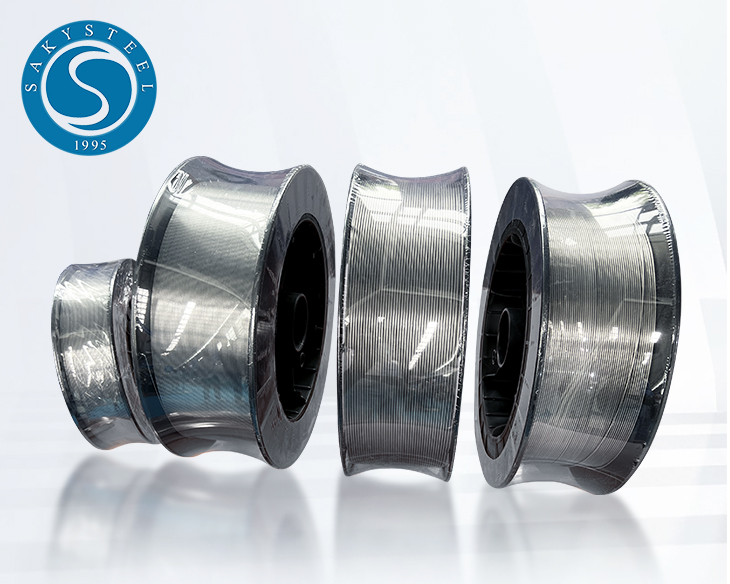

High-Quality 308L Welding Wire for Durable Metal Fabrication Projects

When it comes to welding solutions, I know how crucial it is to have reliable materials, and that’s where {308l Welding Wire} comes in. This wire is perfect for stainless steel applications, providing excellent performance in both high heat and corrosive environments. I’ve seen firsthand how it improves the quality of welds, minimizing defects and ensuring a clean finish. I often get asked about its versatility for different welding processes, and from my experience, it works exceptionally well with MIG and TIG techniques. Plus, the easy feedability makes it a favorite among seasoned professionals and beginners alike. If you’re seeking durability and strength without compromising on appearance, this is the wire you need. With {keyword1} and {keyword2}, we’re committed to offering the best products that meet industry standards, ensuring your projects are executed flawlessly every time. Don't miss out on this essential addition to your welding toolkit!

308l Welding Wire Industry Leaders Industry Giant

In the dynamic landscape of the 308L welding wire industry, leading players prioritize innovation, quality, and sustainability. As the demand for high-performance welding solutions grows globally, industry giants are continually enhancing their product offerings to meet diverse application needs. 308L welding wire, known for its excellent corrosion resistance and weldability, plays a crucial role in various sectors, including construction, shipbuilding, and manufacturing. Therefore, procurement professionals and global buyers must stay informed about the latest trends and technological advancements in welding materials. Key to maintaining a competitive edge, top industry leaders focus on leveraging cutting-edge technologies and stringent quality control measures. By investing in state-of-the-art production processes and sourcing high-grade raw materials, they ensure that their welding wires meet international standards and customer expectations. Moreover, sustainability has become a significant concern, prompting manufacturers to adopt eco-friendly practices while minimizing waste and energy consumption. This shift not only appeals to environmentally conscious buyers but also enhances corporate responsibility. For global purchasers, collaborating with an industry leader in the 308L welding wire market can lead to substantial long-term benefits. Such partnerships often provide access to superior products backed by extensive support services, including technical assistance and tailored solutions. As the industry continues to evolve, staying connected with top suppliers will be crucial for ensuring project success and achieving optimal welding outcomes across various applications.

308L Welding Wire Industry Leaders Industry Giant

| Dimension | Value | Description |

|---|---|---|

| Material Type | 308L | Low carbon content stainless steel suitable for welding. |

| Diameter Options | 0.8mm - 1.2mm | Available in various diameters for different applications. |

| Applications | Food and Chemical Industries | Widely used in food processing and chemical industries due to corrosion resistance. |

| Strength | Strength ≥ 520 MPa | Offers excellent tensile and yield strength for durability. |

| Welding Technique | TIG/MIG | Compatible with both TIG and MIG welding techniques. |

| Certification | ISO 9001 | Manufactured under strict quality control standards. |

| Packaging | Coils/Bundles | Packaged in coils or bundles for easy shipment and use. |

Related Products