Kuʻikuʻi HI

ʻO ka wehewehe pōkole:

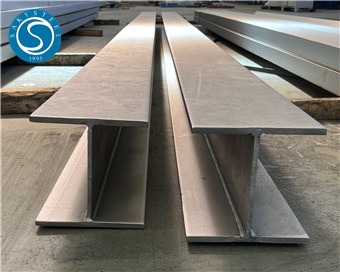

ʻO ka "H Beam" e pili ana i nā mea hana i hoʻohālikelike ʻia e like me ka huapalapala "H" i hoʻohana mau ʻia i ke kūkulu ʻana a me nā noi hoʻolālā like ʻole.

ʻO ke kila kila H:

ʻO ke kila kila H Beam nā mea hana i hōʻike ʻia e ko lākou ʻāpana ʻāpana H-like. Hana ʻia kēia mau kahawai mai ke kila kila, kahi huila pale ʻino i ʻike ʻia no kona lōʻihi, maʻemaʻe, a me ka hoʻopiʻi nani. Hiki ke hoʻohana ʻia nā ala hao H i nā noi i nā ʻoihana like ʻole, e like me ke kūkulu ʻana, ka hale hana, a me ka hana ʻana, kahi e hoʻolilo ai ko lākou kūpaʻa ʻana a me ka ikaika iā lākou i koho maikaʻi ʻia no ke kākoʻo a me ka hoʻolālā.

Nā kikoʻī o I Beam:

| Papa | 302 304 304L 310 316 316L 321 2205 2507 etc. |

| Kūlana | GB T33814-2017, GBT11263-2017 |

| Ili | Sandblasting, polishing, pana pana |

| ʻenehana | Hoʻowili wela , Weled |

| Ka lōʻihi | 1 a 12 mika |

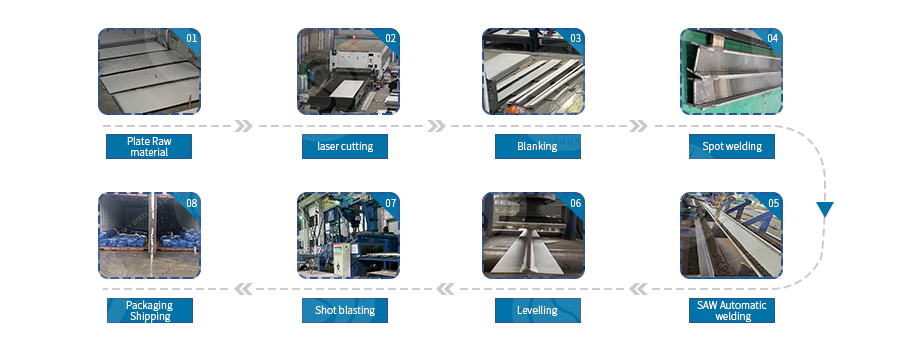

I-beam production flow chart:

Pūnaewele:

ʻO ka pūnaewele ma ke ʻano he kikowaena o ka lāʻau, e helu ʻia ma muli o kona mānoanoa. Ke hana nei ʻo ia ma ke ʻano he loulou, he kuleana koʻikoʻi ia i ka mālama ʻana i ka kūpaʻa o ka beam ma o ka hoʻopili ʻana a me ka hoʻohui ʻana i nā flanges ʻelua, ka hāʻawi pono ʻana a me ka mālama ʻana i ke kaomi.

Flange:

ʻO nā ʻāpana o luna a me ka papa haʻahaʻa o ke kila ke amo i ka ukana mua. No ka hōʻoia ʻana i ka puʻunaue like ʻole, hoʻopalahalaha mākou i nā flanges. Holo like kēia mau ʻāpana ʻelua i kekahi i kekahi, a i ka pōʻaiapili o nā I-beams, hōʻike lākou i nā hoʻonui e like me nā ʻēheu.

H Beam Welded Line mānoanoa ana:

ʻO ke kaʻina hana Beveling Steel I Beam Beveling:

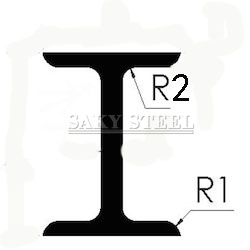

Hoʻopili ʻia ke kihi R o I-beam e hoʻomaʻemaʻe i ka ʻili a me ka burr-free, kahi kūpono no ka pale ʻana i ka palekana o nā limahana. Hiki iā mākou ke hana i ka huina R o 1.0, 2.0, 3.0. 304 316 316L 2205 Na Kuola IH Kuhiliʻole. ʻO nā ʻaoʻao R o nā laina 8 ua pau i ka poli.

ʻEheu ʻēheu/Flange hoʻopololei:

Nā hiʻohiʻona a me nā pono:

•ʻO ka hoʻolālā ʻāpana ʻāpana "H" o ke kila I-beam e hāʻawi i ka hiki ke amo i nā haʻahaʻa koʻikoʻi no nā haʻahaʻa kū a me ka pae.

•ʻO ka hoʻolālā hoʻolālā o ke kila I-beam e hāʻawi i kahi kiʻekiʻe o ke kūpaʻa, pale i ka deformation a i ʻole ke kulou ʻana ma lalo o ke kaumaha.

•Ma muli o kona ʻano ʻano like ʻole, hiki ke hoʻohana maʻalahi ʻia ke kila I-beam i nā hale like ʻole, me nā kaola, nā kolamu, nā alahaka, a me nā mea hou aku.

•Hana maikaʻi loa ke kila I-beam i ka piko a me ka hoʻopaʻa ʻana, e hōʻoia ana i ka paʻa ma lalo o nā kūlana hoʻouka paʻakikī.

•Me kona hoʻolālā maikaʻi a me ka ikaika kiʻekiʻe, hāʻawi pinepine ka I-beam steel i ka maikaʻi kumu kūʻai.

•Loaʻa i ka I-beam steel ka hoʻohana nui ʻana i ke kūkulu ʻana, nā alahaka, nā mea hana ʻoihana, a me nā ʻano ʻano ʻē aʻe, e hōʻike ana i kona versatility ma nā ʻenehana like ʻole a me nā papahana hoʻolālā.

•ʻO ka hoʻolālāʻana o ka I-beam steel e hiki ai iā ia ke hoʻololi maikaʻi i nā koi o ke kūkulu paʻa a me ka hoʻolālā, e hāʻawi ana i kahi hoʻonā kūpono kūpono no nā hana hale a me ka'ōmaʻomaʻo.

Hoʻohui Kimia H Beam:

| Papa | C | Mn | P | S | Si | Cr | Ni | Mo | Nitrogen |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | - | - |

| 309 | 0.20 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | - | - |

| 310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 314 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - |

Mechanical waiwai o I kaola:

| Papa | Ka ikaika uʻi ksi[MPa] | Huakaʻi ikaika ksi[MPa] | Elongation % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 95[665] | 45[310] | 28 |

| 309 | 75[515] | 30[205] | 40 |

| 310 | 75[515] | 30[205] | 40 |

| 314 | 75[515] | 30[205] | 40 |

| 316 | 95[665] | 45[310] | 28 |

| 321 | 75[515] | 30[205] | 40 |

No ke aha e koho ai iā mākou?

•Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

•Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka i ka puka. Manaʻo mākou iā ʻoe e hana i ka hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

•Hiki ke hōʻoia ʻia nā mea a mākou e hāʻawi ai, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope. (E hōʻike ʻia nā hōʻike ma ke koi)

•Ke hōʻoiaʻiʻo nei mākou e hāʻawi i kahi pane i loko o 24 mau hola (maʻamau i ka hola hoʻokahi)

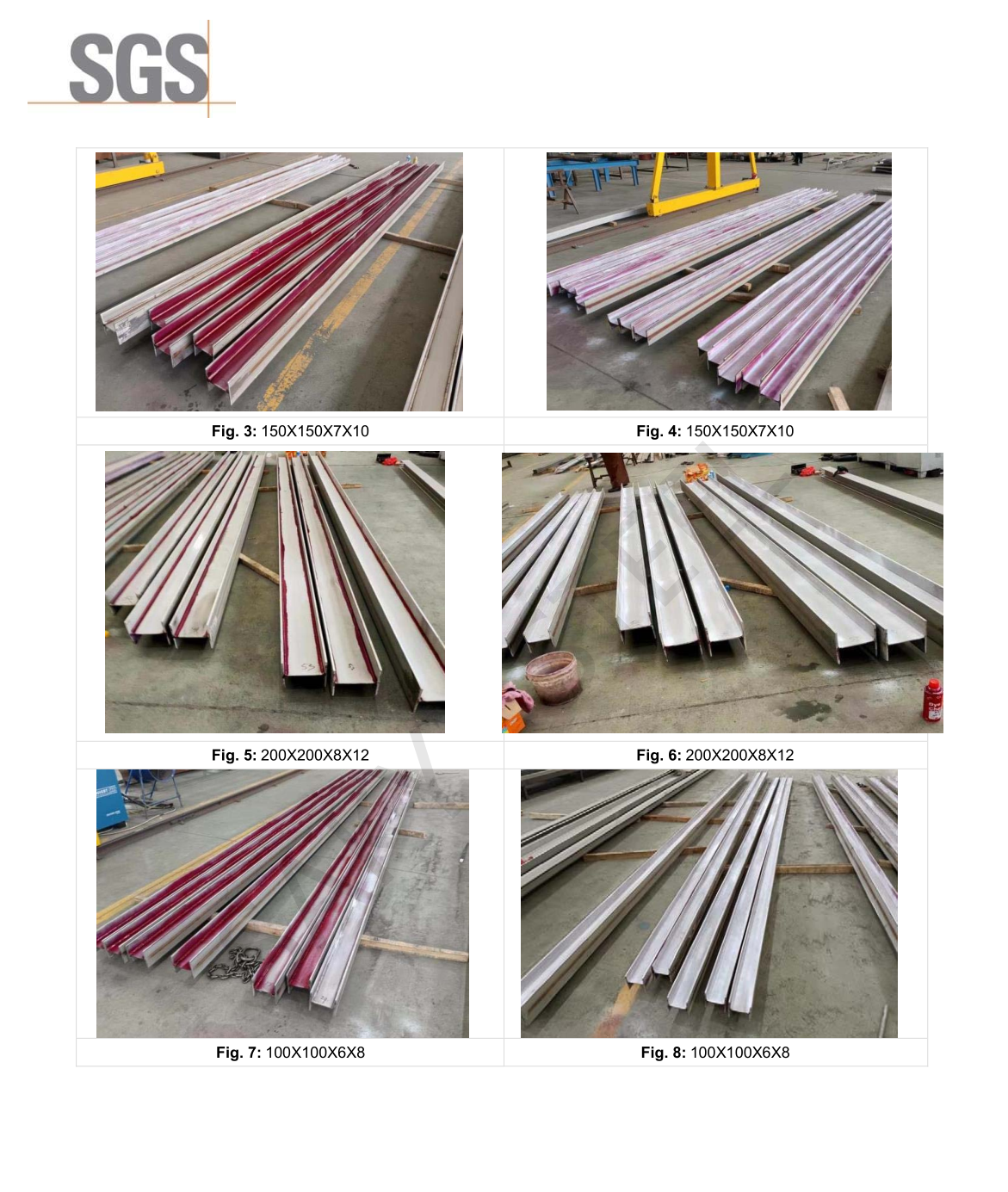

•Hāʻawi i ka hōʻike SGS TUV.

•Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

•Hāʻawi i ka lawelawe hoʻokahi.

316L kila kuhiliʻole wili ʻia ʻo H Beam Penetration test (PT)

Base ma JBT 6062-2007 Non-destructive ho'āʻo - penetrant ho'āʻo o welds no 304L 316L kuhiliʻole kila welded H Beam.

He aha nā ʻano hana wili?

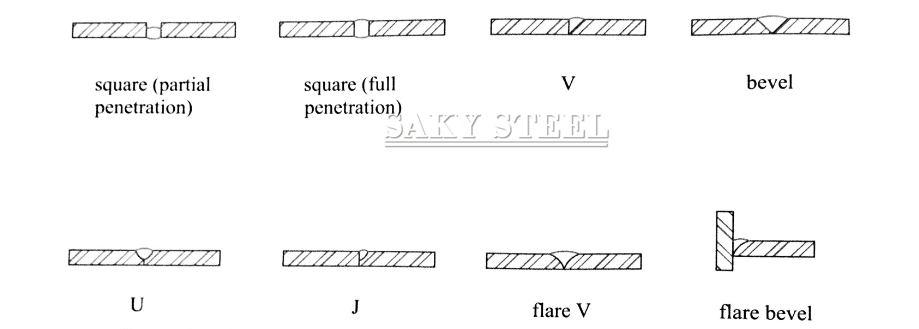

ʻO nā ʻano hana hoʻoheheʻe ʻia ʻo ia ka welding arc, welding pale kinoea (MIG/MAG welding), welding resistance, laser welding, plasma arc welding, friction stir welding, pressure welding, electron beam welding, a pēlā aku. ʻO nāʻano hana hoʻoheheʻe arc maʻamau,ʻo ia hoʻi ka hoʻoheheʻe manual arc, argon arc welding, submerged arc welding, etc.ʻO ka wela i hanaʻia e ke kū'ē i hoʻohanaʻia e hoʻoheheʻe i ka metala ma kaʻili o ka mea hana e hana i kahi pilina. ʻO ke kuʻi kūʻē ʻana e pili ana i ka wiliwili kiko, wili wili a me ka wili bolt.

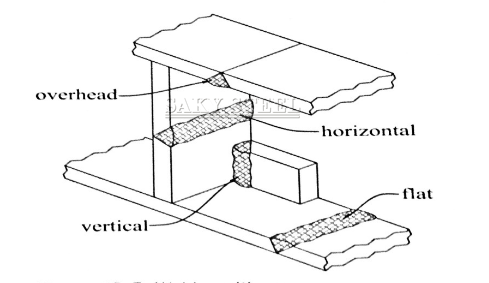

I nā manawa e hiki ai, pono e hana ʻia nā welds i loko o ka hale kūʻai kahi i ʻoi aku ka maikaʻi o ka weld, ʻaʻole i kau ʻia nā welds Shop i ka wā a ua wehe ʻia ke komo ʻana i ka hui. Hiki ke hoʻokaʻawale ʻia nā welds ma ke ʻano he pālahalaha, ākea, kūpaʻa, a me ke poʻo. Hiki ke ʻike ʻia ʻo nā welds palahalaha ka mea maʻalahi loa e hana; ʻo lākou ke ala i makemake ʻia. ʻO nā welds ma luna o ke poʻo, ka mea maʻamau i hana ʻia ma ke kula, pono e ʻalo ʻia i kahi hiki no ka mea paʻakikī a ʻoi aku ka manawa, a laila ʻoi aku ka uku.

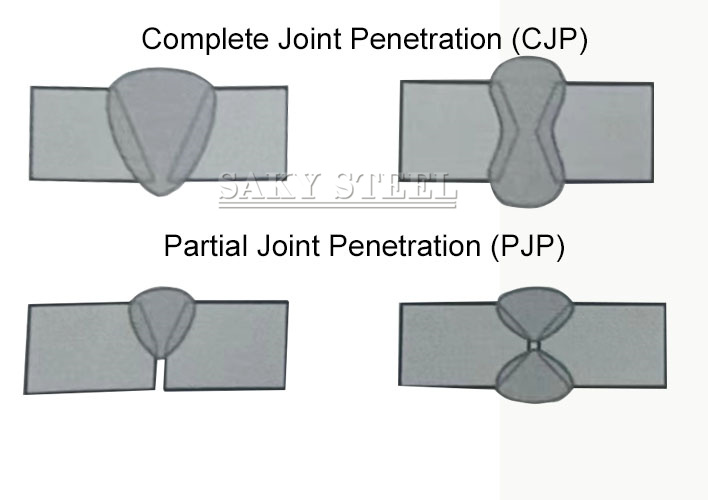

Hiki i nā welds groove ke komo i ka lālā pili no kahi hapa o ka mānoanoa lālā, a i ʻole hiki ke komo i ka mānoanoa piha o ka lālā pili. Ua kapa ʻia kēia mau mea ʻo partialjoint penetration (PJP) a me ka hui pū piha (CJP), kēlā me kēia. ʻO nā welds komo piha (i kapa ʻia ʻo full.penetration a i ʻole "'full-pen" welds) hoʻohui i ka hohonu holoʻokoʻa o nā wēlau o nā lālā i hoʻopili ʻia ʻoi aku ka maikaʻi o nā weld komo ʻāpana a hoʻohana ʻia ke hoʻohana ʻia nā ukana i hoʻopili ʻia ʻaʻole koi ʻia kahi weld komo piha. Hiki ke hoʻohana ʻia ma kahi e hiki ai ke komo i ka groove i kaupalena ʻia i kekahi ʻaoʻao o ka pilina.

'Ōlelo Aʻo: Index STRUCTURAL STEEL DESIGN

He aha nā mea maikaʻi o ka hoʻoheheʻe ʻana i ka arc submerged?

He kūpono ke kuʻekuʻe wāwae i lalo no ka automation a me nā wahi kiʻekiʻe. Hiki iā ia ke hoʻopau i ka nui o ka hana welding i kahi manawa pōkole a hoʻomaikaʻi i ka hana hana. He kūpono ke kuʻekuʻe wāwae i lalo no ka automation a me nā wahi kiʻekiʻe. Hiki iā ia ke hoʻopau i ka nui o ka hana welding i kahi manawa pōkole a hoʻomaikaʻi i ka hana hana. Hoʻohana maʻamau ʻia ka welding arc submerged e wili i nā ʻāpana metala ʻoi aku ka mānoanoa no ka mea ʻoi aku ka maikaʻi o kēia mau noi. Ma muli o ka uhiʻia o ka weld e ka flux, hiki ke pale maikaʻiʻia ka oxygen mai ke komoʻana i ka'āpana weld, a laila e ho'ēmi i ka hiki ke hoʻonāʻia a me ka spatter. I loko o ka hoʻoheheʻe ʻia ʻana, hiki ke hoʻohana ʻia nā uea wili a me nā arcs i ka manawa like e hoʻokō ai i ka wiliwili lehulehu (multi-layer) a hoʻomaikaʻi i ka pono.

He aha nā mea e hoʻohana ai i nā kuʻi hao H?

Hoʻohana nui ʻia nā kukuna H stainless steel i ke kūkulu ʻana, ka ʻenekinia moana, nā mea hana ʻoihana, nā kaʻa, nā papahana ikehu, a me nā ʻano ʻē aʻe ma muli o ko lākou kūpaʻa ʻana a me ka lōʻihi. Hāʻawi lākou i ke kākoʻo hoʻolālā i nā papahana kūkulu a hoʻokani i kahi hana koʻikoʻi i nā kaiapuni e koi ana i ka pale ʻana i ka corrosion, e like me ke kai a i ʻole ka ʻoihana. Hoʻohui ʻia, ʻo kā lākou hiʻohiʻona hou a me ka aesthetic e kūpono iā lākou no nā noi hoʻolālā hale a me loko.

Pehea ka pololei o ke kuʻihao HI?

ʻO ka pololei o ke kila kila H-beam, e like me nā mea hana, he mea nui ia i kāna hana a hoʻokomo. Ma keʻano laulā, hana nā mea hana i nā mea kila kila H-beam me kahi kiʻekiʻe o ka pololei e hoʻokō i nā kūlana ʻoihana a me nā kikoʻī.

ʻO ka maʻamau o ka ʻoihana i ʻae ʻia no ka pololei i ke kila hoʻolālā, me ke kila kila H-beams, ua wehewehe pinepine ʻia ma ke ʻano o nā ʻae ʻae ʻia mai kahi laina pololei ma luna o kahi lōʻihi i kuhikuhi ʻia. Hōʻike maʻamau ʻia kēia haʻalele ʻana ma ke ʻano o ka millimeters a i ʻole iniha o ka sweep a i ʻole ka hoʻoneʻe ʻaoʻao.

Hoʻolauna i ke ʻano o ka kukuna H ?

ʻO ke ʻano keʻa o ke kila I-beam, i ʻike mau ʻia ʻo "工字钢" (gōngzìgāng) ma ka ʻōlelo Kina, ua like ia me ka huapalapala "H" i ka wā i wehe ʻia ai. ʻO ka mea maʻamau, ʻo ka ʻāpana keʻa he ʻelua mau kaola ākea (flanges) ma luna a me lalo a me kahi pahu waena kū pololei (pūnaewele). Hāʻawi kēia ʻano "H" i ka ikaika a me ke kūpaʻa i ke kila I-beam, e lilo ia i mea hana maʻamau i ke kūkulu ʻana a me ka ʻenekinia. ʻO kēia hoʻonohonoho hoʻonohonoho e hiki ai i ke kila I-beam ke puʻunaue pono i nā ukana ke kau ʻia i nā ikaika, e hāʻawi ana i ke kākoʻo paʻa. Ma muli o kona ʻano kū hoʻokahi a me nā hiʻohiʻona hoʻolālā, ʻike nui ka I-beam steel i ka hoʻohana nui ʻana i ka hana o ke kūkulu ʻana a me ka ʻenekinia.

Pehea e hōʻike ai i ka nui a me ka hōʻike ʻana o I-beam?

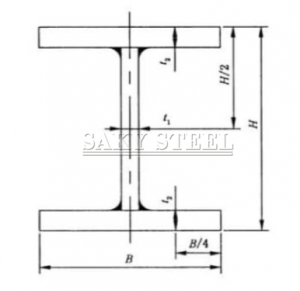

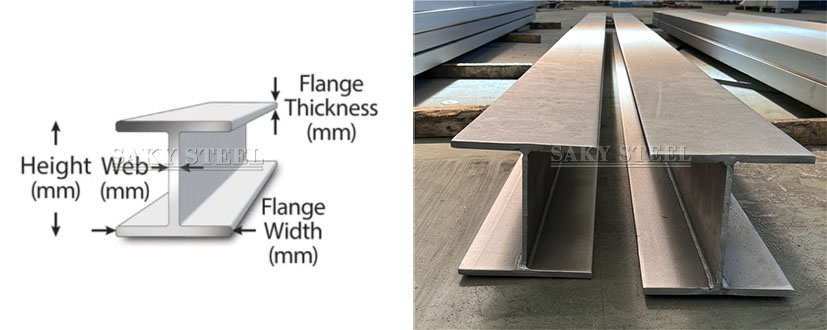

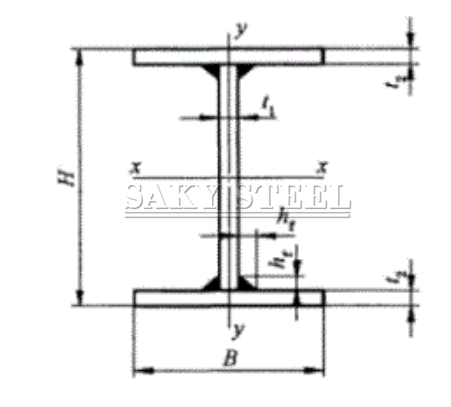

Ⅰ. Kiʻi ʻaoʻao ʻāpana a me nā hōʻailona hōʻailona o 316L kila kuhili ʻole i wili ʻia me ke kila H-like:

H——Ke kiekie

B——Ka laula

t1——Ka mānoanoa pūnaewele

t2——Ka mānoanoa pā flange

h£——Ka nui o ka welding (i ka hoʻohana ʻana i ka hui pū ʻana o nā welds a me nā fillet, ʻo ia ka nui o ka wāwae wili i hoʻoikaika ʻia hk)

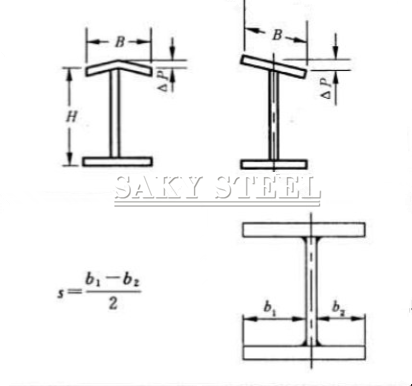

Ⅱ. Nā ana, nā ʻano a me nā ʻae ʻae ʻia o 2205 duplex steel welded H-like kila:

| H Kaola | Hoʻomanawanui |

| Aloha (H) | ʻOi aku ma mua o 300:3.0mm |

| Laulā (B) | 2.0mm |

| Perpendicularlty (T) | 1.2% a i ʻole ka liʻiliʻi o ka wldth (B) E hoʻomanaʻo he 2.0 mm ka hoʻomanawanui liʻiliʻi. |

| Offset o ke kikowaena (C) | 2.0mm |

| Kulou ana | 0.2096 a i ʻole ka lōʻihi |

| Ka lōʻihi o ka wāwae (S) | [hōʻoluʻolu o ka pā pūnaewele (t1) x0.7] a i ʻole |

| Ka lōʻihi | 3~12m |

| Hoʻomanawanui lōʻihi | +40mm,一0mm |

Ⅲ. ʻO nā ana, nā ʻano a me nā ʻae ʻae ʻia o ke kila H-like welded

Ⅳ. ʻO nā ʻāpana keʻa, ʻāpana keʻa, ke kaumaha kumu a me nā ʻāpana hiʻohiʻona keʻa o ke kila H-like welded.

| Na Kaola kila kila | Nui | ʻĀpana Māhele(cm²) | Kaumaha (kg/m) | Nā Kūlana Kūlana | ʻO ka nui o ka waihona huila h(mm) | ||||||||

| H | B | t1 | t2 | xx | yy | ||||||||

| mm | I | W | i | I | W | i | |||||||

| WH100X50 | 100 | 50 | 3.2 | 4.5 | 7.41 | 5.2 | 123 | 25 | 4.07 | 9 | 4 | 1.13 | 3 |

| 100 | 50 | 4 | 5 | 8.60 | 6.75 | 137 | 27 | 3.99 | 10 | 4 | 1.10 | 4 | |

| WH100X100 | 100 | 100 | 4 | 6 | 15.52 | 12.18 | 288 | 58 | 4.31 | 100 | 20 | 2.54 | 4 |

| 100 | 100 | 6 | 8 | 21.04 | 16.52 | 369 | 74 | 4.19 | 133 | 27 | 2.52 | 5 | |

| WH100X75 | 100 | 75 | 4 | 6 | 12.52 | 9.83 | 222 | 44 | 4.21 | 42 | 11 | 1.84 | 4 |

| WH125X75 | 125 | 75 | 4 | 6 | 13.52 | 10.61 | 367 | 59 | 5.21 | 42 | 11 | 1.77 | 4 |

| WH125X125 | 125 | 75 | 4 | 6 | 19.52 | 15.32 | 580 | 93 | 5.45 | 195 | 31 | 3.16 | 4 |

| WH150X75 | 150 | 125 | 3.2 | 4.5 | 11.26 | 8.84 | 432 | 58 | 6.19 | 32 | 8 | 1.68 | 3 |

| 150 | 75 | 4 | 6 | 14.52 | 11.4 | 554 | 74 | 6.18 | 42 | 11 | 1.71 | 4 | |

| 150 | 75 | 5 | 8 | 18.70 | 14.68 | 706 | 94 | 6.14 | 56 | 15 | 1.74 | 5 | |

| WH150X100 | 150 | 100 | 3.2 | 4.5 | 13.51 | 10.61 | 551 | 73 | 6.39 | 75 | 15 | 2.36 | 3 |

| 150 | 100 | 4 | 6 | 17.52 | 13.75 | 710 | 95 | 6.37 | 100 | 20 | 2.39 | 4 | |

| 150 | 100 | 5 | 8 | 22.70 | 17,82 | 908 | 121 | 6.32 | 133 | 27 | 2.42 | 5 | |

| WH150X150 | 150 | 150 | 4 | 6 | 23.52 | 18.46 | 1 021 | 136 | 6,59 | 338 | 45 | 3.79 | 4 |

| 150 | 150 | 5 | 8 | 30.70 | 24.10 | 1 311 | 175 | 6.54 | 450 | 60 | 3.83 | 5 | |

| 150 | 150 | 6 | 8 | 32.04 | 25,15 | 1 331 | 178 | 6.45 | 450 | 60 | 3.75 | 5 | |

| WH200X100 | 200 | 100 | 3.2 | 4.5 | 15.11 | 11.86 | 1 046 | 105 | 8.32 | 75 | 15 | 2.23 | 3 |

| 200 | 100 | 4 | 6 | 19.52 | 15.32 | 1 351 | 135 | 8.32 | 100 | 20 | 2.26 | 4 | |

| 200 | 100 | 5 | 8 | 25.20 | 19.78 | 1 735 | 173 | 8.30 | 134 | 27 | 2.30 | 5 | |

| WH200X150 | 200 | 150 | 4 | 6 | 25.52 | 20.03 | 1 916 | 192 | 8.66 | 338 | 45 | 3.64 | 4 |

| 200 | 150 | 5 | 8 | 33.20 | 26.06 | 2 473 | 247 | 8.63 | 450 | 60 | 3.68 | 5 | |

| WH200X200 | 200 | 200 | 5 | 8 | 41.20 | 32.34 | 3 210 | 321 | 8.83 | 1067 | 107 | 5.09 | 5 |

| 200 | 200 | 6 | 10 | 50.80 | 39.88 | 3 905 | 390 | 8.77 | 1 334 | 133 | 5,12 | 5 | |

| WH250X125 | 250 | 125 | 4 | 6 | 24.52 | 19.25 | 2 682 | 215 | 10.46 | 195 | 31 | 2.82 | 4 |

| 250 | 125 | 5 | 8 | 31.70 | 24.88 | 3 463 | 277 | 10.45 | 261 | 42 | 2.87 | 5 | |

| 250 | 125 | 6 | 10 | 38.80 | 30.46 | 4210 | 337 | 10.42 | 326 | 52 | 2.90 | 5 | |

ʻO kā mākou mau mea kūʻai

Manaʻo manaʻo mai kā mākou mea kūʻai mai

ʻO nā kuʻekuʻe hao hao he mau mea hoʻolālā i hana ʻia mai ke kila kila kila maikaʻi loa. Hōʻike kēia mau kahawai i kahi ʻano "H" ʻokoʻa, e hāʻawi ana i ka ikaika a me ke kūpaʻa i nā ʻano hana like ʻole a me nā palapala hoʻolālā. nā ʻoihana, me ke kūkulu ʻana, ka hale hana, a me ka hana ʻana, kahi e pono ai ke kākoʻo paʻa.

Hoʻopili ʻia ke kila kila ʻole:

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka hopohopo kūikawā e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana ma nā ʻano he nui, e like me,