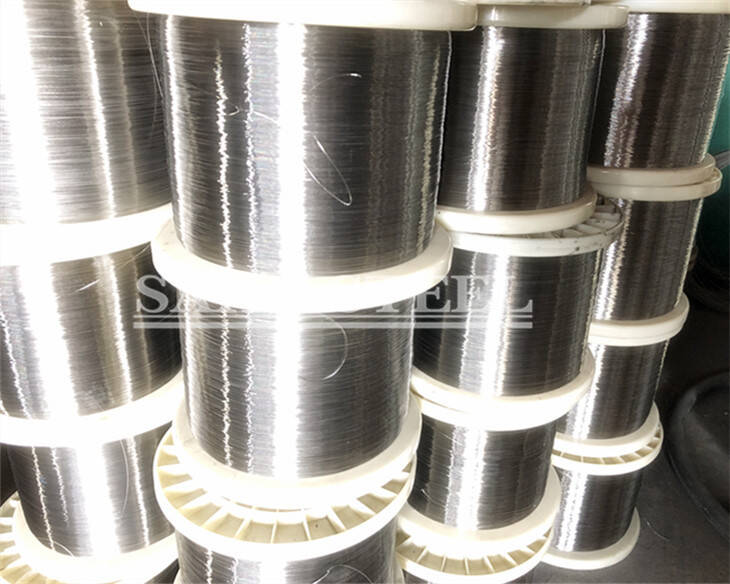

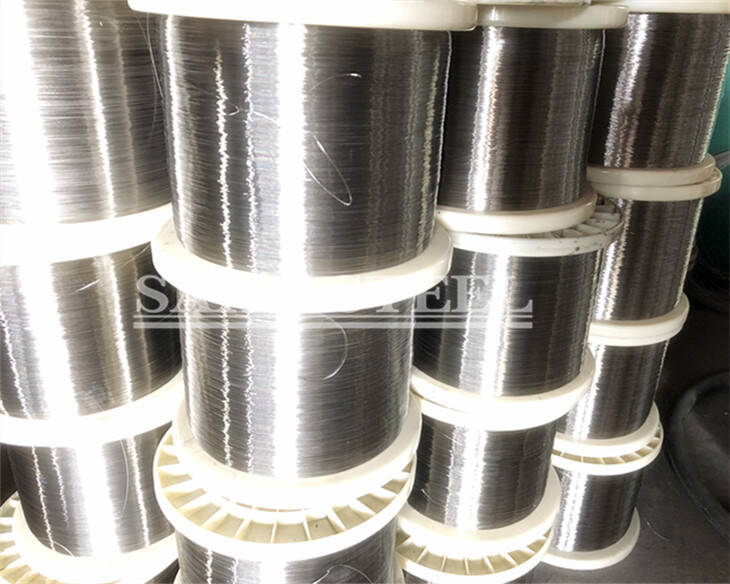

Premium 17-7 Spring Wire for Reliable Performance and Durability

When I'm sourcing high-quality materials, I always prioritize reliability and performance, which is why I turn to 17 7 Spring Wire. This premium wire offers exceptional strength and excellent corrosion resistance, making it perfect for various industrial applications. I appreciate how it retains its shape and resilience even under tension, which is crucial for projects requiring durability. Whether I'm working on automotive components or precision instruments, I know this wire delivers the consistent performance I need. Its versatility and adaptability to different environments give me peace of mind that my projects will meet the highest standards. For those interested in bulk purchasing, this wire is available in various sizes, allowing me to select the perfect fit for my specific needs. If you're after reliable materials that support optimal performance, 17 7 Spring Wire is the way to go. Can't wait to see how it elevates your projects!

17 7 Spring Wire Application Factory-Direct Excellence

When it comes to sourcing high-quality spring wire, the demand for top-notch manufacturing practices is paramount. The application of 17-7 spring wire has spread across various industries, from aerospace to automotive, due to its unique combination of strength, corrosion resistance, and excellent fatigue properties. In this and the coming era of innovation, businesses are seeking suppliers that not only ensure quality but also deliver directly from the factory, minimizing overheads and lead times. Factory-direct manufacturing not only reduces costs but also allows for greater transparency in the production process. This model empowers buyers with insights into quality controls, material sourcing, and production capabilities, ensuring that they receive a product that meets their rigorous standards. The 17-7 spring wire's versatility across different applications makes it an ideal choice for global buyers who require reliability and performance in their operations. By choosing a factory-direct approach, procurement professionals can enhance their supply chain efficiency while also benefiting from tailored solutions that meet specific application needs. Whether for medical devices, industrial machinery, or consumer products, the direct-sourcing strategy guarantees that customers receive exemplary service and top-tier materials that can withstand the demands of their respective industries. Invest in quality, improve your product reliability, and streamline your sourcing process by considering this advantageous purchasing route for spring wire applications.

17 7 Spring Wire Application Factory-Direct Excellence

| Application | Wire Diameter (mm) | Tensile Strength (N/mm²) | Material | Finish |

|---|---|---|---|---|

| Automotive Suspension | 1.5 | 1650 | Spring Steel | Oil |

| Industrial Springs | 2.0 | 1550 | Stainless Steel | Passivated |

| Medical Devices | 0.8 | 1800 | Carbon Steel | Electroplated |

| Consumer Electronics | 1.0 | 1500 | Alloy Steel | Powder Coated |

| Aerospace Components | 1.25 | 1400 | Titanium Alloy | Anodized |

Related Products