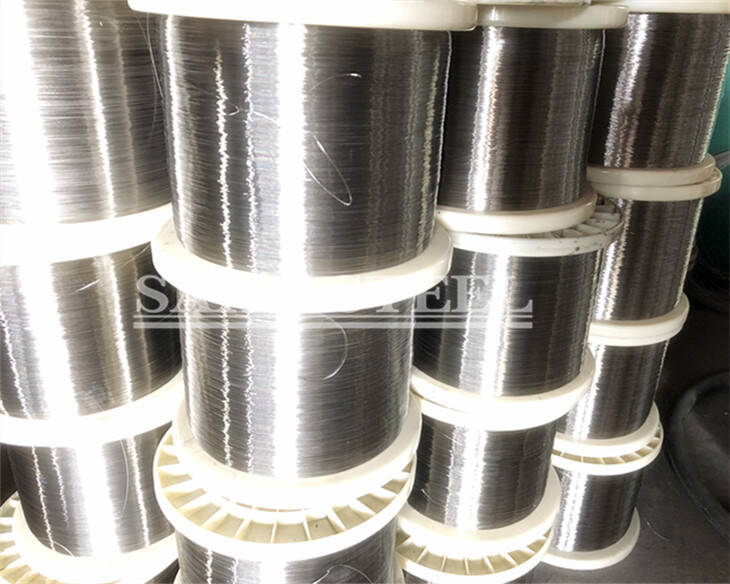

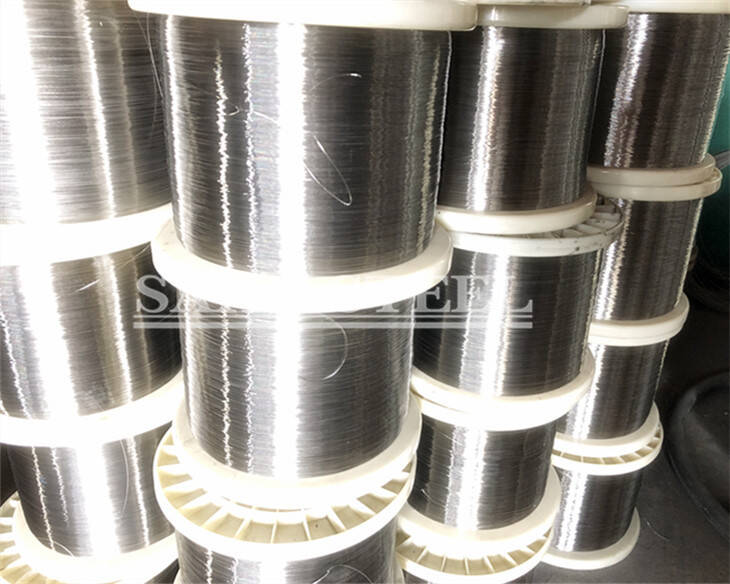

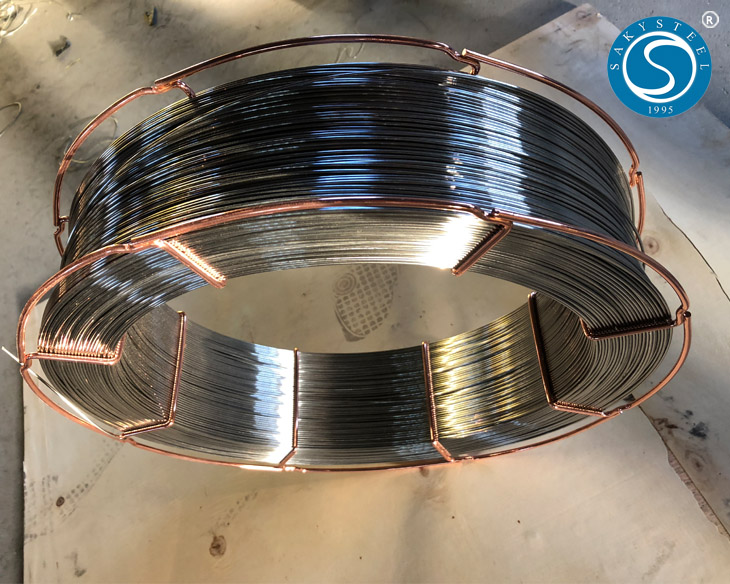

Premium Stainless Spring Wire for Reliable Performance and Durability

When sourcing high-quality stainless spring wire, I know how crucial it is to find a reliable supplier who understands my needs. This durable, versatile material is perfect for a variety of applications, from automotive to medical equipment. I appreciate the corrosion resistance that stainless spring wire offers, ensuring longer product life and performance under pressure. With options available in various gauges and finishes, I can tailor my order to meet specific project requirements. I often compare pricing and quality before making a decision, knowing that investing in the right wire can enhance my final product. Working with a knowledgeable company that provides excellent customer support makes the whole process smoother. Let’s not forget the quick turnaround times, which help me keep projects on schedule. If you’re in the same boat, let’s chat about how stainless spring wire can meet your needs effectively.

Stainless Spring Wire Sets the Industry Standard Custom Solutions,

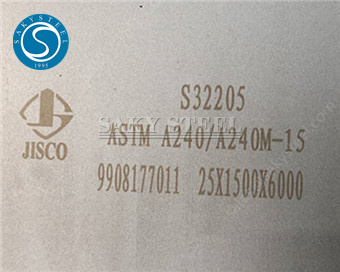

In today's competitive manufacturing landscape, high-quality stainless spring wire is essential for a variety of applications ranging from automotive to aerospace and medical devices. As industries evolve and demand for customized solutions increases, the ability to provide tailored stainless spring wire becomes a significant differentiator. Companies that understand the nuances of their clients' needs can create bespoke wire solutions that not only meet but exceed industry standards. Custom stainless spring wire is engineered for performance, offering superior tensile strength, corrosion resistance, and fatigue life. This adaptability allows manufacturers to specify wire diameter, material grade, and coating options tailored to specific applications. Collaborating closely with suppliers who offer comprehensive expertise in metallurgical properties and manufacturing processes can significantly enhance product reliability and lifespan. Moreover, employing advanced technology in wire production ensures consistent quality and reduces lead times, giving businesses a competitive edge in the global market. Ultimately, leveraging the capabilities of custom stainless spring wire can unlock new possibilities for innovation and efficiency in manufacturing. As global procurement professionals seek reliable partners, the emphasis on quality craftsmanship and customer-centric solutions will be pivotal in establishing long-term, successful business relationships. Investing in custom solutions not only paves the way for enhanced product performance but also drives overall operational excellence in a rapidly changing industrial environment.

Stainless Spring Wire Sets the Industry Standard Custom Solutions

| Type | Diameter (mm) | Tensile Strength (MPa) | Material Grade | Finish |

|---|---|---|---|---|

| Music Wire | 1.0 | 2000 | ASTM A228 | Bright |

| Stainless Steel | 2.0 | 1800 | ASTM A313 | Passivated |

| Oil-tempered | 3.0 | 2100 | ASTM A313 | Coated |

| Chrome Silicon | 4.0 | 2400 | ASTM A313 | Bright |

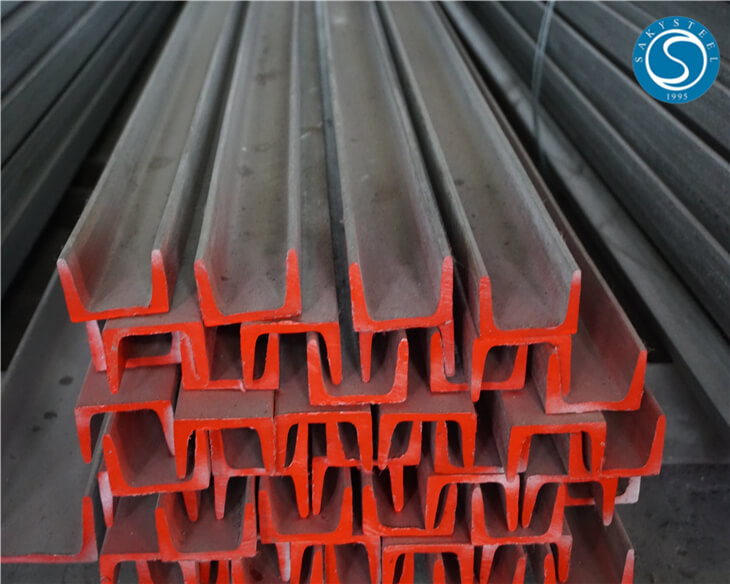

Related Products