316LVM UNS S31673 ASTM F138 Stainless Steel Round Bar

Short Description:

Buy 316LVM stainless steel bars certified to ASTM F138. Vacuum arc re-melted and biocompatible, ideal for surgical implants, medical instruments, and critical biomedical applications.

316LVM stainless steel bar is a vacuum melted, low-carbon version of 316L stainless steel specifically designed for medical and surgical use. Produced using Vacuum Induction Melting (VIM) followed by Vacuum Arc Remelting (VAR), 316LVM offers excellent cleanliness, corrosion resistance, and biocompatibility, making it suitable for implants and critical biomedical components. Certified to ASTM F138 and ISO 5832-1, this alloy meets the stringent requirements of the medical device industry. SAKY STEEL provides 316LVM round bars with tight tolerances, smooth surface finishes, and full traceability for OEMs and healthcare equipment manufacturers.

| Specifications of 316LVM Stainless Steel Bar: |

| Specifications | ASTM A138 |

| Grade | 316LVM |

| Length | 1000 mm – 6000 mm or as requested |

| Diameter Range | 10 mm – 200 mm (custom available) |

| Technology | Hot Rolled / Forged / Cold Drawn |

| Surface Finish | Bright, Peeled, Polished, Turned, Pickled |

| Form | Round, Square, Flat, Hexagonal |

| 316LVM round bar Equivalent Grades: |

| STANDARD | UNS | WNR. |

| SS 316LVM | S31673 | 1.4441 |

| Chemical Composition 316LVM surgical steel bar: |

| C | Cr | Cu | Mn | Mo | Ni | P | S |

| 0.03 | 17.0-19.0 | 0.05 | 2.0 | 2.25-3.0 | 13.0-15.0 | 0.03 | 0.01 |

| Mechanical Properties Of Stainless Steel 316LVM Round Bar: |

| Grade | Tensile Strength | Yield Strength | Elongation | Reduction |

| 316LVM | Ksi-85 MPa – 586 | Ksi-36 MPa – 248 | 57% | 88 |

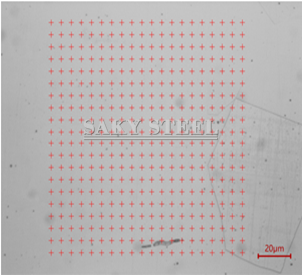

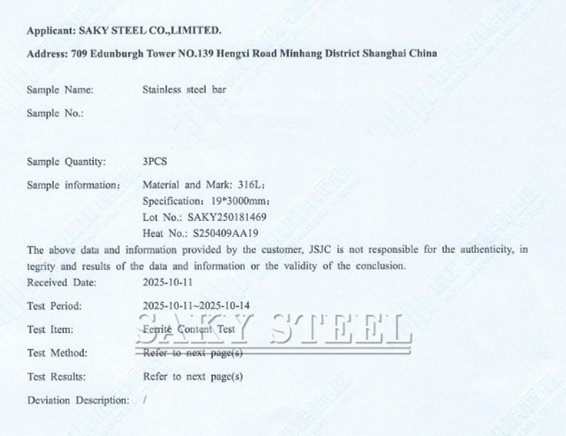

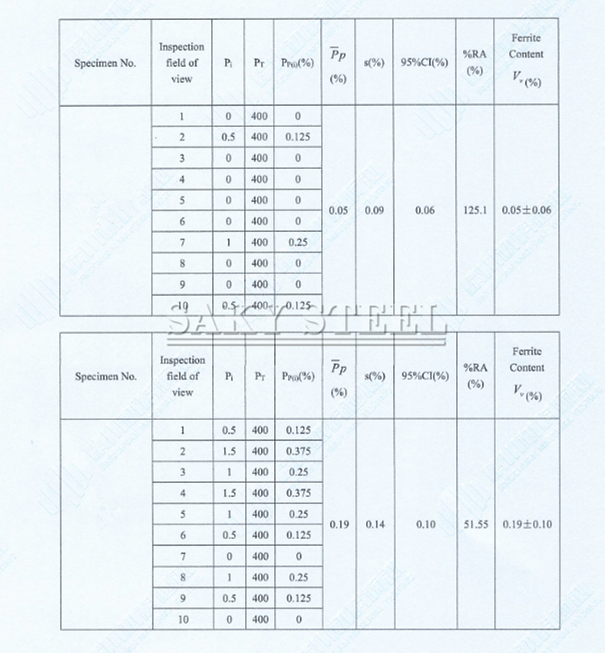

| Ferrite Content Testing: |

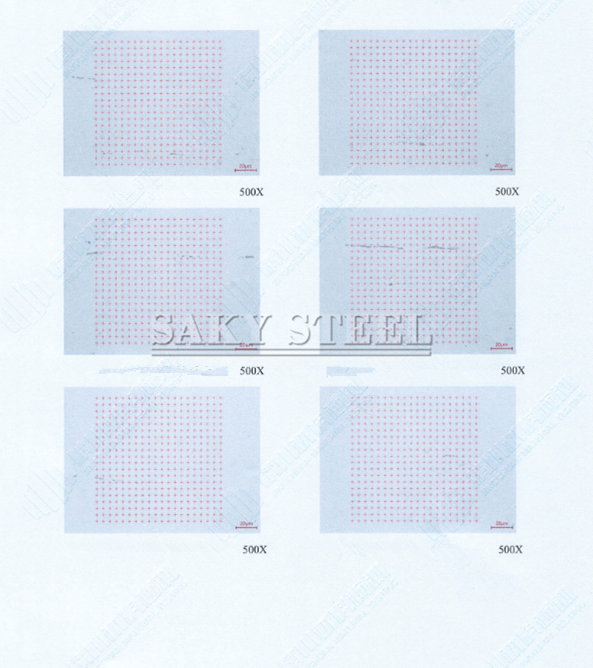

To ensure reliable mechanical properties and corrosion resistance, the ferrite content of stainless steel 316LVM bars is measured according to ASTM E562-19e1, using the manual point-count method.

According to the standard, the smaller the required measurement precision, the greater the number of fields and grid points needed. For example, to achieve a precision of less than 2 %, approximately 30 fields with a 10 × 10 grid (100 points) or 5 fields with a 20 × 20 grid (400 points) are typically required.

| Visual Area Fraction Estimate (%) | Recommended Grid Size (Number of Points) |

| 2 – 5 % | 100 points |

| 5 – 10 % | 49 points |

| 10 – 20 % | 25 points |

| > 20 % | 16 points |

|

|

| 10*10=100 (Magnified 100 times) | 20*20=400 (Magnified 500 times) |

The finer the grid and the larger the number of observation fields, the higher the accuracy — and consequently, the higher the testing cost. This method ensures that the ferrite phase in stainless steel is accurately quantified, guaranteeing product stability and consistent performance in critical applications such as pressure vessels, welded structures, and marine components.

The test is performed according to ASTM E562-19e1 (Metallographic Point Count Method) and/or Magnetic Method, and a Ferrite Content Test Certificate is issued with the measured Fe% value.

All test results are documented and traceable.The combination of magnetic and metallographic methods ensures accuracy and compliance with ASTM, EN, and ISO standards.

|

|

|

| In-Site Test Items Applicable for Bars: |

To ensure the highest quality and performance, all SAKY STEEL bar products can be tested through a comprehensive range of in-site inspections. These tests verify chemical composition, mechanical integrity, and microstructural stability directly on materials before shipment or after processing.

| No. | Test Item | Description | Applicable Materials / Range | Note |

|---|---|---|---|---|

| 1 | In-situ Hardness Test | Measures surface hardness (HB/HRC/HV) to verify heat treatment or forging condition | All bar types — stainless steel, nickel alloys, titanium, aluminum | Standard test for bars |

| 2 | In-situ Metallographic Test | Examines grain structure, carbide distribution, and phase ratio | Stainless steel, nickel alloy, titanium | Detects overheating or improper heat treatment |

| 3 | In-situ Chemical Composition Test (PMI) | Confirms material grade and chemical composition using XRF or OES | All metallic bars | Prevents material mix-up |

| 4 | Residual Stress Test | Evaluates internal stress after heat treatment or machining | Steel, nickel, titanium bars | Prevents deformation or cracking |

| 5 | Stress and Strain Test | Determines mechanical properties such as yield strength and modulus | Structural or high-strength bars | Optional mechanical verification |

| 6 | Non-destructive Test of Ferrite Number | Measures FN value and ferrite-austenite balance | Austenitic / Duplex stainless steel bars | Not applicable for aluminum or titanium |

| 7 | Thickness Test of Coatings | Measures coating or anodized layer thickness | Plated, coated, or anodized bars | For special surface-treated bars only |

| 8 | In-situ Simulated Corrosion Test | Evaluates corrosion resistance per NACE or custom spec | Stainless steel, nickel alloy bars | Used in marine or chemical projects |

| 9 | Ultrasonic Flaw Detection (UT) | Detects internal defects and inclusions in solid bars | All metallic solid bars | Replaces wall-thickness test (for tubes only) |

| Chemical Composition Analysis: |

At SAKY STEEL, we ensure every batch of material meets the international standards through comprehensive chemical composition analysis. Our advanced laboratory is equipped with state-of-the-art instruments, including Optical Emission Spectrometer (OES), Positive Material Identification (PMI) device, Inductively Coupled Plasma Spectrometer (ICP), and X-Ray Fluorescence (XRF) analyzer.

| Method (Abbreviation) | Full English Name / Description | Typical Purpose |

|---|---|---|

| OES | Optical Emission Spectrometric Analysis | Rapid alloy composition testing |

| PMI | Positive Material Identification | On-site material grade verification |

| ICP | Inductively Coupled Plasma Spectrometric | Precise trace element analysis |

| XRF | X-Radial Fluorescence Spectrometric | Multi-element analysis for metal and alloy samples |

| Carbon & Sulfur Analyse | Carbon and Sulfur Analyzer | Determination of C and S content in steels |

| N/O/H Analyse | Nitrogen, Oxygen, and Hydrogen Analyzer | Gas element detection in metals |

| Chemical Titration | Classical Wet Chemistry Method | Standard chemical verification |

| Spectrophotometer | UV-Visible Spectrophotometric Analysis | Trace element colorimetric testing |

| FAAS | Flame Atomic Absorption Spectroscopy | Quantitative element measurement |

| GC | Gas Chromatography | Separation and analysis of gases or volatile compounds |

| IC | Ion Chromatography | Analysis of anions and cations in solutions |

| GD-MS | Glow Discharge Mass Spectrometry | Depth profiling and surface analysis |

| TOC Analyzer | Total Organic Carbon Analyzer | Organic content testing |

| IR Spectrometer | Infrared Spectrometry | Molecular structure and compound identification |

| Mechanical Performance Testing: |

At SAKY STEEL, we conduct a full range of mechanical performance tests to ensure the strength, toughness, and durability of every stainless steel, alloy steel, and nickel alloy product we deliver.We perform comprehensive tests such as tensile strength, yield strength, elongation, hardness (Brinell, Rockwell, Vickers, Leeb), bending, impact toughness, fatigue, and fracture toughness (KIC and CTOD). These tests precisely measure the mechanical behavior of materials under various loads and environments, ensuring full compliance with ASTM, EN, GB, and ISO standards.

| Test Item | Full Name / Description |

|---|---|

| Brinell / Rockwell / Vickers hardness test | Hardness measurement for different metal types |

| Knoop / Leeb / Webster hardness test | Portable and micro hardness testing |

| Shore / Mohs / Pencil hardness test | Surface hardness assessment |

| Nano indentation test | Micro/nano mechanical property analysis |

| Room / high temperature tensile test | Tensile strength testing at ambient or elevated temperatures |

| Elastic modulus / Poisson’s ratio test | Elastic deformation characteristics |

| Tensile strain hardening exponent (n) test | Material strain-hardening behavior |

| Plastic strain ratio (r) test | Plastic deformation property |

| Bend test | Ductility and formability testing |

| Reverse bend test | Fatigue and flexibility assessment |

| Flaring / flanging / flattening test | Tube and pipe forming performance evaluation |

| Low / room temperature impact test | Impact toughness testing under various conditions |

| Temper brittleness assessment | Evaluation of temper embrittlement |

| Fracture toughness test (KIC test) | Crack resistance under stress |

| Shear test | Shear strength measurement |

| Fatigue test | Durability under cyclic loading |

| Endurance creep test | Long-term deformation resistance |

| Crack Tip Opening Displacement (CTOD) test | Fracture mechanics and crack propagation analysis |

| Non-standard mechanical test | Customized testing based on client requirements |

| Applications of 316LVM Stainless Steel Bar: |

316LVM stainless steel bar is widely used in medical and surgical applications where biocompatibility, corrosion resistance, and high purity are critical. Its vacuum-melted production process ensures minimal inclusions and excellent cleanliness, making it suitable for:

-

Orthopedic implants, such as bone plates, screws, and joint replacements

-

Cardiovascular devices, including stents, pacemaker components, and heart valves

-

Dental tools and implants, due to its resistance to body fluids and sterilization cycles

-

Surgical instruments, where non-magnetic, corrosion-resistant materials are required

-

Spinal fixation systems and craniofacial devices

-

Veterinary surgical components and specialized precision tools for the healthcare industry

Thanks to its compliance with ASTM F138 and ISO 5832-1 standards, 316LVM is a trusted material in the global biomedical sector.

| What is 316LVM Stainless Steel? |

316LVM stainless steel is a vacuum-melted, low-carbon version of 316L stainless steel, specifically designed for medical and surgical applications. The “VM” stands for Vacuum Melted, referring to the refining process that removes impurities and ensures exceptional cleanliness and consistency. This alloy is also known by its ASTM F138 designation, which certifies its use for biomedical implants and instruments.

| FAQ |

Q1: What does 316LVM stand for?

A1: 316LVM stands for 316L Vacuum Melted stainless steel, a medical-grade version of 316L with ultra-low impurity levels, offering superior biocompatibility.

Q2: Is 316LVM magnetic?

A2: No, 316LVM is non-magnetic in the annealed condition, making it ideal for surgical and diagnostic environments.

Q3: What is the difference between 316L and 316LVM?

A3: 316LVM is produced under vacuum melting conditions, ensuring higher purity and corrosion resistance compared to standard 316L.

Q4: Can 316LVM be used for implants?

A4: Yes, 316LVM is certified for implant-grade applications under ASTM F138 and ISO 5832-1 standards.

| Why Choose SAKYSTEEL : |

Reliable Quality – Our stainless steel bars, pipes, coils, and flanges are manufactured to meet international standards such as ASTM, AISI, EN, and JIS.

Strict Inspection – Every product undergoes ultrasonic testing, chemical analysis, and dimensional control to ensure high performance and traceability.

Strong Stock & Fast Delivery – We maintain regular inventory of key products to support urgent orders and global shipping.

Customized Solutions – From heat treatment to surface finish, SAKYSTEEL offers tailor-made options to match your exact requirements.

Professional Team – With years of export experience, our sales and technical support team ensures smooth communication, quick quotations, and full documentation service.

| SAKY STEEL’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,