4140 Tool Steel: Quality Options for Your Metalworking Projects

When it comes to high-performance materials, I often turn to 4140 Tool Steel for its exceptional strength and versatility. Whether you’re crafting precision tools or manufacturing heavy machinery parts, this steel is a fantastic choice for its hardening capabilities and resistance to wear. Having worked with various clients, I know they appreciate 4140 for its ability to withstand tough conditions, making it ideal for heavy-duty applications. If you're in need of reliable material that can enhance your production efficiency, 4140 Tool Steel may just be the solution. I’ve seen how this steel can improve the lifespan of equipment and reduce downtime for maintenance. It's also available in different forms, so you can easily find what fits your project. My experience indicates that those who choose 4140 often return for more, knowing they made the right choice. Let's make your next project a success with 4140 Steel!

4140 Tool Steel Service Delivers Unmatched Quality

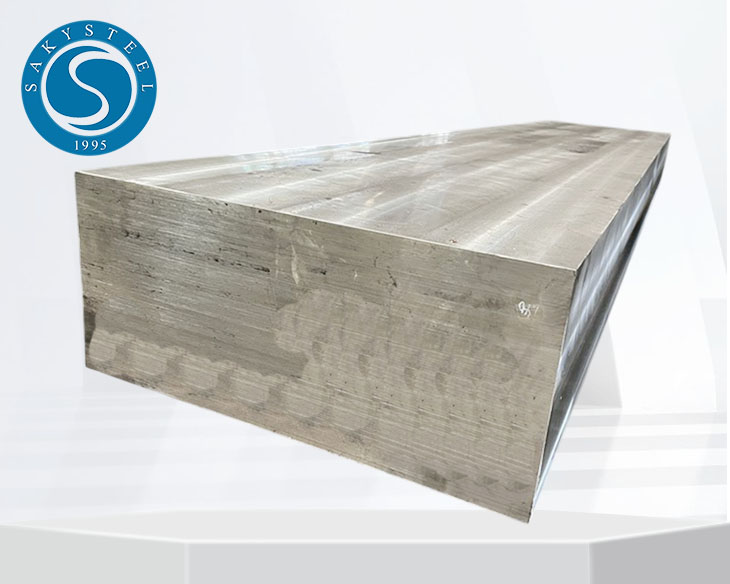

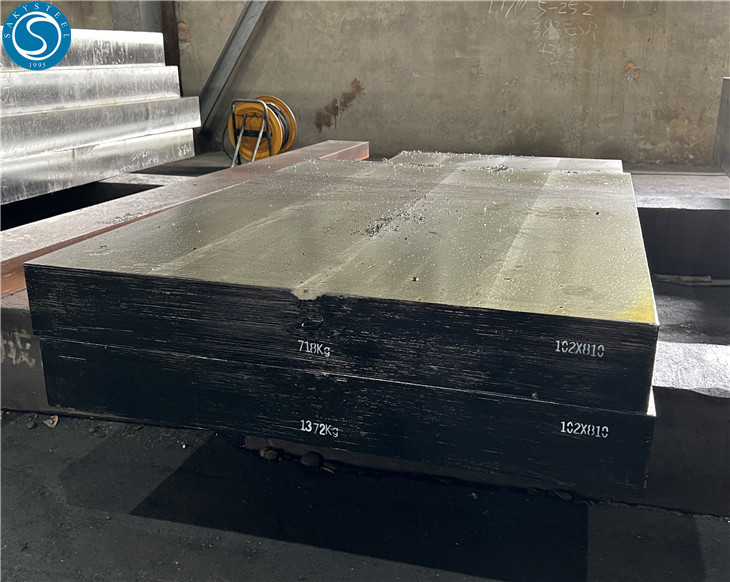

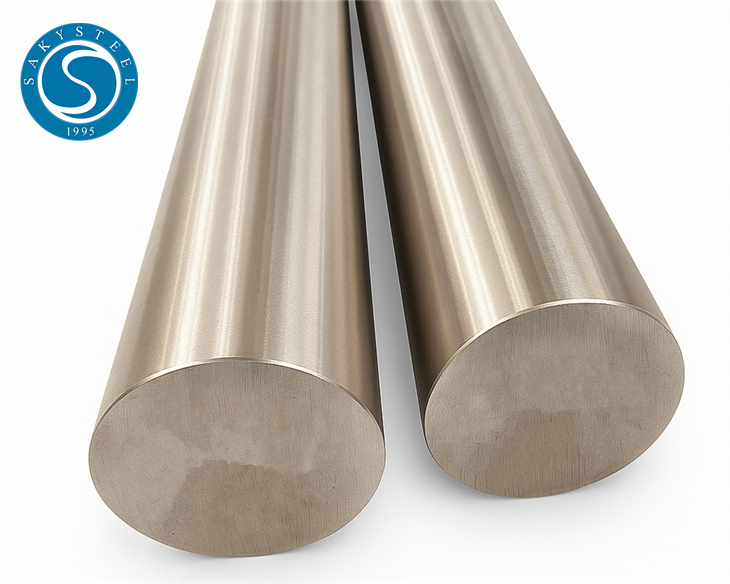

When it comes to sourcing high-quality tool steel, 4140 tool steel stands out as an exceptional choice. Known for its superior strength and hardness, this versatile alloy is utilized in various industries, from automotive to aerospace, where precision and durability are paramount. Its unique combination of chromium, molybdenum, and carbon provides enhanced wear resistance and toughness, making it ideal for manufacturing robust tools and components that withstand rigorous operational demands. In today's competitive market, sourcing reliable suppliers who can consistently deliver unmatched quality is crucial. Our commitment to excellence ensures that all 4140 tool steel products meet strict industry standards and customer specifications. By employing advanced manufacturing processes and rigorous testing methods, we guarantee a final product that not only meets but exceeds expectations. Whether you require bars, plates, or custom shapes, our solutions are tailored to support your specific projects, helping you maintain your edge in the marketplace. Furthermore, understanding the importance of global connectivity, we facilitate seamless procurement processes for international clients. Our efficient logistics and timely delivery schedules ensure that you receive your orders promptly, allowing you to streamline your operations and enhance productivity. When you choose our 4140 tool steel service, you gain a partner dedicated to providing the quality you need to succeed in your endeavors.

4140 Tool Steel Service Delivers Unmatched Quality

| Material Type | Hardness (HRC) | Tensile Strength (MPa) | Yield Strength (MPa) | Applications |

|---|---|---|---|---|

| 4140 Steel | 28-32 | 620 | 450 | Machinery, Tools, Automotive |

| 4140 HT (Heat Treated) | 32-36 | 680 | 485 | High-stress applications, Aerospace |

| 4140 Annealed | 16-24 | 460 | 310 | Welding, Forging |

Related Products