Stainless Steel H I Beam

Short Description:

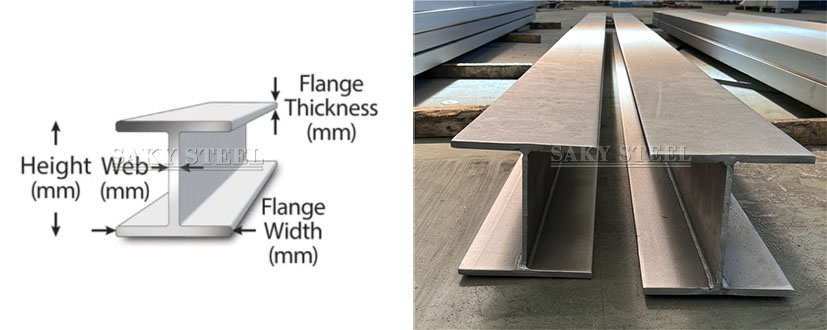

“H Beam” refer to structural components shaped like the letter “H” that are commonly used in construction and various structural applications.

Stainless Steel H Beam:

Stainless steel H Beam are structural components characterized by their H-shaped cross-section. These channels are crafted from stainless steel, a corrosion-resistant alloy known for its durability, hygiene, and aesthetic appeal. Stainless steel H channels find applications in various industries, including construction, architecture, and manufacturing, where their corrosion resistance and strength make them a preferred choice for structural support and design.These components are often used in the construction of frameworks, supports, and other structural elements where both strength and a polished appearance are essential.

Specifications Of I Beam:

| Grade | 302 304 304L 310 316 316L 321 2205 2507 etc. |

| Standard | GB T33814-2017,GBT11263-2017 |

| Surface | Sandblasting, polishing, shot blasting |

| Technology | Hot Rolled , Welded |

| Length | 1 to 12 Meters |

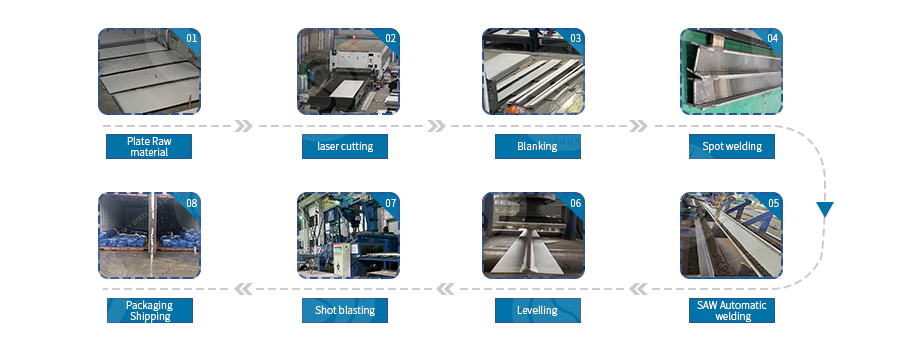

I-beam production flow chart:

Web:

The web serves as the central core of the beam, typically graded based on its thickness. Functioning as the structural link, it plays a crucial role in preserving the beam's integrity by connecting and uniting the two flanges, effectively distributing and managing pressure.

Flange:

The upper and flat lower sections of steel bear the primary load. To ensure uniform pressure distribution, we flatten the flanges. These two components run parallel to each other, and in the context of I-beams, they feature wing-like extensions.

H Beam Welded Line thickness Measurement:

Stainless Steel I Beam Beveling Process:

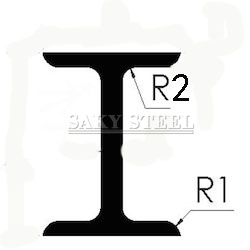

The R angle of I-beam is polished to make the surface smooth and burr-free, which is convenient for protecting the safety of personnel. We can process the R angle of 1.0, 2.0, 3.0. 304 316 316L 2205 Stainless Steel I H Beams. The R angles of the 8 lines are all polished.

Stainless Steel I Beam Wing/Flange straighting:

Features & Benefits:

• The "H"-shaped cross-section design of I-beam steel provides outstanding load-bearing capacity for both vertical and horizontal loads.

• The structural design of I-beam steel imparts a high level of stability, preventing deformation or bending under stress.

• Due to its unique shape, I-beam steel can be flexibly applied to various structures, including beams, columns, bridges, and more.

• I-beam steel performs exceptionally well in bending and compression, ensuring stability under complex loading conditions.

• With its efficient design and superior strength, I-beam steel often offers good cost-effectiveness.

• I-beam steel finds extensive use in construction, bridges, industrial equipment, and various other fields, showcasing its versatility across different engineering and structural projects.

• The design of I-beam steel allows it to better adapt to the requirements of sustainable construction and design, providing a viable structural solution for environmental-friendly and green building practices.

Chemical Composition H Beam:

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo | Nitrogen |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | - | - |

| 309 | 0.20 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | - | - |

| 310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 314 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - |

Mechanical properties Of I Beams:

| Grade | Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 95[665] | 45[310] | 28 |

| 309 | 75[515] | 30[205] | 40 |

| 310 | 75[515] | 30[205] | 40 |

| 314 | 75[515] | 30[205] | 40 |

| 316 | 95[665] | 45[310] | 28 |

| 321 | 75[515] | 30[205] | 40 |

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

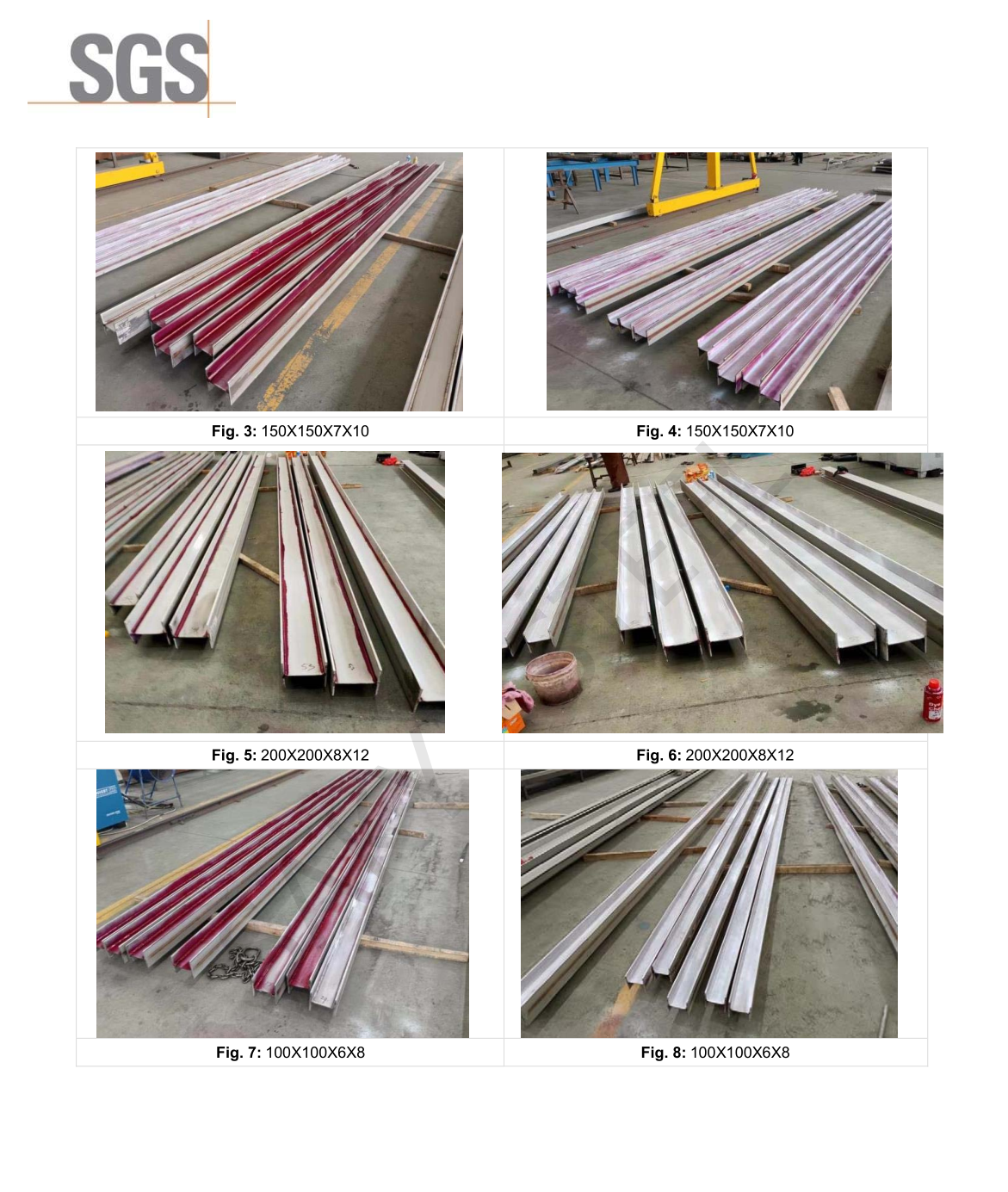

316L stainless steel welded H Beam Penetration test (PT)

Base on JBT 6062-2007 Non-destructive testing - penetrant testing of welds for 304L 316L stainless steel welded H Beam.

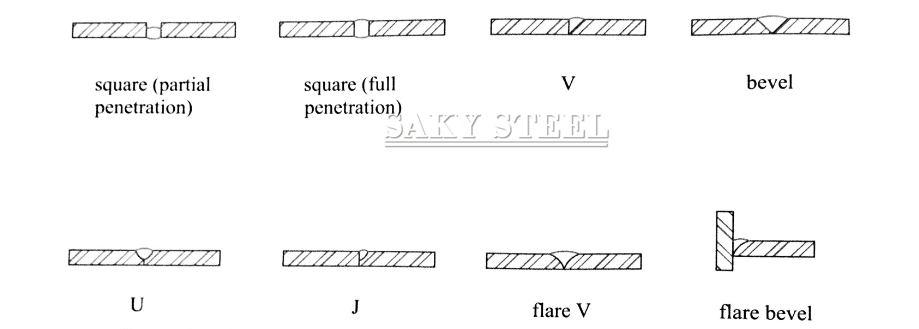

What are the welding methods?

Welding methods include arc welding, gas shielded welding (MIG/MAG welding), resistance welding, laser welding, plasma arc welding, friction stir welding, pressure welding, electron beam welding, etc. Each method has unique applications and characteristics, suitable for different types of workpieces and production requirements.An arc is used to generate high temperatures, melting the metal on the surface of the workpiece to form a connection. Common arc welding methods include manual arc welding, argon arc welding, submerged arc welding, etc.The heat generated by the resistance is used to melt the metal on the surface of the workpiece to form a connection. Resistance welding includes spot welding, seam welding and bolt welding.

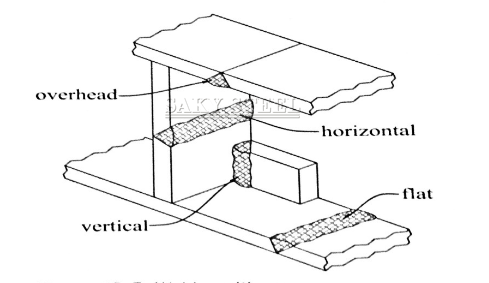

Whenever possible, welds should be performed in the shop where the quality of theweld is usually better, Shop welds are not subjected to the weather and access to thejoint is fairly open. Welds can be classified as flat, horizontal, vertical, and overhead. It can be seen that flat welds are the easiest to perform; they are thepreferred method. Overhead welds, which are usually done in the field, should also beavoided where possible because they are difficult and more time-consuming, and there.fore more costly.

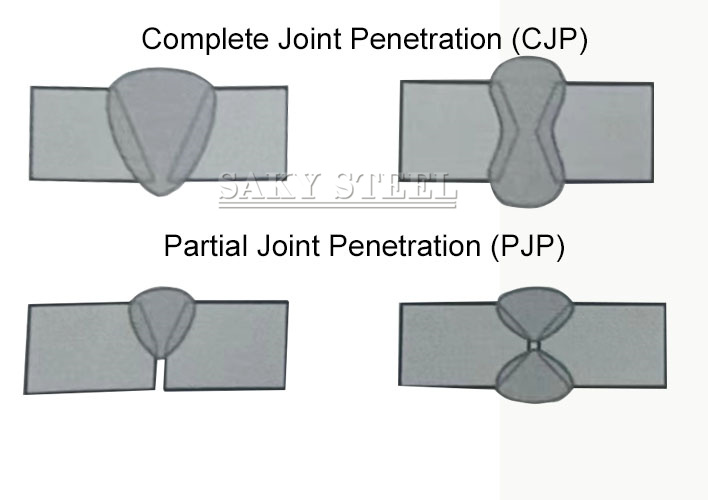

Groove welds can penetrate the connected member for a portion of the member thickness, or it can penetrate the full thickness of the connected member. These are called partialjoint penetration (PJP) and complete-joint penetration (CJP), respectively . Complete-penetration welds (also called full.penetration or “'full-pen” welds) fuse the entire depth of the ends of the connected membersPartial penetration welds are more cost-effective and are used when the applied loads are suchthat a full-penetration weld is not required. They can also be used where access to the grooveis limited to one side of the connection.

Note: Index STRUCTURAL STEEL DESIGN

What are the advantages of submerged arc welding?

Submerged arc welding is suitable for automation and high-volume environments. It can complete a large amount of welding work in a relatively short period of time and improve production efficiency. Submerged arc welding is suitable for automation and high-volume environments. It can complete a large amount of welding work in a relatively short period of time and improve production efficiency. Submerged arc welding is typically used to weld thicker metal sheets because its high current and high penetration make it more effective in these applications. Since the weld is covered by flux, oxygen can be effectively prevented from entering the weld area, thereby reducing the possibility of oxidation and spatter.Compared to some manual welding methods, submerged arc welding can often be automated more easily, reducing the high demands on worker skills. In submerged arc welding, multiple welding wires and arcs can be used simultaneously to achieve multi-channel (multi-layer) welding and improve efficiency.

What are the applications of Stainless Steel H beams?

Stainless steel H beams are widely utilized in construction, marine engineering, industrial equipment, automotive, energy projects, and other fields due to their corrosion resistance and durability. They provide structural support in construction projects and play a crucial role in environments requiring corrosion resistance, such as marine or industrial settings. Additionally, their modern and aesthetic appearance makes them suitable for architectural and interior design applications.

How straight is Stainless Steel H I beam?

The straightness of a stainless steel H-beam, like any structural component, is an important factor in its performance and installation. In general, manufacturers produce stainless steel H-beams with a certain degree of straightness to meet industry standards and specifications.

The accepted industry standard for straightness in structural steel, including stainless steel H-beams, is often defined in terms of allowable deviations from a straight line over a specified length. This deviation is typically expressed in terms of millimeters or inches of sweep or lateral displacement.

Introduction to the shape of H beam ?

The cross-sectional shape of I-beam steel, commonly known as "工字钢" (gōngzìgāng) in Chinese, resembles the letter "H" when opened. Specifically, the cross-section typically consists of two horizontal bars (flanges) at the top and bottom and a vertical middle bar (web). This "H" shape imparts superior strength and stability to I-beam steel, making it a common structural material in construction and engineering.The designed shape of I-beam steel allows it to be suitable for various load-bearing and support applications, such as beams, columns, and bridge structures. This structural configuration enables I-beam steel to effectively distribute loads when subjected to forces, providing robust support. Due to its unique shape and structural characteristics, I-beam steel finds widespread use in the fields of construction and engineering.

How to express the size and expression of I-beam?

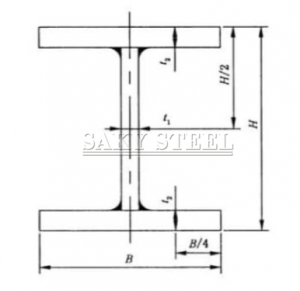

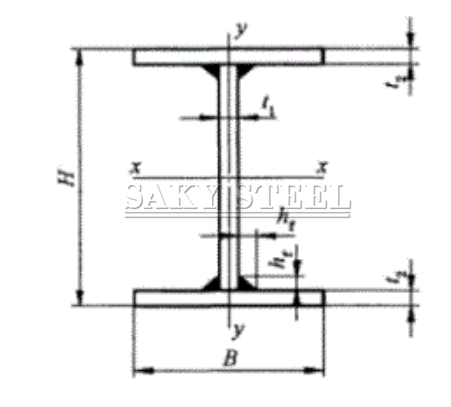

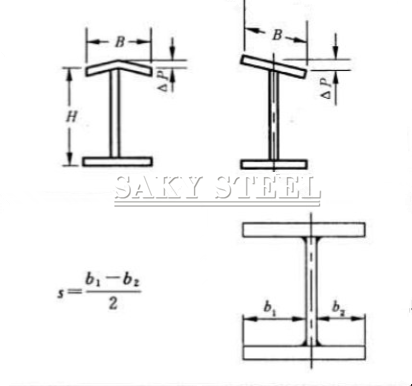

Ⅰ.Cross-sectional illustration and marking symbols of 316L stainless steel welded H-shaped steel:

H——Height

B——Width

t1——Web thickness

t2——Flange plate thickness

h£——Welding size(when using a combination of butt and fillet welds, it should be the reinforced welding leg size hk)

Ⅱ. Dimensions, shapes and allowable deviations of 2205 duplex steel welded H-shaped steel:

| H Beam | Tolerance |

| Thlckness (H) | Helght 300 or less: 2.0 mmMore than 300:3.0mm |

| Width (B) | 士2.0mm |

| Perpendicularlty (T) | 1.2% or less of wldth (B)Note that minlmum toleranceis 2.0 mm |

| Offset of center (C) | 士2.0mm |

| Bending | 0.2096 or less of length |

| Leg length (S) | [web plate thlckness (t1) x0.7]or more |

| Length | 3~12m |

| Length tolerance | +40mm,一0mm |

Ⅲ. Dimensions, shapes and allowable deviations of welded H-shaped steel

Ⅳ. Cross-sectional dimensions, cross-sectional area, theoretical weight and cross-sectional characteristic parameters of welded H-shaped steel

| Stainless steel Beams | Size | Sectional Area(cm²) | Weight

(kg/m) |

Characteristic Parameters | Weld fillet size h(mm) | ||||||||

| H | B | t1 | t2 | x-x | y-y | ||||||||

| mm | I | W | i | I | W | i | |||||||

| WH100X50 | 100 | 50 | 3.2 | 4.5 | 7.41 | 5.2 | 123 | 25 | 4.07 | 9 | 4 | 1.13 | 3 |

| 100 | 50 | 4 | 5 | 8.60 | 6.75 | 137 | 27 | 3.99 | 10 | 4 | 1.10 | 4 | |

| WH100X100 | 100 | 100 | 4 | 6 | 15.52 | 12.18 | 288 | 58 | 4.31 | 100 | 20 | 2.54 | 4 |

| 100 | 100 | 6 | 8 | 21.04 | 16.52 | 369 | 74 | 4.19 | 133 | 27 | 2.52 | 5 | |

| WH100X75 | 100 | 75 | 4 | 6 | 12.52 | 9.83 | 222 | 44 | 4.21 | 42 | 11 | 1.84 | 4 |

| WH125X75 | 125 | 75 | 4 | 6 | 13.52 | 10.61 | 367 | 59 | 5.21 | 42 | 11 | 1.77 | 4 |

| WH125X125 | 125 | 75 | 4 | 6 | 19.52 | 15.32 | 580 | 93 | 5.45 | 195 | 31 | 3.16 | 4 |

| WH150X75 | 150 | 125 | 3.2 | 4.5 | 11.26 | 8.84 | 432 | 58 | 6.19 | 32 | 8 | 1.68 | 3 |

| 150 | 75 | 4 | 6 | 14.52 | 11.4 | 554 | 74 | 6.18 | 42 | 11 | 1.71 | 4 | |

| 150 | 75 | 5 | 8 | 18.70 | 14.68 | 706 | 94 | 6.14 | 56 | 15 | 1.74 | 5 | |

| WH150X100 | 150 | 100 | 3.2 | 4.5 | 13.51 | 10.61 | 551 | 73 | 6.39 | 75 | 15 | 2.36 | 3 |

| 150 | 100 | 4 | 6 | 17.52 | 13.75 | 710 | 95 | 6.37 | 100 | 20 | 2.39 | 4 | |

| 150 | 100 | 5 | 8 | 22.70 | 17,82 | 908 | 121 | 6.32 | 133 | 27 | 2.42 | 5 | |

| WH150X150 | 150 | 150 | 4 | 6 | 23.52 | 18.46 | 1 021 | 136 | 6,59 | 338 | 45 | 3.79 | 4 |

| 150 | 150 | 5 | 8 | 30.70 | 24.10 | 1 311 | 175 | 6.54 | 450 | 60 | 3.83 | 5 | |

| 150 | 150 | 6 | 8 | 32.04 | 25,15 | 1 331 | 178 | 6.45 | 450 | 60 | 3.75 | 5 | |

| WH200X100 | 200 | 100 | 3.2 | 4.5 | 15.11 | 11.86 | 1 046 | 105 | 8.32 | 75 | 15 | 2.23 | 3 |

| 200 | 100 | 4 | 6 | 19.52 | 15.32 | 1 351 | 135 | 8.32 | 100 | 20 | 2.26 | 4 | |

| 200 | 100 | 5 | 8 | 25.20 | 19.78 | 1 735 | 173 | 8.30 | 134 | 27 | 2.30 | 5 | |

| WH200X150 | 200 | 150 | 4 | 6 | 25.52 | 20.03 | 1 916 | 192 | 8.66 | 338 | 45 | 3.64 | 4 |

| 200 | 150 | 5 | 8 | 33.20 | 26.06 | 2 473 | 247 | 8.63 | 450 | 60 | 3.68 | 5 | |

| WH200X200 | 200 | 200 | 5 | 8 | 41.20 | 32.34 | 3 210 | 321 | 8.83 | 1067 | 107 | 5.09 | 5 |

| 200 | 200 | 6 | 10 | 50.80 | 39.88 | 3 905 | 390 | 8.77 | 1 334 | 133 | 5,12 | 5 | |

| WH250X125 | 250 | 125 | 4 | 6 | 24.52 | 19.25 | 2 682 | 215 | 10.46 | 195 | 31 | 2.82 | 4 |

| 250 | 125 | 5 | 8 | 31.70 | 24.88 | 3 463 | 277 | 10.45 | 261 | 42 | 2.87 | 5 | |

| 250 | 125 | 6 | 10 | 38.80 | 30.46 | 4210 | 337 | 10.42 | 326 | 52 | 2.90 | 5 | |

Our Clients

Feedbacks From Our Clients

Stainless Steel H Beams are versatile structural components crafted from high-quality stainless steel. These channels feature a distinctive "H" shape, providing enhanced strength and stability to various construction and architectural applications.The sleek and polished finish of stainless steel adds a touch of sophistication, making these H Beam suitable for both functional and visually appealing design elements.The H-shaped design maximizes load-bearing capacity, making these channels ideal for supporting heavy loads in construction and industrial settings.Stainless Steel H Beams find applications in various industries, including construction, architecture, and manufacturing, where robust structural support is essential.

Stainless Steel I Beams Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,