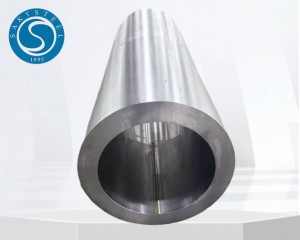

Stainless Steel Needle Tube

Short Description:

Stainless steel needle tube is a high-precision medical-grade tubing known for its smooth surface, excellent corrosion resistance, and dimensional accuracy. It is widely used in medical instruments, injection systems, and laboratory equipment where strength, cleanliness, and biocompatibility are essential.

Stainless steel needle tube is a precision medical component made from high-quality stainless steel, designed for exceptional strength, corrosion resistance, and dimensional accuracy. It features a smooth inner surface for consistent fluid flow and a polished outer surface for easy insertion and reduced friction. Widely used in medical, laboratory, and aesthetic instruments, stainless steel needle tubes ensure durability, biocompatibility, and safety in various precision applications.

| Specifications of stainless steel capillary tube: |

| Standard: | GB/T12771-2008 ASTM A312/A312M,ASTM A213/213A |

| Material: |

201 304 316 317 321 347 |

| OD: | 0.6 — 36mm |

| Thickness: | 0.12 — 1.8mm |

| Tolerance | 0.02 — 0.03mm |

| Surface : | Mill Bright |

| Application | Injection tube for medical equipment industry, medical industrial tube; electric heating tube, heating tube, electric heating tube |

| Features & Advantages of Stainless Steel Needle Tube: |

-

High Precision and Smooth Finish – Manufactured with tight dimensional tolerances and mirror-polished inner surfaces to ensure smooth fluid flow and easy insertion.

-

Excellent Corrosion Resistance – Made from medical-grade stainless steel such as 304 or 316L, offering superior resistance to rust, oxidation, and sterilization chemicals.

-

Outstanding Mechanical Strength – Provides high tensile strength and flexibility, minimizing risk of bending or breakage during use.

-

Biocompatibility and Safety – Non-toxic and nickel-stabilized structure ensures compatibility with human tissues and medical environments.

-

Customizable Sizes and Finishes – Available in a wide range of outer diameters, wall thicknesses, and surface treatments to meet various industrial and medical requirements.

-

Clean and Burr-Free Edges – Precision cutting and deburring guarantee smooth ends, suitable for fine assembly and micro-needle applications.

-

Reliable Quality Control – Each tube is inspected for surface integrity, dimensional accuracy, and mechanical performance according to ASTM and ISO standards.

| FAQ: |

1. What is a stainless steel needle tube?

A stainless steel needle tube is a precision-drawn seamless tube made from medical-grade stainless steel, commonly used for producing cannulas, injection needles, and micro-needle assemblies. It provides excellent corrosion resistance, strength, and biocompatibility.

2. What materials are available for stainless steel needle tubes?

We supply stainless steel needle tubes in grades such as 304, 304L, 316, 316L, and 321, meeting ASTM A269, A270, and ISO standards. Custom grades are also available upon request.

3. What are the standard sizes and tolerances?

Outer diameters typically range from 0.3 mm to 25 mm with wall thicknesses from 0.05 mm to 2.0 mm. Tight tolerances and mirror-polished inner surfaces are available for medical and laboratory applications.

4. Are stainless steel needle tubes suitable for medical use?

Yes. Our needle tubes are made from medical-grade stainless steel with high cleanliness, smooth internal finish, and full traceability, making them suitable for medical devices and surgical instruments.

5. Can you supply customized cut lengths or surface finishes?

Absolutely. We can provide tubes cut to specific lengths, with polished, bright-annealed, or passivated finishes to meet different customer requirements.

| Stainless steel Needle tube Applications: |

Sakysteel capillary pipes Widely used in hardware kitchen utensils, shipbuilding, petrochemical, mechanical processing, automotive, medicine, food, electricity, energy, aerospace, architectural decoration, etc.

1. Small diameter precision stainless steel tubes for various tubes, industrial tubes and industrial applications, capillary tubes

2. Temperature measuring tube, sensor tube, thermometer tube for barbecue, thermometer tube for kitchen;

3. Outer casing, core tube, casing tube, antenna casing, wireless internet antenna tube, instrument and meter tube, mobile phone antenna for pen industry;

4 dispensing needles, straws, clock accessories, industrial electric heating tubes;

5 Medical equipment industry needles for injection, medical industrial tubes; electric heating tubes, heating tubes, electric heating tubes

6 all kinds of sweater needles

7 thin-walled tube, electric thermocouple tube, electric resistance tube, sanitary tube, sanitary tube, special stainless steel tube

8 Self-made tube Steam piping, electric heating manifold, air conditioning tube, temperature sensing tube, automotive tube.

9 solar tube, metal product tube, household appliance tube, precision tube, mechanical manufacturing tube

10 elevator pipe, sanitary ware pipe, rail transit pipe, pressure vessel pipe, building decoration pipe

11 nuclear power tubes, catering kitchen tubes, daily electrical tubes, structural tubes

12.Stainless steel medical tubing is used in products like Diaminy PDO Cog Thread 18G for face lift and various microcannulas to ensure strength, precision, and biocompatibility in aesthetic procedures.

| Why Choose Us: |

-

Professional Manufacturer – With over 20 years of experience in stainless steel tube production, SakySteel specializes in precision medical and industrial tubing with strict process control.

-

Strict Quality Assurance – Every stainless steel needle tube is produced under ASTM and ISO standards, with full traceability and 100% surface and dimensional inspection.

-

Advanced Equipment – Equipped with high-precision cold-drawing, bright-annealing, and ultrasonic testing machines to ensure excellent roundness and surface quality.

-

Customization Service – We provide tailored solutions for size, tolerance, and surface finish to meet the unique requirements of medical, laboratory, and cosmetic applications.

-

Fast Delivery and Global Supply – Strong inventory and efficient logistics allow us to deliver quickly to more than 60 countries worldwide.

-

Reliable Partner – Trusted by global customers for consistent quality, professional technical support, and long-term cooperation.

| Saky Steel’s Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Large-scale test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Flaring Testing

8. Water-Jet Test

9. Penetrant Test

10. X-ray test

11. Intergranular Corrosion Testing

12. Impact analysis

13. Eddy current examining

14. Hydrostatic analysis

15. Metallography Experimental Test

| Saky Steel’s Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,