DPM150 Flux Cored Hardfacing Welding Wire for Drill Rods

Short Description:

DPM150 is a cladding wire designed for high impact wear conditions. The weld metal structure is dense, the hardness is high, and it has excellent wear resistance and good crack resistance. It is suitable for cladding repair or preventive strengthening of workpieces such as oil drill pipes, coal mine scrapers, and breaker hammers.

DPM150 Flux Cored Hardfacing Welding Wire:

DPM150 is a self-shielded flux-cored welding wire designed for hardfacing drill rods and components exposed to severe abrasion and moderate impact in mining, petroleum, and coal drilling industries. It produces a dense martensitic structure with dispersed hard carbides.DPM150 is a high-performance flux-cored welding wire specifically designed for hardfacing drill rods and mining tools. It offers excellent abrasion resistance with hardness up to HRC 60 and superior crack resistance under multi-layer welding. Self-shielded and easy to operate, DPM150 is ideal for field applications without shielding gas. Suitable for oilfield equipment, coal mining machinery, and construction tools requiring strong wear protection and impact durability.

Specifications Of DPM150 Hardfacing Welding Wire:

| Grade | DPM150,DPM300,DPM700,DPM900,etc. |

| Standard | ISO 14700 / EN 14700 (e.g. T Fe15 Equivalent); Custom specifications available upon request. |

| Surface | Polished bright, Smooth |

| Diameter | 1.6mm / 2.0mm / 2.4mm |

| Hardness | HRC 55–60 |

| Welding Method | Open Arc (Self-shielded Flux Cored Wire) |

| Length | 100 mm TO 6000 mm, customizable |

| Typical Application | Drill Rod Hardfacing / Mining Wear Parts |

DPM150 Welding Wire Chemical Composition:

| Grade | C | Si | Mn | P | S | Mo |

| DPM150 | 0.71 | 1.0 | 2.1 | 0.08 | 0.08 | 0.35 |

| DPM300 | 0.73 | 1.01 | 2.2 | 0.04 | 0.05 | 0.51 |

| DPM700 | 0.69 | 1.2 | 2.1 | 0.08 | 0.08 | 0.35 |

| DPM900 | 0.71 | 1.2 | 2.1 | 0.08 | 0.08 | 0.35 |

Mechanical Properties :

| Grade | Typical | Hardness (HRC) |

| DPM150 | 55 | 52–57 |

| DPM300 | 59 | 57-62 |

| DPM700 | 63 | 60-65 |

| DPM900 | 64 | 60-65 |

Welding Parameters:

| Grade | Wire Diameter (mm) | Voltage (V) | Current (A) | Stick-out (mm) | Gas Flow Rate (L/min) |

| DPM150 | 1.6 | 26–36 | 260–360 | 15–25 | 18–25 |

| DPM300 | 1.6 | 26–36 | 260–360 | 15–25 | 18–25 |

| DPM700 | 1.6 | 26–36 | 260–360 | 15–25 | 18–25 |

| DPM900 | 1.6 | 26–36 | 260–360 | 15–25 | 18–25 |

Main Features DPM150 Welding Wire:

• Reasonable and sufficient hardness (HRC 52–57), excellent wear resistance, increases drill rod joint life by more than 3 times;

• Reduces breakage and lowers repair and replacement costs. Even when wear layer is thinned, the bonding strength with the drill head remains strong, and there is no visible interface between the hardfacing and the drill head;

• Metal loss due to abrasion of FRW-DPM150 is less than 12% of traditional wear-resistant materials;

• Excellent weldability and smooth appearance of the weld bead;

• Crack-resistant: No visible cracks after welding and cooling under normal conditions;

• Beautiful arc shape, smooth bead, and minimal spatter;

• Can be applied to surface overlay welding on drill rods, drill collars, stabilizers, and various oilfield and mining tool surfaces;

• Compatible with multiple hardfacing materials.

DPM150 Welding Wire Welding Notes:

1.Clean the wear-resistant surfacing area +1" (25.4mm) beyond the edge (remove oil, rust, oxide, etc.). Ensure strong bonding between surfacing layer and tool joint is key for durability.

2.Use mixed gas (75%-80% Ar + CO₂) or 100% CO₂ shielding gas, recommended flow rate: 20–25 L/min.

3.Preheating and interpass temperature control required.

4.Post-weld slow cooling is required. Use insulation blanket if needed.

5.If post-weld temperature drops below 66°C, tempering is recommended.

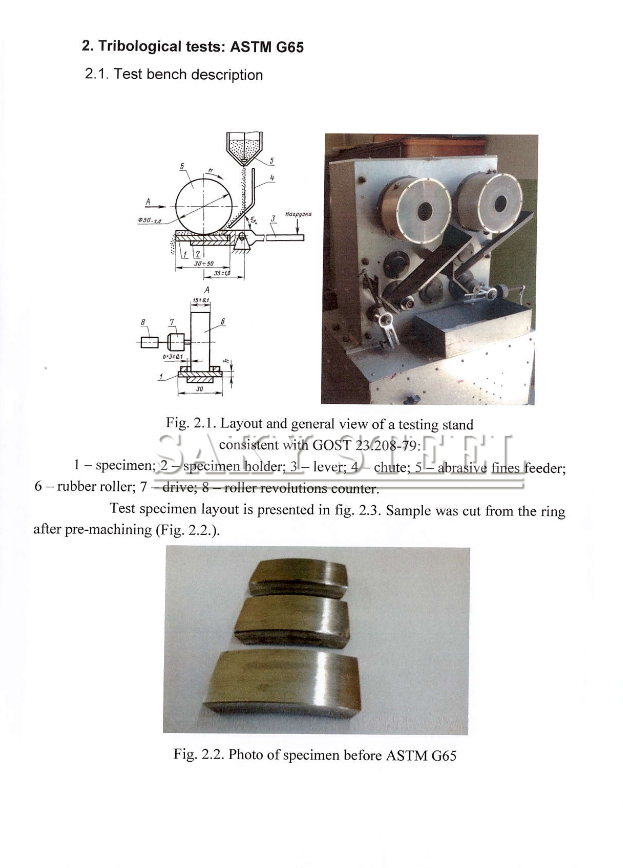

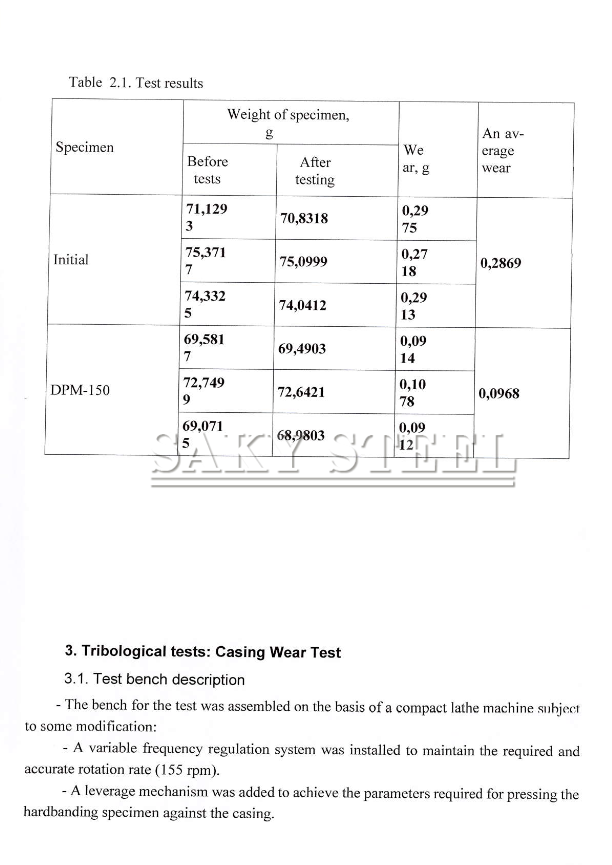

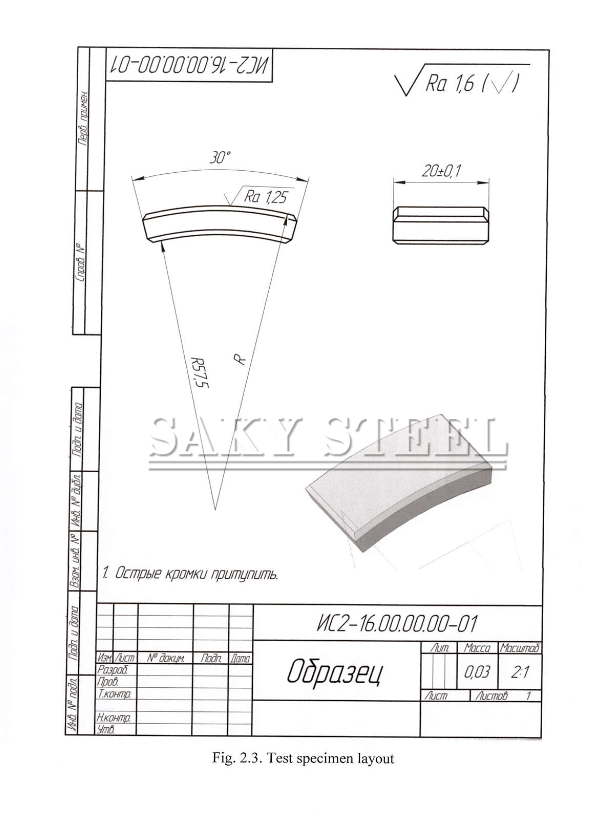

TEST REPORT DPM150:

DPM150 Hardfacing Welding Wire Applications:

• Hardfacing of drill rods used in oil drilling and coal mining

• Wear-resistant coating for buckets, conveyor scrapers, and sprockets in mining machinery

• Reinforcement of oilfield tools such as drill bits and reamers

• Surface hardfacing of excavator parts, bulldozer blades, and mixer paddles

• Protective overlay for crushers, rollers, and fan blades in cement and steel industries

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

DPM150 Flux Cored Welding Wire Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,