304 Stainless Tubing: Durable Options for Your Project Needs

When it comes to reliable and durable materials, I’ve found that 304 stainless tubing stands out. Perfect for various applications, from construction to food processing, this tubing offers excellent corrosion resistance and ease of fabrication. You might be in need of something that can handle tough environments without compromising on quality. I remember my own struggle to find the right supplier who understands both the technical details and the urgency of my projects. That's why I value partnerships with companies that prioritize customer satisfaction and timely delivery. Investing in 304 stainless tubing is a smart choice for any project that requires high performance and longevity. Join me in making the switch, and let’s ensure your next project gets the quality materials it deserves. If you have any specific needs or require custom lengths, just let me know, and I’ll help find the perfect solution for you.

304 Stainless Tubing Trusted by Pros Guarantees Peak Performance

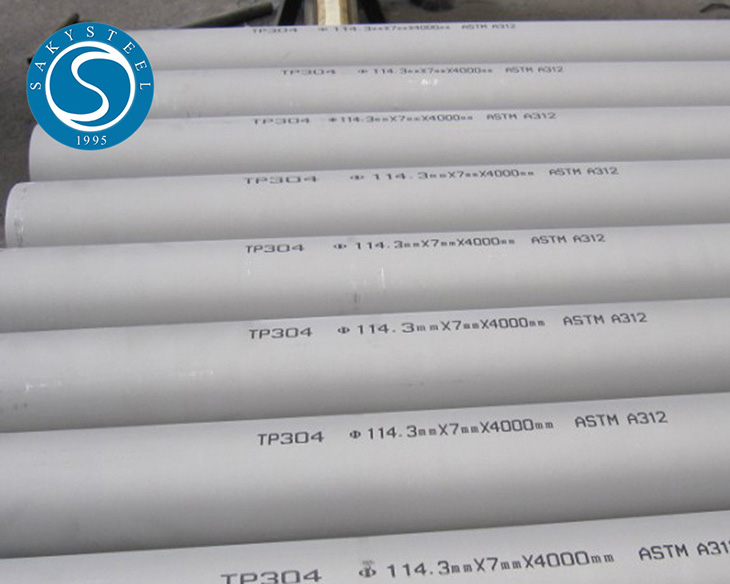

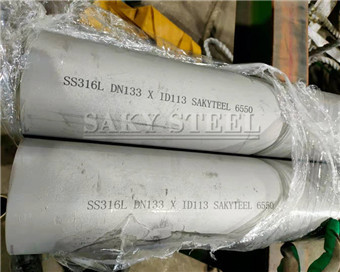

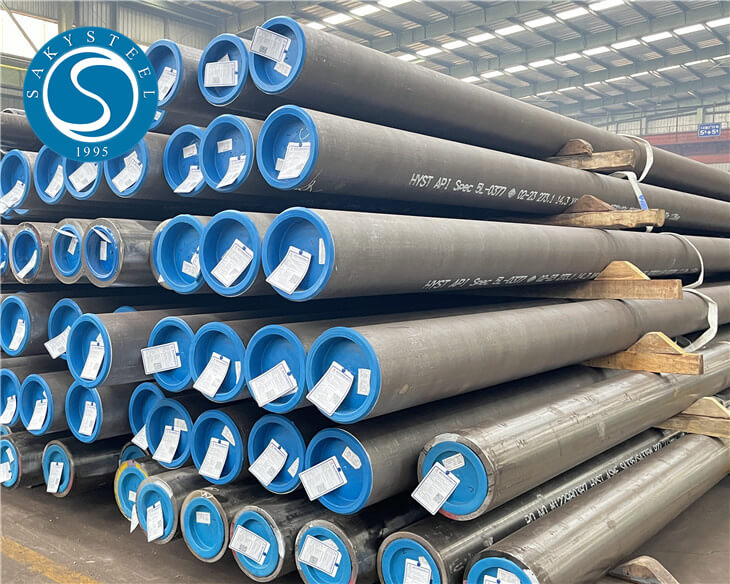

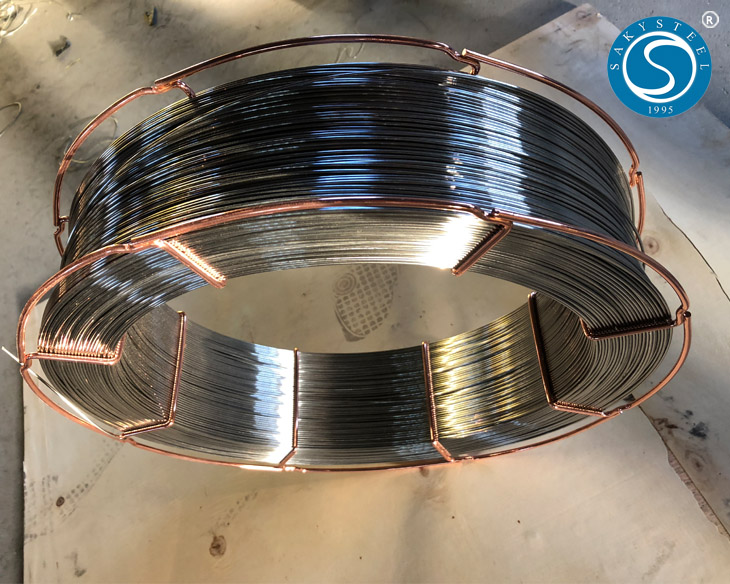

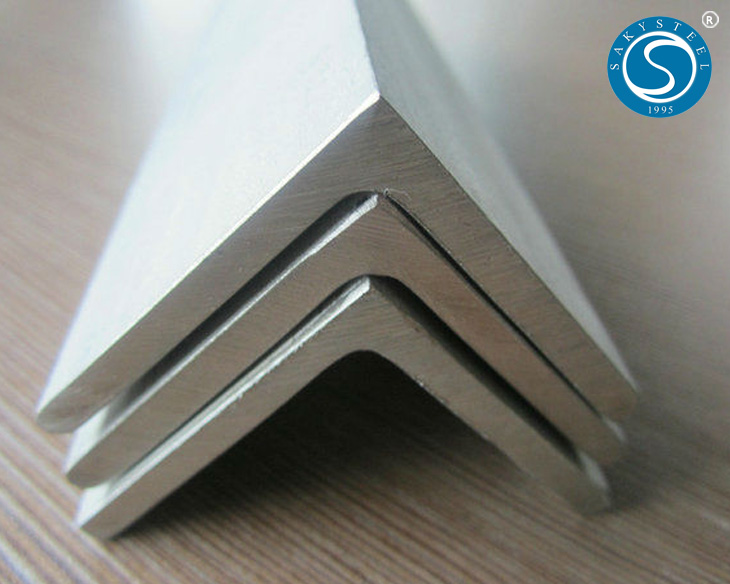

When it comes to selecting materials for industrial applications, the choice of tubing is critical for ensuring performance and durability. 304 stainless tubing is often the go-to solution for professionals seeking reliability and strength. Its excellent corrosion resistance and high strength make it ideal for a variety of applications, from food processing to chemical transportation. This grade of stainless steel is known for its versatility and can withstand high temperatures while maintaining structural integrity, ensuring that it meets the rigorous demands of industries around the globe. In addition to its superior mechanical properties, 304 stainless tubing offers ease of fabrication, making it a favorite among engineers and manufacturers alike. This means that it can be easily welded, fabricated, and formed into various shapes to fit specific requirements. For global buyers, sourcing high-quality 304 stainless tubing is essential to guarantee peak performance in their projects. By choosing a reputable supplier, procurement teams can ensure consistent quality and timely delivery, which are critical factors in maintaining production schedules and meeting client expectations. Ultimately, investing in 304 stainless tubing is about enhancing operational efficiency and ensuring long-lasting solutions. By partnering with trusted manufacturers who specialize in high-grade stainless steel products, businesses can secure the materials they need to optimize their operations and achieve success in their respective markets. Whether you’re looking to expand your existing supply chain or seeking new materials for innovative projects, 304 stainless tubing stands out as a reliable choice that professionals can count on.

304 Stainless Tubing Trusted by Pros Guarantees Peak Performance

| Attribute | Specification | Application | Key Benefits |

|---|---|---|---|

| Material | 304 Stainless Steel | Food Processing | Corrosion Resistance |

| Diameter | 1 inch | Fluid Transport | Strong Durability |

| Wall Thickness | 0.065 inch | Chemical Processing | Easy to Machine |

| Finish | Polished | Pharmaceuticals | Aesthetic Appeal |

| Temperature Range | -100°F to 1000°F | Heat Exchangers | Versatile Performance |

Related Products