-

Hydrogen embrittlement is a critical concern in the production and post-treatment of forgings, especially those made of high-strength steels, stainless steels, and titanium alloys. The presence of hydrogen atoms trapped in the metal structure can lead to cracking, reduced ductility, and unexpecte...Read more »

-

Stainless steel forgings are widely used in industries such as petrochemical, aerospace, automotive, construction, and food processing. These components are valued for their corrosion resistance, strength, and durability. However, to achieve optimal performance, stainless steel forgings often req...Read more »

-

Forging is a fundamental metal forming process that plays a critical role in manufacturing strong and durable components across various industries. From automotive crankshafts and aerospace brackets to construction fasteners and oilfield tools, forged parts are known for their excellent mechanica...Read more »

-

When it comes to metalworking and manufacturing, casting and forging are two foundational processes used to shape metal into functional components. Both methods have their advantages and disadvantages and are suited for different applications, environments, and performance expectations. Understan...Read more »

-

Forging is a widely adopted manufacturing process used to shape metals under high pressure. It is known for producing strong, reliable, and defect-resistant components that are essential in high-performance industries such as automotive, aerospace, oil and gas, construction, and machinery. Howeve...Read more »

-

Forging is one of the oldest and most trusted metalworking processes, used to shape metal using compressive forces. It enhances mechanical properties, refines grain structures, and eliminates defects, making forged components ideal for demanding applications such as aerospace, automotive, power g...Read more »

-

Forging and forming are two of the most essential manufacturing processes in the production of metal components. These methods are used to shape metal by applying heat and pressure, resulting in stronger, more durable parts. Forging and forming are widely used in industries such as aerospace, aut...Read more »

-

Forging is one of the oldest and most essential methods of metalworking, used to shape and mold metal into desired forms through the application of pressure, heat, or both. It is a crucial process in manufacturing industries such as aerospace, automotive, construction, and heavy machinery, where ...Read more »

-

Wire rope is an essential component in many industries, from construction and mining to marine and aerospace. Known for its strength, flexibility, and durability, wire rope is often coated to enhance its performance and protect it from environmental factors such as corrosion, wear, and abrasion. ...Read more »

-

Stainless steel is one of the most widely used materials in various industries due to its excellent corrosion resistance, durability, and versatility. Among the different types of stainless steel, 304 and 316 are two of the most commonly used alloys. While both have remarkable properties, one of ...Read more »

-

1.2343 tool steel, also known as H11, is a high-performance steel alloy that offers exceptional properties for use in a variety of demanding applications. Its unique combination of heat resistance, strength, and toughness makes it an ideal choice for industries that require high-precision tools a...Read more »

-

In industries where safety, durability, and quality are paramount, using genuine steel is not just a matter of preference—it’s a necessity. Unfortunately, counterfeit and substandard steel products are increasingly entering the market, especially in construction, manufacturing, and engineering se...Read more »

-

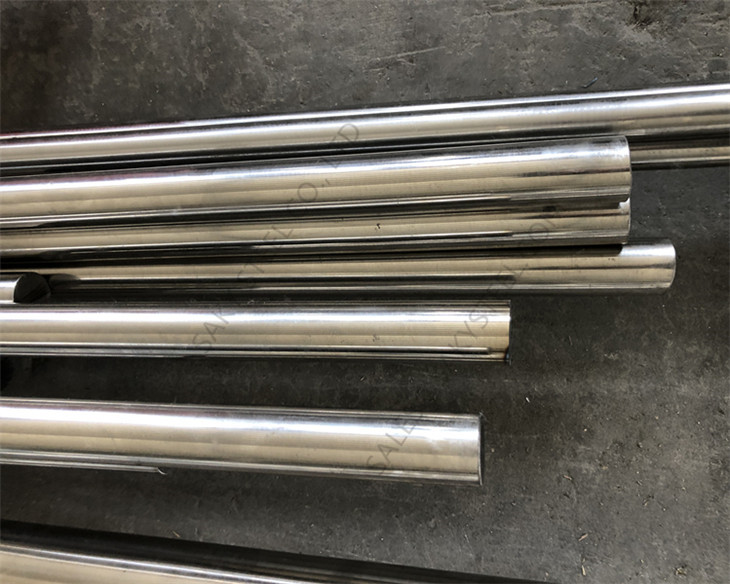

Pipes are fundamental to industries like oil and gas, construction, automotive, and machinery manufacturing. Among the various types, hot rolled seamless pipe stands out for its strength, uniformity, and ability to withstand high pressure and temperature. Unlike welded pipes, seamless pipes have ...Read more »

-

When it comes to selecting the right type of steel for your project, the decision often boils down to carbon steel vs. stainless steel. Both materials are widely used across industries—from construction and manufacturing to automotive and consumer goods. While they may appear similar, carbon stee...Read more »

-

Duplex stainless steel has gained increasing popularity across various industries due to its exceptional combination of strength, corrosion resistance, and cost-effectiveness. Among the most widely used grades in this family is Duplex Steel S31803, also known as UNS S31803 or 2205 duplex stainles...Read more »