1 Inch Steel Tubing for Ideal Projects: Quality Options & Expert Tips

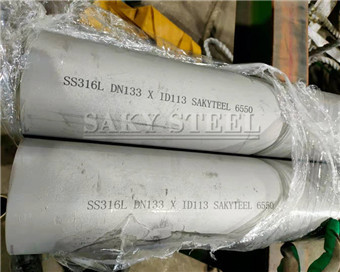

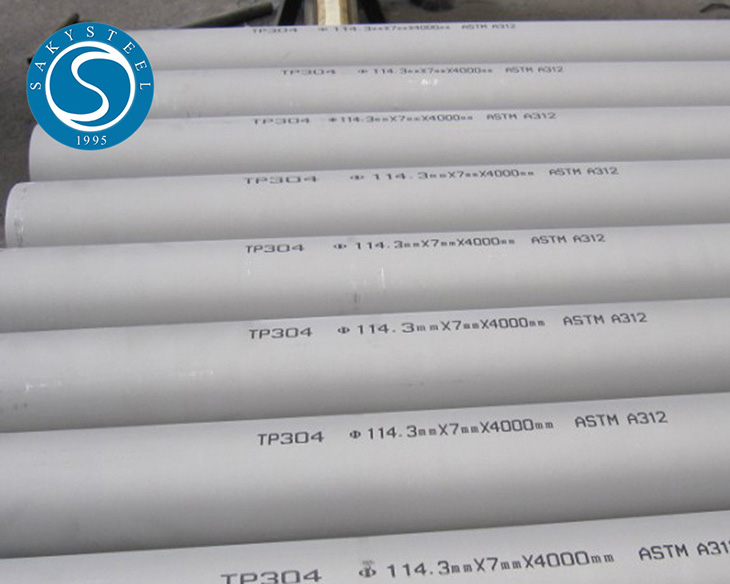

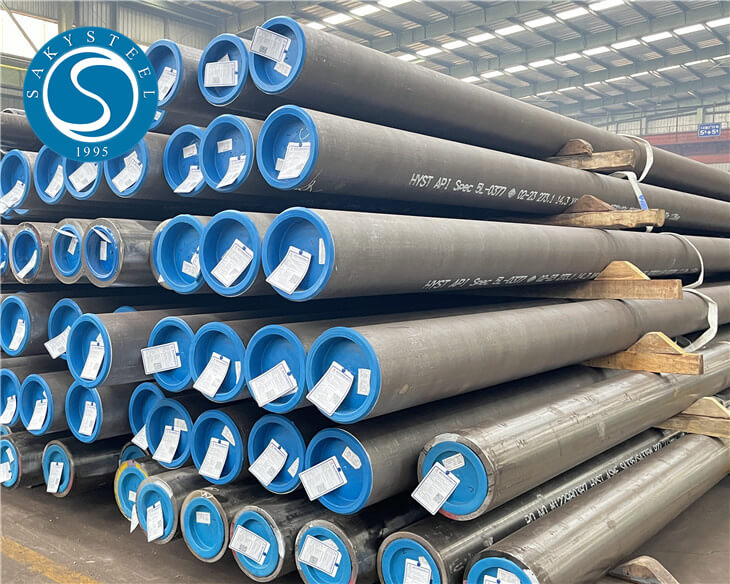

When it comes to sourcing high-quality 1 Inch Steel Tubing, I understand the importance of durability and reliability in your projects. This steel tubing is perfect for a wide range of applications, from structural components to automotive fabrication. I’ve seen how essential it is for businesses to have access to materials that meet stringent quality standards, ensuring safety and longevity. With our 1 Inch Steel Tubing, you can expect exceptional strength while maintaining a lightweight profile, which makes it easy to work with. I know that timely delivery and competitive pricing are crucial for B2B partnerships, and we pride ourselves on meeting those needs. The seamless finish allows for hassle-free installation, so you can focus on what you do best. Trust me, you won’t be disappointed with the performance of our steel tubing, as it is tailored to meet the demands of your industry. Let's build something great together!

1 Inch Steel Tubing For the Current Year Where Innovation Meets 2025

In 2025, the landscape of steel tubing is undergoing a transformative shift marked by innovation and a heightened focus on sustainability. One-inch steel tubing, known for its versatility and durability, is increasingly becoming the material of choice across various sectors, including construction, automotive, and manufacturing. Global procurement professionals are now prioritizing suppliers that not only deliver high-quality products but also commit to environmentally friendly practices. This evolution is driven by advancements in technology and a growing awareness of the importance of sustainable sourcing. As the demand for one-inch steel tubing rises, so does the need for innovative solutions. Manufacturers are investing in cutting-edge methods that enhance the longevity and performance of steel products while minimizing the carbon footprint. This includes employing new alloy compositions and advanced fabrication techniques that optimize strength and reduce weight, making them more efficient for transportation and installation. Such advancements not only improve product performance but also align with global sustainability goals, making them appealing to eco-conscious buyers. Navigating the procurement landscape in 2025 requires a strategic approach. Forward-thinking businesses are seeking partnerships with suppliers that can provide not only the best products but also insights into the latest industry trends and sustainability practices. By prioritizing innovation and eco-friendliness in their procurement decisions, companies can ensure they remain competitive while contributing positively to the environment. The one-inch steel tubing market is positioned at the forefront of this exciting evolution, heralding a future where quality and sustainability go hand in hand.

1 Inch Steel Tubing For the Current Year Where Innovation Meets 2025

| Dimension | Material Type | Weight (lbs/ft) | Strength (psi) | Application |

|---|---|---|---|---|

| 1.0 x 0.120 | Mild Steel | 0.40 | 40,000 | Structural Support |

| 1.0 x 0.250 | Stainless Steel | 0.65 | 70,000 | Pipe Fitting |

| 1.0 x 0.156 | Aluminum | 0.38 | 35,000 | Lightweight Structures |

| 1.0 x 0.375 | Carbon Steel | 0.80 | 60,000 | Heavy Duty Frames |

| 1.0 x 0.500 | High Strength Steel | 1.00 | 90,000 | Industrial Equipment |

Related Products