Nylon Coated Stainless Steel Wire: Durable, Versatile Solutions for All Needs

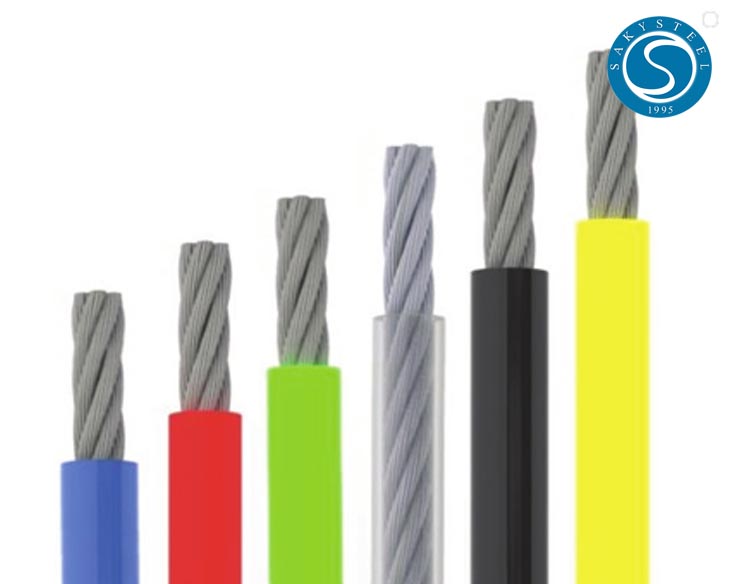

When I first started searching for durable materials, I found the benefits of Nylon Coated Stainless Steel Wire were hard to ignore. This wire combines the strength of stainless steel with a protective nylon coat, making it corrosion-resistant and perfect for various applications, whether in construction, marine, or crafting fields. I appreciate how the nylon coating not only enhances durability but also provides a secure grip, preventing slippage in tension applications. If you're considering quality, this wire truly fits the bill. It's great for projects that need reliable performance and can withstand the elements without compromising integrity. With my firsthand experience, I highly recommend this product. It's not just about the specs; it's about reliability, performance, and peace of mind. Don’t settle for less when you can have a combination of strength and versatility at your fingertips.

Nylon Coated Stainless Steel Wire Dominates Ahead of the Curve

As the demand for high-performance materials continues to rise, nylon-coated stainless steel wire has positioned itself as a frontrunner in the global market. This innovative product combines the strength and durability of stainless steel with the versatility and protection offered by nylon coating. These qualities make it ideal for a variety of applications, ranging from construction and manufacturing to automotive and telecommunications industries. Nylon-coated stainless steel wire not only enhances corrosion resistance but also provides a level of flexibility that allows for easier handling and installation. Its smooth surface reduces friction, making it a preferred choice in applications where wear and tear are significant concerns. By adopting this material, businesses can improve their operational efficiency while ensuring that their projects meet high standards of quality and durability. For global purchasers, investing in nylon-coated stainless steel wire is a strategic move that offers a competitive edge. With its growing popularity and extensive range of applications, this material is set to dominate the market. Companies looking to enhance their product offerings or streamline their supply chains should consider incorporating this technology to meet the evolving demands of their customers. Embracing innovations like nylon-coated stainless steel wire will not only boost operational performance but also pave the way for sustainable growth in an ever-evolving industrial landscape.

Nylon Coated Stainless Steel Wire Dominates Ahead of the Curve

| Feature | Description | Applications | Benefits |

|---|---|---|---|

| Material | Nylon Coated Stainless Steel | Construction, Marine, Automotive | Corrosion Resistance, Durability |

| Diameter Range | 0.5 mm - 10 mm | Cable Assemblies, Hoisting | Versatile Sizing Options |

| Breaking Strength | Up to 2000 lbs | Heavy Lifting, Rigging | High Load Capacity |

| Temperature Tolerance | -40°C to 90°C | Outdoor Use, Industrial | Reliable in Harsh Environments |

| Coating Characteristics | UV Resistant, Smooth Finish | Aesthetic Applications, Safety | Enhanced Safety and Look |

Related Products