Premium Stainless Steel Needle Tube for Precision Applications

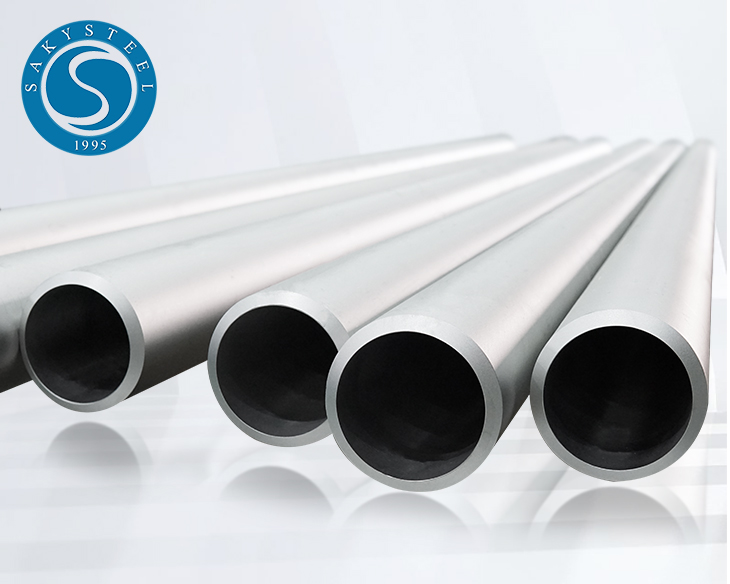

When it comes to sourcing high-quality stainless steel needle tubes, I understand the importance of durability and precision in your applications. Our stainless steel needle tubes are designed to meet the stringent demands of various industries, ensuring you get the reliability you need for your projects. The corrosion resistance of stainless steel makes these tubes perfect for both medical and industrial uses, allowing for safe and consistent performance. I know how vital it is to have the right specifications, and that’s why I offer customizable sizes and gauges to fit your exact requirements. Whether you're in pharmaceuticals or automotive, these tubes provide exceptional flexibility and strength. Plus, they come with competitive pricing and quick turnaround times, so you can maintain your workflow without delay. Don’t settle for less when you can have the best in stainless steel needle tubes tailored just for you. Let's enhance your operations together!

Stainless Steel Needle Tube Industry Giant Custom Solutions,

In the rapidly evolving landscape of industrial materials, the stainless steel needle tube industry stands out as a vital component for various applications, from medical devices to precision equipment. The demand for high-quality needle tubes is surging globally, driven by advancements in technology and healthcare. This presents an excellent opportunity for businesses to explore custom solutions that not only meet but exceed operational needs and regulatory standards. Custom stainless steel needle tubes are tailored to specific requirements, ensuring optimal performance and durability. Manufacturers can provide a variety of specifications, including sizes, wall thicknesses, surface finishes, and material grades. This customization is essential in sectors requiring precision, as it enhances product reliability while ensuring compliance with stringent safety standards. Partnering with a knowledgeable supplier can facilitate access to innovative designs and improved manufacturing techniques, ultimately leading to increased efficiency and lower operational costs. As the industry continues to grow, global procurement professionals should prioritize suppliers who offer not just products, but comprehensive solutions. Engaging with manufacturers that understand the unique challenges faced by diverse industries can lead to the development of cutting-edge products that cater to specific applications. By investing in quality and customization, businesses can stay ahead in a competitive marketplace, ensuring they meet the ever-evolving demands of their customers while achieving sustainable growth.

Stainless Steel Needle Tube Industry Giant Custom Solutions

| Material Type | Outer Diameter (mm) | Inner Diameter (mm) | Length (mm) | Customization Options |

|---|---|---|---|---|

| 304 Stainless Steel | 1.0 | 0.5 | 50 | Custom Length, Coating |

| 316 Stainless Steel | 1.5 | 1.0 | 75 | Custom Diameter, Sterilization |

| Medical Grade Stainless Steel | 2.0 | 1.5 | 100 | Custom Finishing, Marks |

| Nickel-Plated Stainless Steel | 1.2 | 0.8 | 60 | Surface Treatment, Custom Marking |

Related Products