I-beams, also known as H-beams, play a crucial role in the realm of structural engineering and construction. These beams derive their name from their distinctive I or H-shaped cross-section, featuring horizontal elements known as flanges and a vertical element referred to as the web. This article aims to delve into the characteristics, applications, and significance of I-beams in various construction projects.

Ⅰ.Types of I-beams:

Various types of I-beams exhibit subtle differences in their characteristics, including H-piles, Universal Beams (UB), W-beams, and Wide Flange Beams. Despite sharing an I-shaped cross-section, each type has unique features that cater to specific structural requirements.

1. I-Beams:

•Parallel Flanges: I-beams have parallel flanges, and in some instances, these flanges may taper.

•Narrow Legs: The legs of I-beams are narrower compared to H-piles and W-beams.

•Weight Tolerance: Due to their narrower legs, I-beams can tolerate less weight and are typically available in shorter lengths, up to 100 feet.

•S-Beam Type: I-beams fall under the category of S beams.

2. H-Piles:

•Heavy Design: Also known as bearing piles, H-piles closely resemble I-beams but are heavier.

•Wide Legs: H-piles have wider legs than I-beams, contributing to their increased weight-bearing capacity.

•Equal Thickness: H-piles are designed with equal thicknesses across all sections of the beam.

•Wide Flange Beam Type: H-piles are a type of wide flange beam.

3. W-Beams / Wide Flange Beams:

•Wider Legs: Similar to H-piles, W-beams feature wider legs than standard I-beams.

•Varying Thickness: Unlike H-piles, W-beams do not necessarily have equal web and flange thicknesses.

•Wide Flange Beam Type: W-beams fall into the category of wide flange beams.

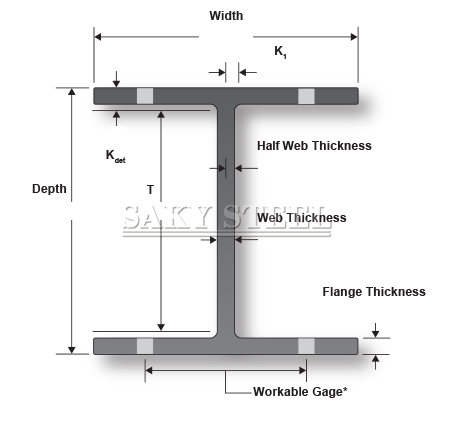

Ⅱ. Anatomy of an I-Beam:

The structure of an I-beam is composed of two flanges connected by a web. The flanges are the horizontal components that bear the majority of the bending moment, while the web, situated vertically between the flanges, resists shear forces. This unique design imparts significant strength to the I-beam, making it an ideal choice for various structural applications.

Ⅲ. Materials and Manufacturing:

I-beams are commonly manufactured from structural steel due to its exceptional strength and durability. The manufacturing process involves shaping the steel into the desired I-shaped cross-section through hot rolling or welding techniques. Additionally, I-beams can be crafted from other materials such as aluminum to meet specific project requirements.

Post time: Jan-31-2024