to selecting the right steel for knives, cutting tools, and wear-resistant components, two popular options are D2 tool steel and 8Cr13MoV stainless steel. Both have distinct chemical compositions, mechanical properties, and advantages, making them suitable for different applications...Read more »

-

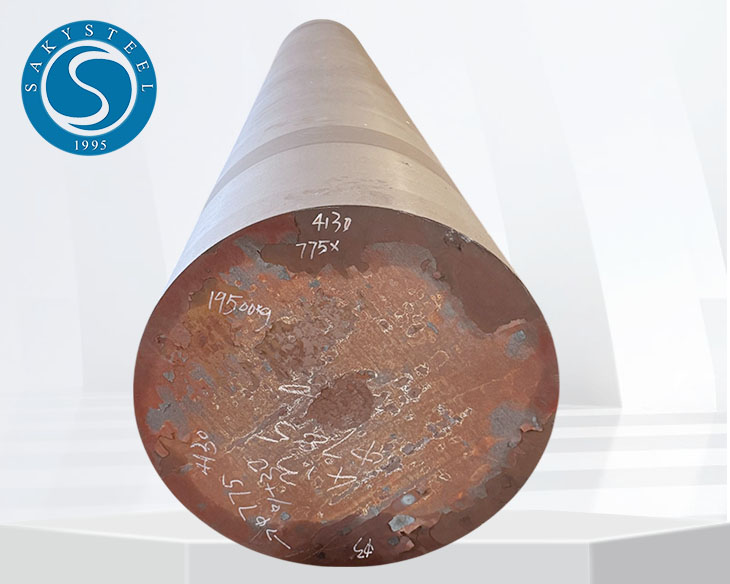

4130 steel, also known as Chromoly steel (chromium-molybdenum steel), is a low-alloy steel that has become a popular material in aerospace, automotive, motorsports, oil and gas, and manufacturing industries. Known for its combination of strength, toughness, weldability, and machinability, 4130 st...Read more »

-

In the world of metallurgy and material science, hardness is one of the most critical properties used to evaluate the quality and performance of a material. Hardness tests measure a material’s resistance to deformation, scratching, or indentation. Among the many hardness testing methods, the Brin...Read more »

-

Heat treatment is a critical industrial process used to alter the physical and mechanical properties of metals and alloys without changing their shapes. By carefully controlling heating and cooling cycles, manufacturers can improve strength, hardness, ductility, and wear resistance to meet specif...Read more »

-

Forging is one of the most important metalworking processes used to create high-strength, high-performance components. It involves shaping metal through compressive forces, which improves mechanical properties, refines grain structure, and enhances durability. Among forging methods, hot forging a...Read more »

-

Forging is a manufacturing process that shapes metal through compressive forces, producing components with exceptional strength and durability. Because forgings are often used in critical applications such as aerospace, automotive, oil and gas, and power generation, ensuring their quality is esse...Read more »

-

Forging is one of the oldest and most reliable methods of shaping metal, used for producing components with exceptional strength, toughness, and reliability. In industries such as automotive, aerospace, energy, and heavy machinery, forged parts are essential for critical applications where failur...Read more »