Premium Stainless Steel 310 Pipe for Industrial Applications & Projects

If you’re in need of reliable, high-performance piping solutions, I can’t recommend Stainless Steel 310 Pipe enough. This versatile pipe is engineered to withstand extreme temperatures and corrosive environments, making it perfect for applications in petrochemical and aerospace industries. When considering your procurement options, keep in mind that the durability of 310 stainless steel guarantees an extended lifespan, reducing the need for frequent replacements. Many buyers, like myself, appreciate the superior mechanical properties and excellent weldability of this material, which ultimately contributes to lower maintenance costs. Whether you’re sourcing pipes for manufacturing or construction, our Stainless Steel 310 Pipe meets stringent industry standards, ensuring quality and performance every time. If you’re looking for a supplier who values both quality and customer satisfaction, I’m confident you’ll find satisfaction with our offerings. Let’s build a lasting partnership that supports your business needs!

Stainless Steel 310 Pipe Products For the Current Year

Stainless Steel 310 pipes are increasingly recognized in various industries for their high-temperature strength and excellent oxidation resistance. This year, global demand for these products continues to rise as manufacturers seek materials that can withstand extreme conditions while maintaining integrity. The unique composition of Stainless Steel 310, which primarily includes chromium and nickel, makes it ideal for applications in industries like aerospace, automotive, and chemical processing, where durability and performance are paramount. As businesses worldwide strive to enhance their operational efficiency and product reliability, sourcing high-quality Stainless Steel 310 pipes becomes essential. These pipes not only offer exceptional resistance to oxidation but also exhibit remarkable mechanical properties even at elevated temperatures. Companies looking for robust piping solutions should consider the advancements in production techniques that ensure consistency and reliability in these products. Procurement strategies should prioritize suppliers that maintain stringent quality control measures and certifications. This year's trends indicate a growing preference for suppliers who can provide detailed product specifications and traceability. Buyers are increasingly looking for partners who understand their unique requirements and can offer customized solutions. By investing in high-performance materials like Stainless Steel 310, businesses can ensure their operations are supported by pipes that meet both current demands and future challenges in various industrial applications.

Stainless Steel 310 Pipe Products For the Current Year

| Product Type | Diameter (inches) | Wall Thickness (mm) | Length (ft) | Standard |

|---|---|---|---|---|

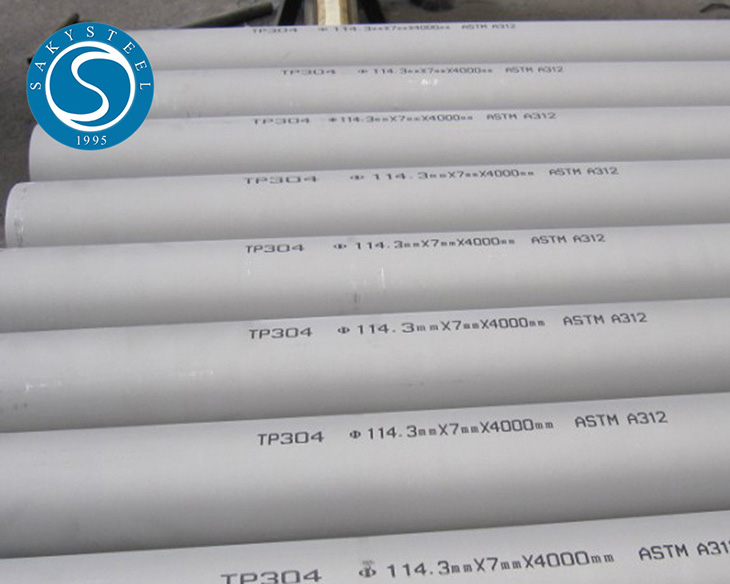

| Welded Pipe | 2 | 2.77 | 20 | ASTM A312 |

| Seamless Pipe | 3 | 3.05 | 30 | ASTM A312 |

| Square Pipe | 4 | 4.0 | 40 | ASTM A500 |

| Round Pipe | 5 | 4.5 | 25 | ASTM A312 |

| Custom Pipe | 6 | 5.0 | 50 | ASTM A312 |

Related Products