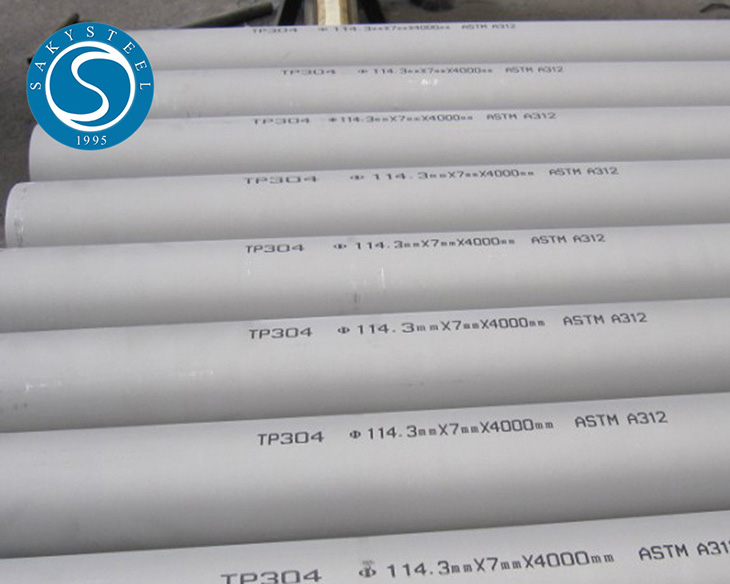

Quality SS Seamless Tube for Industrial Applications & Projects

When I think of the perfect solution for my industrial needs, the Ss Seamless Tube always comes to mind. This high-quality product stands out thanks to its exceptional durability and resistance to corrosion, making it ideal for everything from construction to automotive applications. I appreciate how the seamless design eliminated weak points, ensuring that I get reliable performance no matter the conditions. I often search for options that offer both value and performance, and this seamless tube does just that. Whether it's for heavy-duty use or precision applications, I know I can rely on its consistency to meet demanding standards. Plus, the flexibility in customization helps me find the right fit for my specific requirements. It's a game-changer for any B2B purchaser looking to invest in long-lasting materials without compromising quality. If you're in the market for top-tier seamless tubes, this is definitely worth considering!

Ss Seamless Tube Dominates Market Leader

In the competitive world of manufacturing, seamless tubes have emerged as a vital component across various industries, including oil and gas, construction, and automotive sectors. This rise in demand can be attributed to the superior strength, durability, and flexibility of seamless tubes, which outshine traditional welded alternatives. As global procurement professionals are continuously on the lookout for reliable suppliers, seamless tubes have become the go-to choice for high-performance applications. The market for seamless tubes is characterized by rapid advancements in technology and production methods, enabling manufacturers to achieve higher efficiency and lower costs. This evolution has made it essential for stakeholders in the supply chain to partner with leaders who not only understand market trends but also commit to quality and innovation. By selecting a top-tier manufacturer, businesses can ensure they are investing in products that meet stringent industry standards, ultimately driving their success in a competitive landscape. Moreover, the seamless tube market is poised for growth, fueled by increasing infrastructure development and rising energy demands worldwide. Procurement professionals must stay informed about material properties, specifications, and the latest breakthroughs in seamless tube technology. This will empower them to make strategic purchasing decisions that enhance operational performance and secure their position as industry leaders in their respective markets.

Ss Seamless Tube Market Overview

| Dimension (mm) | Material Type | Application Area | Production Volume (tons/year) | Market Share (%) |

|---|---|---|---|---|

| 25 x 5 | Austenitic Stainless Steel | Automotive | 15000 | 35 |

| 30 x 10 | Ferritic Stainless Steel | Construction | 12000 | 30 |

| 40 x 15 | Duplex Stainless Steel | Oil & Gas | 8000 | 25 |

| 15 x 3 | Martensitic Stainless Steel | Aerospace | 6000 | 10 |

Related Products