AISI 4340 Alloy Steel Flat Bar | High Strength Low Alloy Steel Supplier

Short Description:

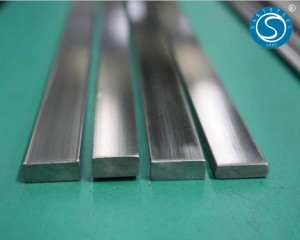

AISI 4340 Alloy Steel Flat Bar is a premium-grade, low-alloy steel renowned for its superior toughness, high tensile strength, and excellent wear resistance. Containing nickel, chromium, and molybdenum, this steel grade is ideal for applications requiring high fatigue strength and impact resistance.

4340 Alloy Steel Flat Bar:

AISI 4340 Alloy Steel Flat Bar is a high-strength, low-alloy steel flat product renowned for its excellent toughness, deep hardenability, and resistance to wear and fatigue. Commonly known as 34CrNiMo6, 1.6582, or 817M40 in international standards, this alloy contains nickel, chromium, and molybdenum, making it ideal for heavy-duty applications. It is widely used in the aerospace, automotive, and military industries for manufacturing crankshafts, axles, gear components, and structural parts requiring high impact resistance and long service life.

Specifications Of 4340 Flat Bar:

| Specifications | ASTM A29 |

| Grade | 4340,G43400 |

| Length | As Required |

| Thickness | 2mm-100mm |

| Condition | Hot rolled,Smooth turned,Peeled,Cold Drawn,Centreless Ground,Polished |

| Surface Finish | Black, Polished |

Alloy Steel 4340 Bar Equivalent Grades:

| STANDARD | WERKSTOFF NR. | UNS |

| 4340 | 1.6565 | G43400 |

4340 Steel Flat Rod Chemical Composition:

| Grade | C | Mn | Si | Cr | Ni | Mo |

| 4340 | 0.38-0.43 | 0.60-0.80 | 0.15-0.30 | 0.70-0.90 | 1.65-2.0 | 0.20-0.30 |

Mechanical properties :

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Hardness |

| 850-1000MPa | 680-860MPa | 14 % | 24-28HRC |

4340 Steel Bar UT Test :

Our 4340 alloy steel flat bars undergo rigorous ultrasonic testing (UT) to ensure internal soundness and defect-free structure. This non-destructive testing method detects internal discontinuities such as cracks, voids, and inclusions that are invisible to the naked eye. UT inspection is conducted in accordance with industry standards, ensuring each bar meets high-performance requirements for aerospace, automotive, and heavy-duty engineering applications. Reliable quality control guarantees enhanced fatigue resistance, structural integrity, and customer confidence.

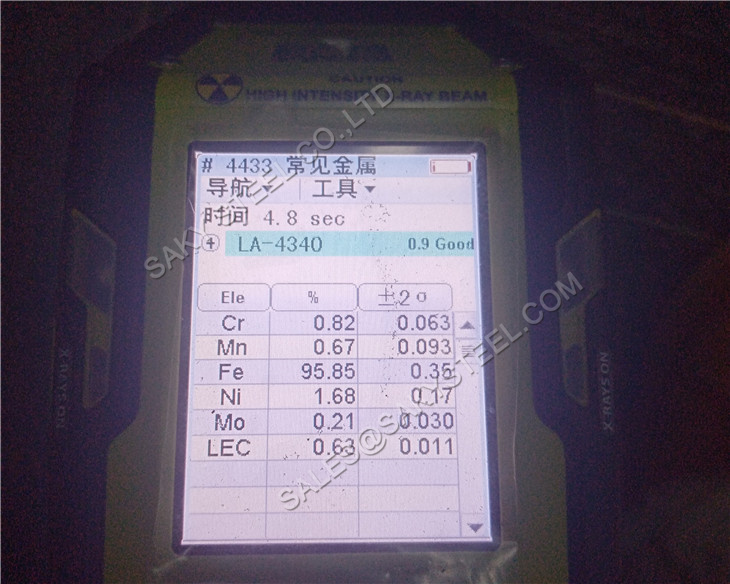

4340 Alloy Bar PMI Test :

To ensure material traceability and compliance with customer specifications, PMI (Positive Material Identification) testing is conducted on AISI 4340 Alloy Steel Flat Bars using advanced spectrometers or X-ray fluorescence (XRF) analyzers. This non-destructive testing method verifies the chemical composition of each heat number, ensuring it meets the required alloying element ranges such as Ni, Cr, and Mo.

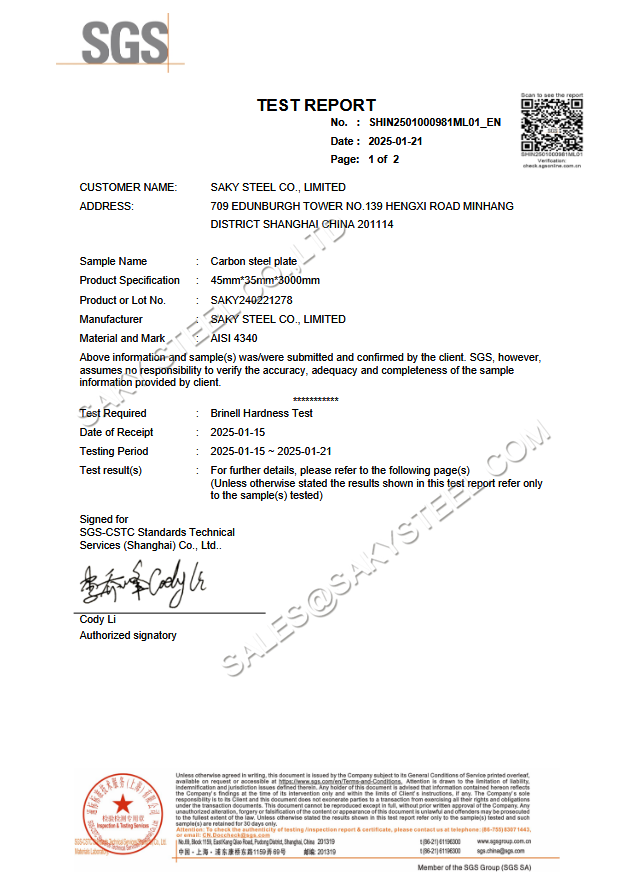

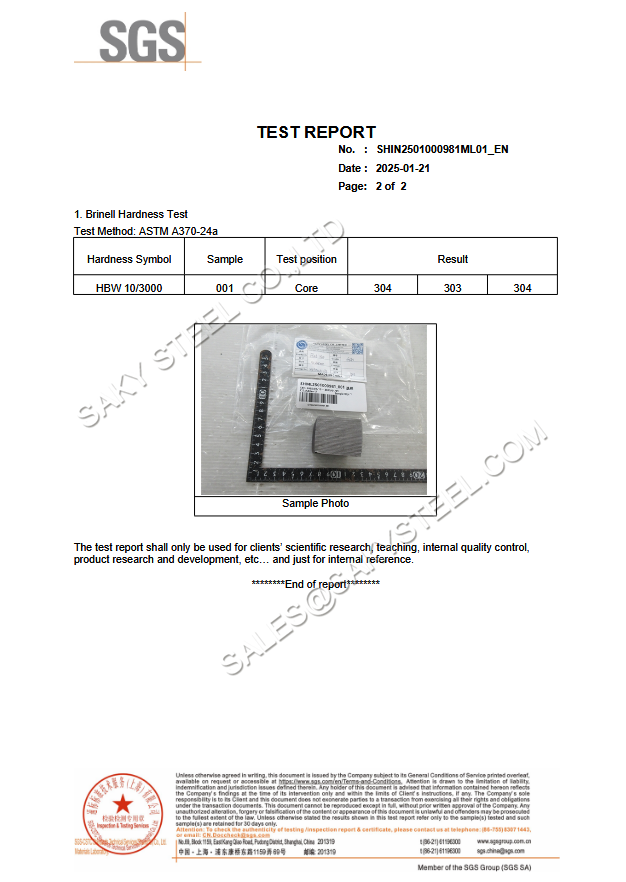

4340 Bar Hardness Test :

To confirm the heat treatment condition and verify mechanical performance, hardness testing is conducted on AISI 4340 Alloy Steel Flat Bars using Rockwell or Brinell methods. For quenched and tempered bars, the typical hardness range is 24 to 38 HRC. Hardness values are recorded at multiple locations across the surface and cross-section to ensure uniformity. The results help confirm the steel’s suitability for demanding applications involving high stress and impact.

Applications of AISI 4340 Alloy Bar

1.Aircraft Landing Gear Assemblies:

Widely employed in manufacturing landing gear components such as struts and linkages, where its superior tensile strength and resilience ensure dependable performance under extreme stress.

2.Automotive Drivetrain Systems:

Used in the production of critical transmission parts like gears and shafts, AISI 4340 delivers outstanding durability and operational efficiency in high-load automotive environments.

3.Forged Hydraulic System Parts:

Chosen for hydraulic system applications, this alloy excels in withstanding pressure and mechanical shock, making it ideal for forged hydraulic pistons, cylinders, and fittings.

4.High-Performance Engine Crankshafts:

Favored for crankshaft fabrication in high-performance engines, its exceptional fatigue strength and toughness ensure long service life under cyclic loading.

5.Industrial Power Transmission Components:

Applied in the construction of heavy-duty gears and shafts for power transmission equipment, where it resists wear and deformation in demanding mechanical systems.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

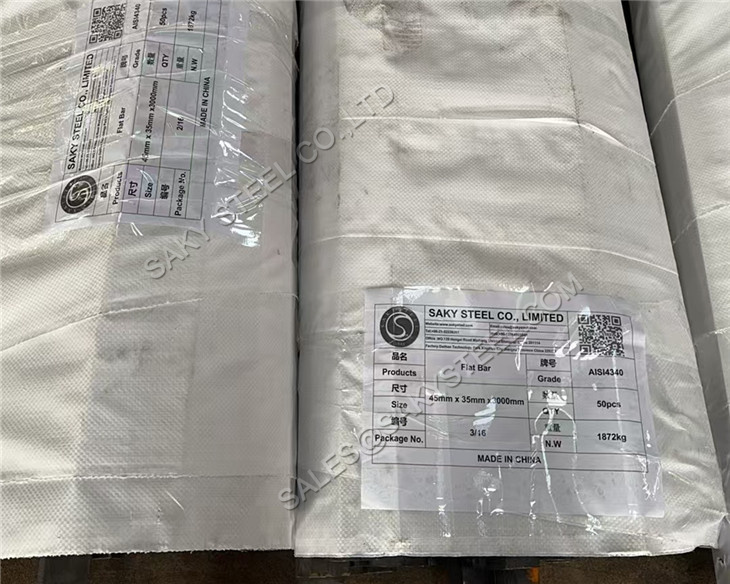

High Tensile Steel Flat 4340 Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,