High-Quality 321 Stainless Steel Tubing for Your Projects - Fast Delivery

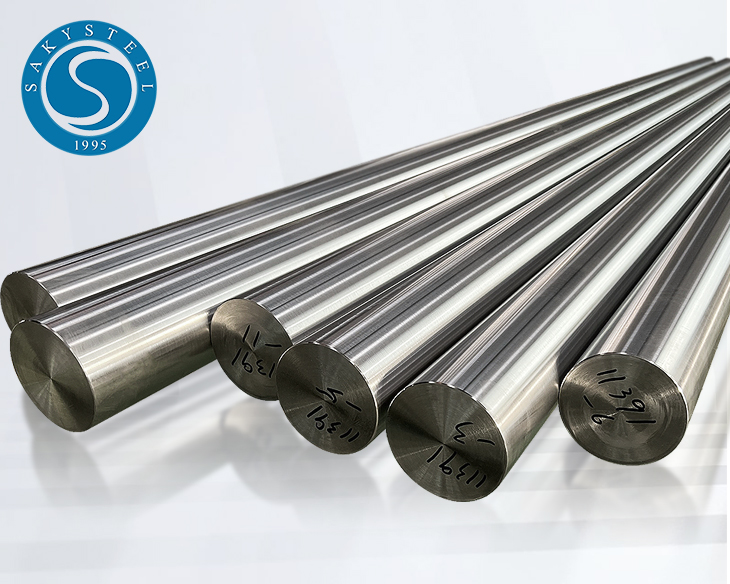

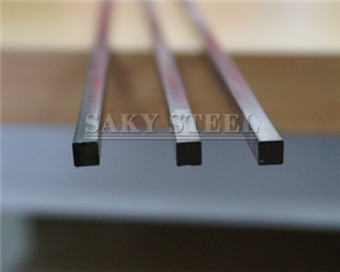

When I first encountered 321 Stainless Steel Tubing, I knew it was the right choice for my projects requiring excellent corrosion resistance and high-temperature strength. This tubing is perfect for applications in aerospace, chemical processing, and even automotive industries. The seamless welding capability ensures that I can achieve strong joints without sacrificing performance. As I researched, I found the 321 grade offers a wonderful combination of ductility and weldability, making it super easy to work with while still providing superior durability. Purchasing in bulk has become a breeze thanks to the reliable supply chain from leading manufacturers, ensuring I get the quality I need consistently. Whether you're looking to enhance your production efficiency or require tubing that can withstand the toughest conditions, 321 Stainless Steel Tubing is a robust option that meets my demanding standards. Let's talk about how this product can meet your specific needs and help elevate your projects to the next level!

321 Stainless Steel Tubing Industry Leaders Your End-to-End Solution

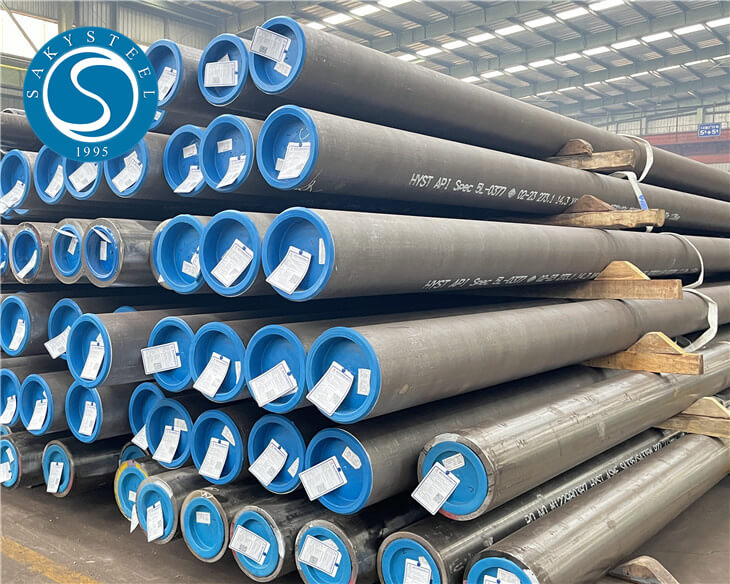

In the realm of stainless steel tubing, 321 stainless steel is recognized for its exceptional resistance to corrosion and high-temperature environments. Ideal for a variety of applications, this alloy is especially popular in the aerospace, chemical, and automotive industries. As global demand for high-quality stainless steel tubing continues to rise, businesses seeking reliable partners can benefit immensely from an end-to-end solution that encompasses everything from sourcing raw materials to delivering finished products. Leading players in the industry understand the importance of quality and efficiency. With a robust supply chain, these leaders are able to provide not only the tubing itself but also extensive support in terms of design, manufacture, and distribution. This comprehensive approach ensures that buyers receive precisely what they need, tailored to their specific requirements. By leveraging cutting-edge technology and sustainable practices, industry leaders help clients streamline operations, reduce costs, and enhance product performance. As procurement strategies evolve, it is crucial for global buyers to collaborate with partners who can navigate the complexities of international trade while maintaining stringent quality control. By forming strategic alliances with reputable suppliers and manufacturers, businesses can secure a competitive edge in their markets. Ultimately, investing in high-quality 321 stainless steel tubing from established leaders will empower companies to achieve their operational goals and drive long-term success.

321 Stainless Steel Tubing Industry Leaders - Your End-to-End Solution

| Type | Specifications | Applications | Thickness (mm) | Diameter (mm) | Length (m) |

|---|---|---|---|---|---|

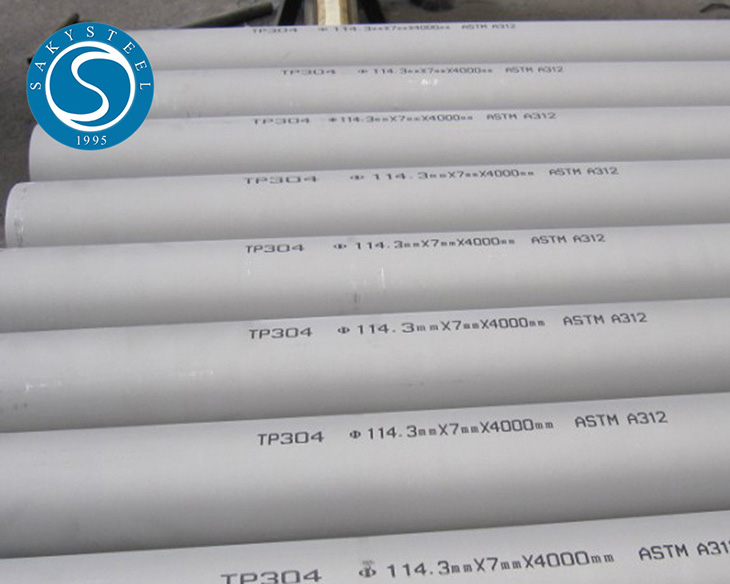

| Seamless | ASTM A312 | Chemical Processing | 1.5 | 25 | 6 |

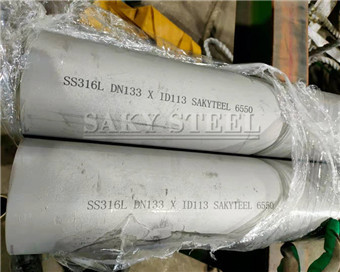

| Welded | ASTM A213 | Oil & Gas | 2.0 | 50 | 8 |

| Drawn | ASTM A269 | Construction | 1.2 | 20 | 5 |

| Annealed | ASTM A240 | Medical | 3.0 | 30 | 7 |

Related Products