Mig Stainless Steel Wire: Expert Tips for Choosing the Best Quality

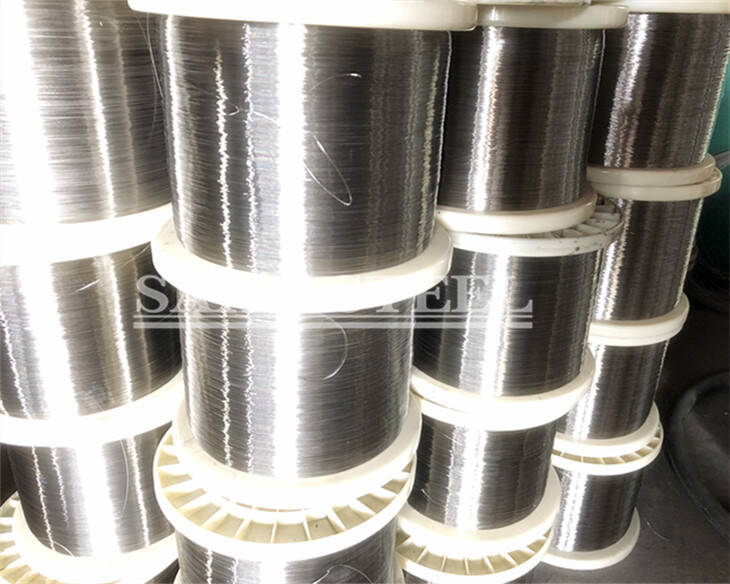

When I set out to find reliable supplies for my projects, the quality of materials is always my top priority. That's why I trust Mig Stainless Steel Wire for all my welding needs. This wire offers outstanding durability and excellent resistance to corrosion, making it perfect for both indoor and outdoor applications. Whether I'm working on automotive manufacturing or general fabrication, this wire never lets me down. I appreciate how efficiently it feeds through my welding machine, allowing me to maintain a smooth welding process. Plus, the versatility is impressive; it performs well with a variety of materials. If you’re looking to enhance the quality and longevity of your welds, Mig Stainless Steel Wire is definitely a smart choice. It’s backed by a company known for its commitment to excellence, ensuring that I consistently get high-performance results. With this wire in your toolkit, you can trust that your projects will shine with precision and strength.

Mig Stainless Steel Wire Sets the Industry Standard Where Innovation Meets 2025

In the ever-evolving landscape of industrial materials, the demand for high-quality stainless steel wire is continuously on the rise. As the manufacturing sector advances towards 2025, our dedication to innovation positions us at the forefront of this pivotal transformation. The introduction of cutting-edge manufacturing techniques and rigorous quality control measures allows us to deliver stainless steel wire that not only meets but often exceeds industry standards. Our stainless steel wire is designed with versatility in mind, catering to a diverse range of applications — from automotive to aerospace, and construction to art. With an unwavering commitment to excellence, we ensure that our products maintain superior corrosion resistance, tensile strength, and performance under varied conditions. This commitment is more than just a promise; it is the cornerstones of our operational philosophy, enabling us to build lasting partnerships with global purchasers who prioritize quality and reliability. As we approach 2025, the fusion of innovation and industry standards becomes crucial for businesses looking to remain competitive. By choosing our stainless steel wire products, global buyers can leverage advanced material solutions designed to optimize their operations, reduce waste, and foster sustainability. We invite discerning procurement managers from around the world to explore how our innovative wire solutions can lead their businesses into a new era of efficiency and performance.

Mig Stainless Steel Wire Sets the Industry Standard Where Innovation Meets 2025

| Wire Diameter (mm) | Tensile Strength (MPa) | Applications | Melting Point (°C) |

|---|---|---|---|

| 0.8 | 620 | Automotive Components | 1400 |

| 1.0 | 650 | Construction | 1400 |

| 1.2 | 670 | Marine Applications | 1400 |

| 1.6 | 700 | Manufacturing | 1400 |

| 2.0 | 750 | Heavy Equipment | 1400 |

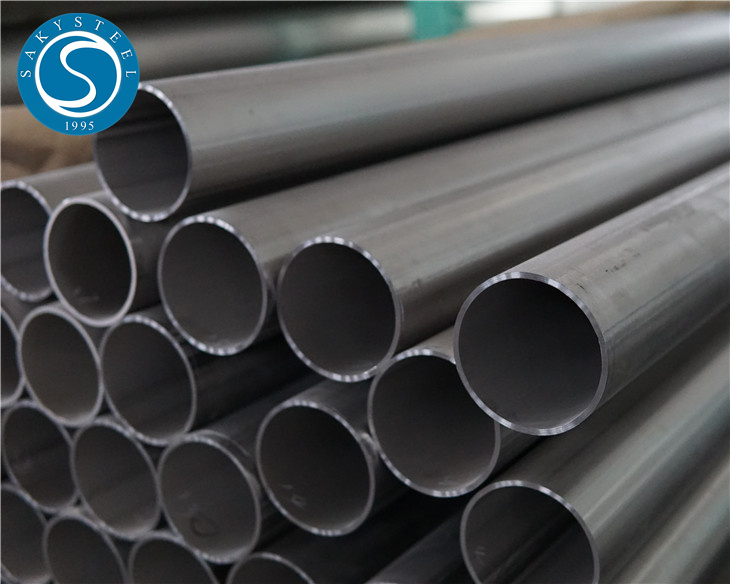

Related Products