2.25 Steel Tubing: Durable Options for Your Construction Projects

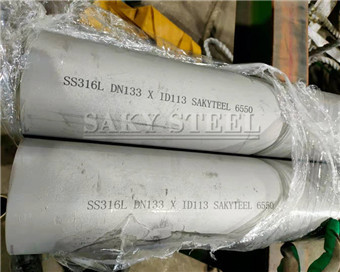

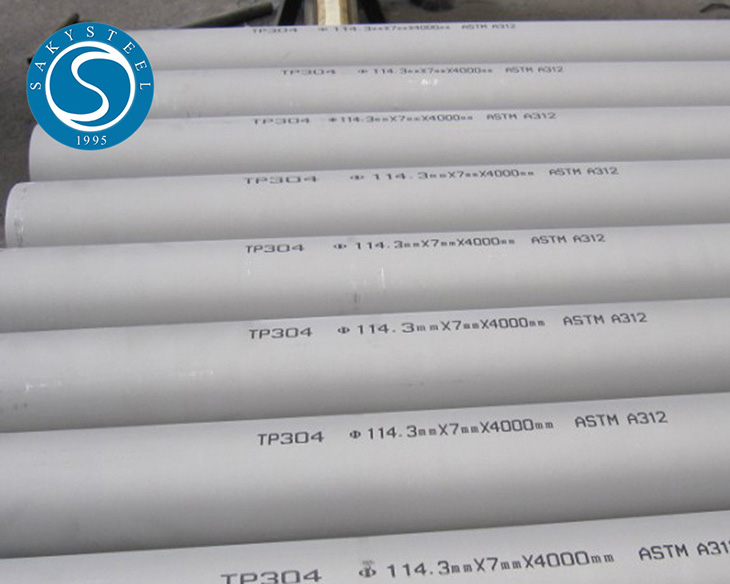

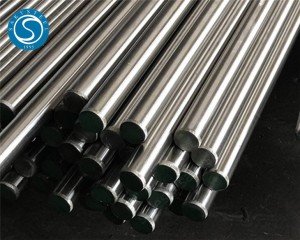

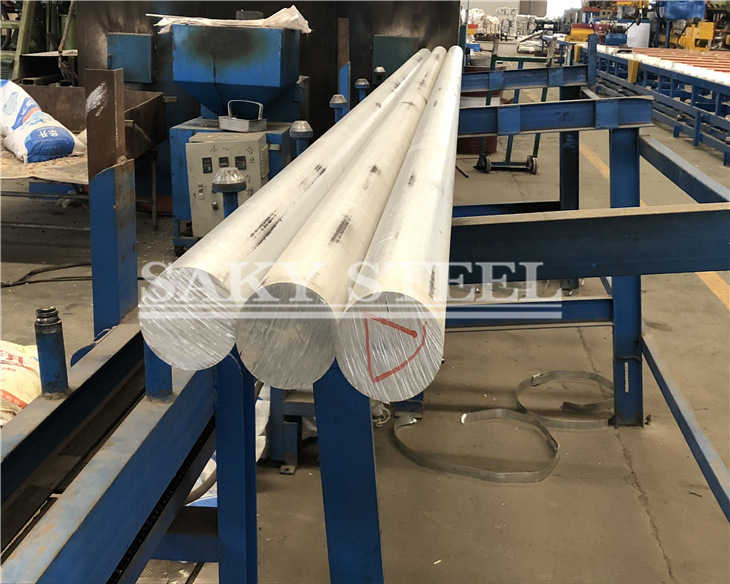

When I think about reliable materials for heavy-duty applications, 2.25 Steel Tubing is always top of mind. This tubing offers exceptional strength and durability, making it perfect for construction, automotive, and manufacturing needs. With its robust build, you can count on it to withstand even the toughest conditions, ensuring longevity in your projects. I understand that finding the right supplier is crucial. That’s why I’ve partnered with a company that emphasizes quality and consistency across all their steel products. Whether you’re seeking competitive pricing or timely delivery, this 2.25 Steel Tubing meets your needs and exceeds your expectations. I’ve seen many clients benefit from using this material in their designs, and it’s always a pleasure to witness their projects come to life with such dependable components. Let's elevate your projects together by choosing the right materials!

2.25 Steel Tubing Application Industry Leaders

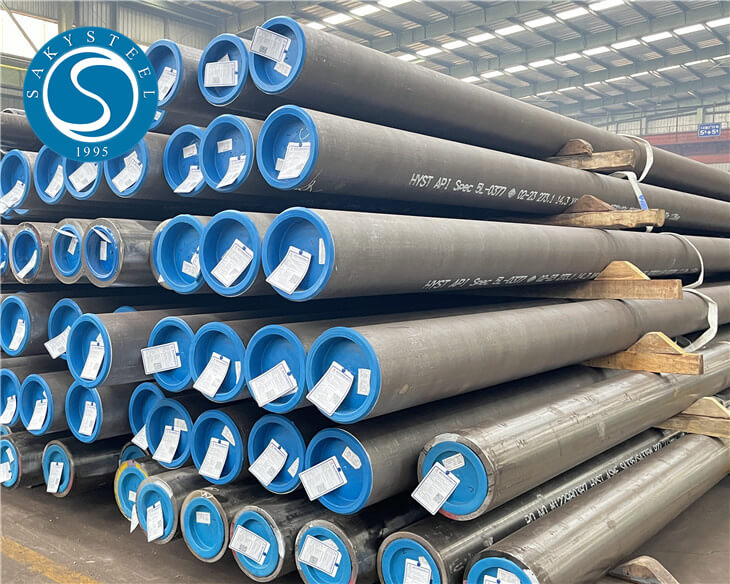

In the world of manufacturing and construction, the efficiency and reliability of materials play a pivotal role in project success. Among various choices, 2.25 steel tubing stands out for its excellent strength-to-weight ratio and versatility, making it an ideal selection across multiple industries. From structural applications in buildings to automotive and aerospace components, the adaptability of 2.25 steel tubing has attracted attention from industry leaders globally. One of the primary advantages of 2.25 steel tubing is its exceptional durability, which ensures long-lasting performance even in challenging environments. This makes it particularly suitable for industries that require high-quality, robust materials, such as energy, automotive, and construction. Furthermore, the ease of fabrication allows manufacturers to tailor the tubing to specific needs, thus enhancing operational efficiency and effectiveness. As demand rises, it is crucial for global procurement specialists to partner with suppliers who prioritize quality, innovation, and sustainability in their production processes. In addition to its physical properties, 2.25 steel tubing also plays a significant role in meeting stringent industry standards for safety and performance. As organizations strive for excellence and compliance, sourcing reliable materials becomes vital. Collaborating with established providers can ensure that businesses not only acquire top-notch products but also gain access to valuable insights into the latest industry trends and technologies. By leveraging these partnerships, companies can streamline their supply chains and remain at the forefront of their respective markets.

2.25 Steel Tubing Application Industry Leaders

| Application | Industry | Material Specifications | Common Uses | Regulatory Standards |

|---|---|---|---|---|

| Structural Support | Construction | ASTM A500 Grade B | Buildings, Bridges | ISO 9001 |

| Fluid Transfer | Oil & Gas | ASTM A53 Gr. B | Pipelines, Drilling Rigs | API Spec 5L |

| Automotive Components | Automotive | SAE J403 | Frames, Exhaust Systems | ISO/TS 16949 |

| Machinery Manufacturing | Industrial Equipment | ASTM A513 | Cylinders, Chassis | CE Marking |

| Construction and Framing | Construction | ASTM A486 | Scaffolding, Frames | OSHA Regulations |

Related Products