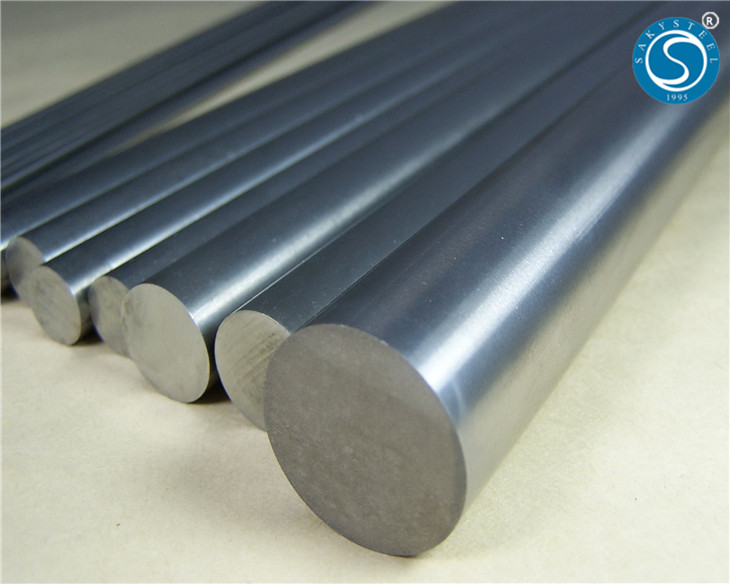

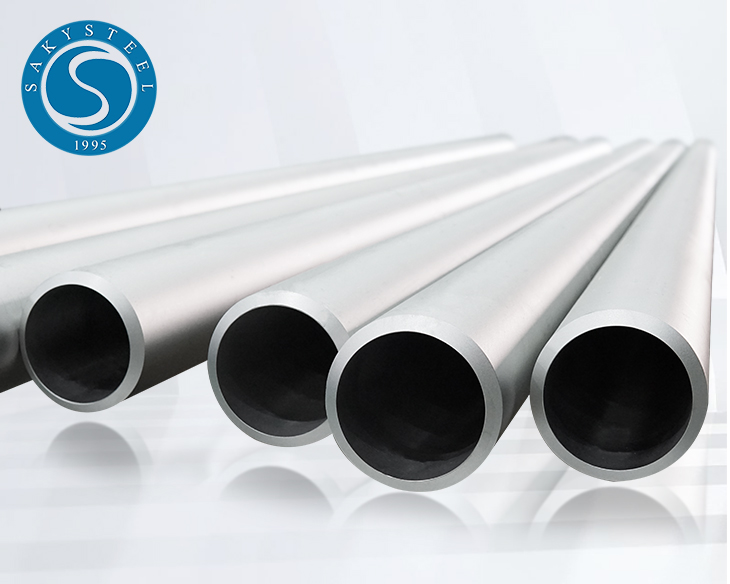

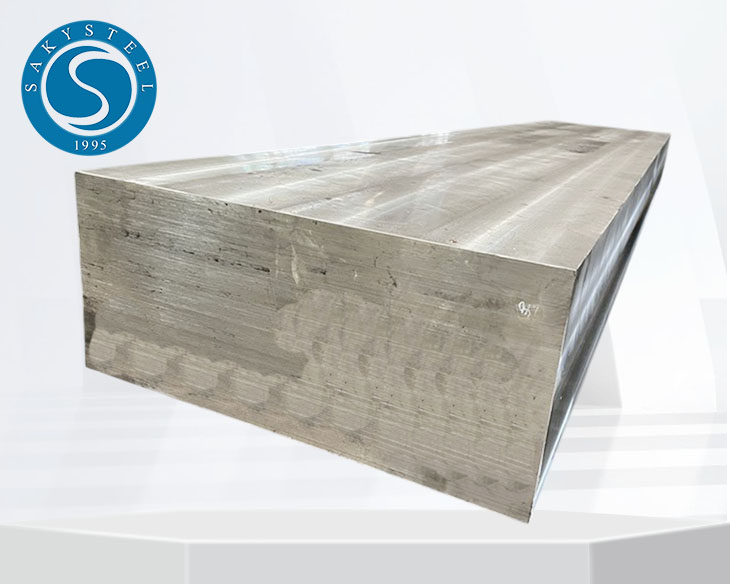

High-Quality Stainless Hexagon Bar for Industrial and DIY Projects

When I think of top-quality materials for my projects, stainless hexagon bars always come to mind. They are perfect for a variety of applications, whether you're crafting precision parts or constructing robust structures. With their excellent corrosion resistance and durability, these bars are designed to meet the demands of industries such as automotive, aerospace, and manufacturing. I know that choosing the right supplier is just as important as selecting the material itself, and I must say, the options available from reliable companies always stand out. Their commitment to quality ensures that I receive hexagon bars that are not only high in strength but also meet strict standards. By investing in stainless hexagon bars, I can trust that my projects will maintain integrity over time, making it a smart choice for both cost-effectiveness and performance. Don't compromise on quality when it comes to material selection—opt for stainless hexagon bars!

Stainless Hexagon Bar Stands Out Outperforms the Competition

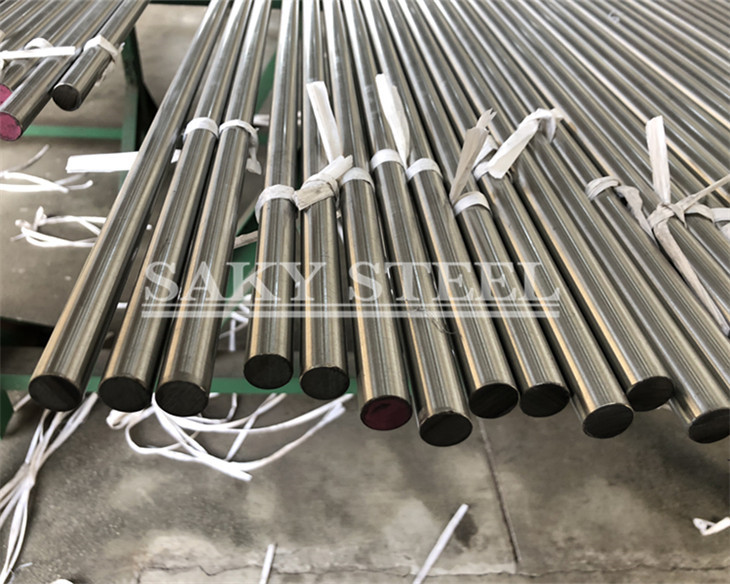

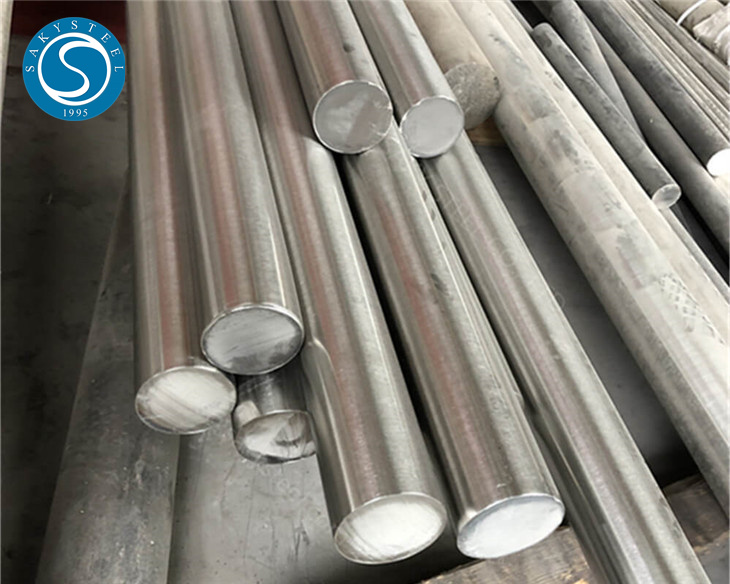

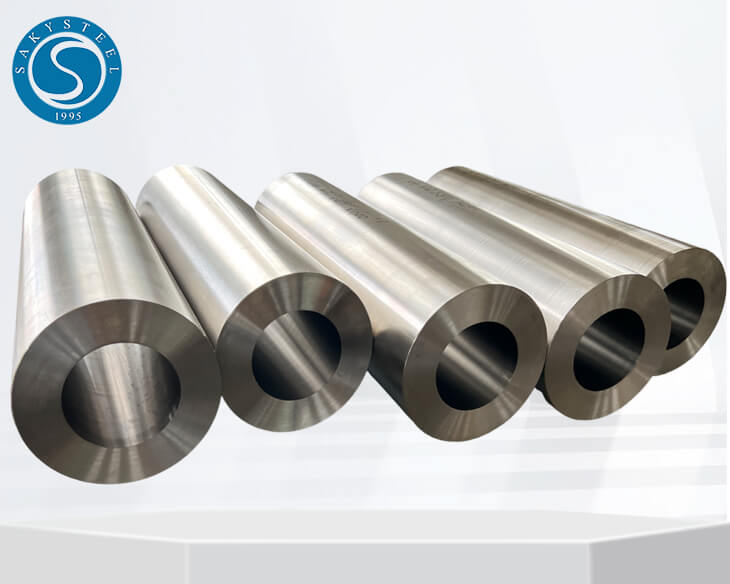

When it comes to selecting materials for demanding applications, the stainless hexagon bar emerges as a top contender that consistently outperforms the competition. Its unique geometry provides a host of advantages, from enhanced grip during machining to reduced weight in complex assemblies. The inherent corrosion resistance of stainless steel ensures longevity and durability, making it an ideal choice for industries ranging from construction to aerospace. Moreover, the versatility of the stainless hexagon bar allows for easy integration into a variety of projects. Whether used in fasteners, fittings, or structural components, its reliability has made it a staple in engineering and manufacturing processes worldwide. The ability to customize sizes and grades further enables procurement professionals to tailor their selections to meet specific project requirements, ensuring that their investments yield optimal performance under diverse conditions. In a market where quality and reliability are paramount, choosing superior materials like stainless hexagon bars is essential for maintaining a competitive edge. As businesses continue to seek innovative solutions to meet ever-evolving standards, this product stands ready to play a critical role in driving efficiency and success across various sectors.

Stainless Hexagon Bar Stands Out Outperforms the Competition

| Material Type | Diameter (mm) | Strength (MPa) | Corrosion Resistance | Thermal Conductivity (W/m·K) | Applications |

|---|---|---|---|---|---|

| 304 Stainless Steel | 10 | 520 | Good | 16 | Construction, Food Industry |

| 316 Stainless Steel | 12 | 570 | Excellent | 14 | Marine, Chemical Processing |

| 430 Stainless Steel | 8 | 450 | Fair | 24 | Automotive, Appliances |

| Duplex Stainless Steel | 16 | 800 | Very Good | 10 | Oil and Gas, Paper Industry |

Related Products