stainless steel wire rope

Short Description:

Stainless Steel Wire Rope

Stainless steel wire rope is a strong, flexible, and corrosion-resistant cable widely used in marine, construction, rigging, lifting, and safety applications. Made from premium stainless steel materials such as 304, 316, and Duplex 2205, it provides excellent durability in harsh environments, including saltwater and chemical exposure. With various strand structures like 7x7, 7x19, and 6x36, the rope offers a perfect balance between strength and flexibility. It is available in different diameters and can be customized with swaged ends, thimbles, or turnbuckles according to customer requirements. Ideal for both structural and dynamic load-bearing uses.

Specifications Of Stainless Wire Rope:

| Grade | 304,316,321,2205,2507 etc. |

| Specifications | DIN EN 12385-4-2008, GB/T 9944-2015 |

| Diameter Range | 1.0 mm to 30.0mm. |

| Tolerance | ±0.01mm |

| Construction | 1×7, 1×19, 6×7, 6×19, 6×37, 7×7, 7×19, 7×37,etc. |

| Length | 100m / reel, 200m / reel 250m / reel, 305m / reel, 1000m / reel |

| Core | FC, SC, IWRC, PP |

| Surface | Bright |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

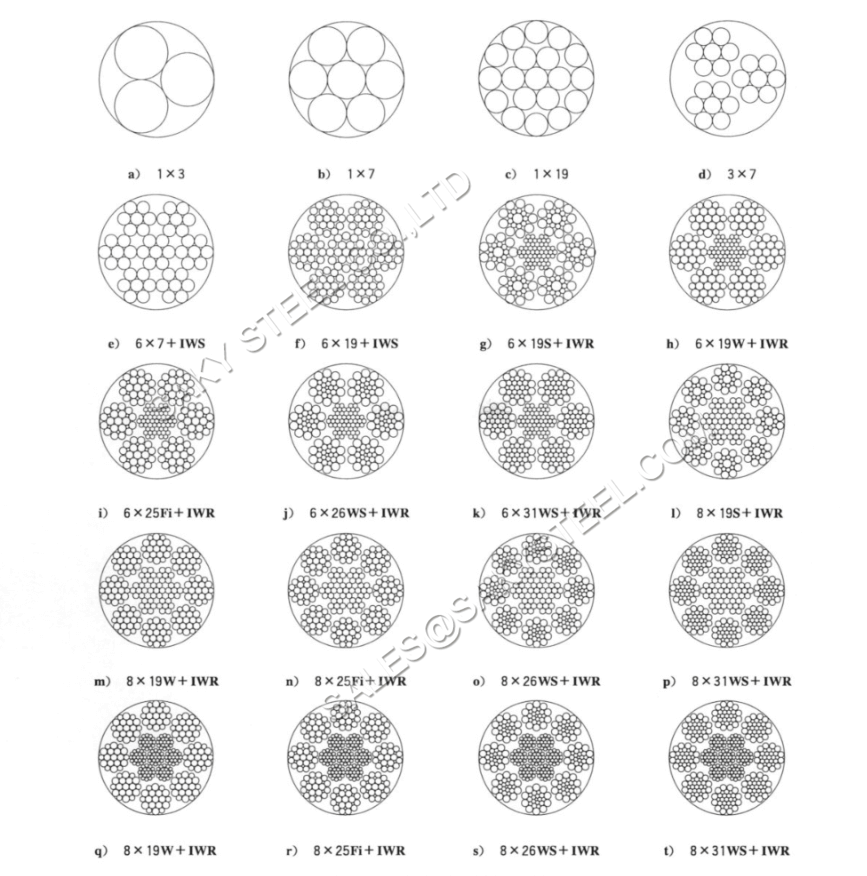

Stainless Steel Rope Construction:

This diagram illustrates various constructions of stainless steel wire rope, including single-strand types (such as 1x7 and 1x19), as well as 6-strand and 8-strand designs (like 6x19+IWS and 8x25Fi+IWR). Each structure is suited to different requirements for tensile strength, flexibility, and fatigue resistance. Core types such as IWS, IWR, and WS indicate specific internal configurations, making these ropes suitable for a wide range of applications including lifting, pulling, marine, and industrial uses.

Stock of SS Wire Rope:

| Type/mm | 304 | 316 |

| 7*7-0.8 | 50 | 60 |

| 7*7-1.0 | 40 | 50 |

| 7*7-1.2 | 32 | 42 |

| 7*7-1.5 | 26 | 36 |

| 7*7-2.0 | 22.5 | 32.5 |

| 7*7-2.5 | 20 | 30 |

| 7*7-3.0 | 18.5 | 28.5 |

| 7*7-4.0 | 18 | 28 |

| 7*7-5.0 | 17.5 | 27.5 |

| 7*7-6.0 | 17 | 27 |

| 7*7-8.0 | 17 | 27 |

| 7*19-1.5 | 68 | 78 |

| 7*19-2.0 | 37 | 47 |

| 7*19-2.5 | 33 | 43 |

| 7*19-3.0 | 24.5 | 34.5 |

| 7*19-4.0 | 21.5 | 31.5 |

| 7*19-5.0 | 18.5 | 28.5 |

| 7*19-6.0 | 18 | 28 |

| 7*19-8.0 | 17 | 27 |

| 7*19-10.0 | 16.5 | 26.5 |

| 7*19-12.0 | 16 | 26 |

Applications of stainless Steel cable:

•Marine and Offshore: Mooring lines, sailboat rigging, lifelines, and deck lashing.

•Construction: Safety barriers, suspension bridges, balustrades, and structural support cables.

•Industrial and Lifting: Crane cables, hoisting systems, winches, and pulleys.

•Transportation: Elevator ropes, cable railings, and securing cargo.

•Architecture and Design: Decorative tensioning systems, green walls, and architectural railings.

•Mining and Tunneling: Wire rope for haulage and lifting equipment in harsh underground environments.

Stainless Steel Wire Rope Advantages:

1.Corrosion Resistance

Exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking.

2.High Strength and Durability

Combines the high tensile strength of ferritic stainless steel with the toughness of austenitic stainless stee.

3.Enhanced Fatigue Resistance

Performs well under cyclic loading conditions, reducing the risk of fatigue failure in dynamic applications like cranes, winches, and hoists.

4.Excellent Temperature Performance

Maintains strength and corrosion resistance across a wide temperature range, suitable for both high-temperature industrial applications and sub-zero conditions.

5.Cost Efficiency

Offers a longer service life compared to traditional stainless steels, reducing maintenance costs and downtime in demanding environments.

6.Versatility

Suitable for use in diverse industries, including marine, oil and gas, construction, chemical processing, and renewable energy sectors.

7.Resistance to Sulfide Stress Cracking (SSC)

Ideal for use in oil and gas environments with exposure to hydrogen sulfide (H₂S).

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS, TUV ,BV 3.2 report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

Stainless Steel Wire Rope Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,