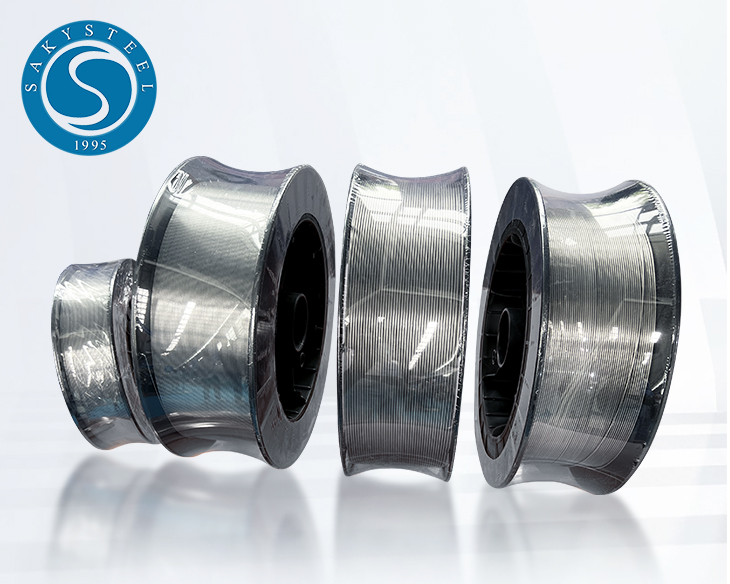

Top Quality 309 Welding Wire for Reliable Performance and Precision

When I first encountered 309 Welding Wire, I was impressed by its versatility and durability. This welding wire is perfect for joining dissimilar metals, making it a favorite for both industrial and manufacturing applications. I often highlight its excellent corrosion resistance and high-temperature strength, which really stood out during my projects. Buyers like you often seek wires that can handle tough environments without compromising quality, and 309 Welding Wire fits the bill perfectly. I appreciate how it’s easy to work with, providing consistent feedability and smooth arc stability, which saves time and reduces wastage. Whether you're engaged in automotive, aerospace, or heavy construction, this wire truly delivers results. I always recommend considering the specifications to ensure it meets your requirements. Choosing the right welding wire can make all the difference in the quality of your work!

309 Welding Wire Guarantees Peak Performance Where Innovation Meets 2025

In today's rapidly evolving manufacturing landscape, the demand for high-quality welding materials has reached unprecedented levels. The introduction of the 309 welding wire represents a remarkable advancement that merges innovation with unparalleled performance, ensuring that businesses can achieve their production goals efficiently and effectively. This specialized alloy wire, specifically designed for high-temperature applications, offers superior corrosion resistance and excellent weldability. Its unique composition makes it ideal for joining dissimilar metals, catering to a diverse range of industrial needs. As we approach 2025, the importance of reliable and innovative welding solutions cannot be overstated. Industries are increasingly focused on sustainability, efficiency, and quality, prompting a shift towards materials that not only meet regulatory standards but also enhance operational performance. The 309 welding wire is engineered to provide consistent results, minimizing rework and maximizing productivity. By investing in advanced welding technology, businesses can stay competitive in a global market that demands excellence. With a proven track record in meeting the rigorous demands of various sectors, from energy to construction, the 309 welding wire is poised to become a cornerstone for manufacturers aiming for excellence in their welding operations. Its exceptional characteristics offer global buyers the opportunity to enhance their processes, ensuring that their operations thrive in a challenging marketplace. As we move forward, embracing innovative solutions like the 309 welding wire will be essential for achieving peak performance and driving future growth.

| 309 Welding Wire Guarantees Peak Performance Where Innovation Meets 2025 | |||

|---|---|---|---|

| Wire Type | Diameter (mm) | Material Composition | Application |

| 309L | 1.0 | Fe, Cr, Ni | Stainless Steel Welding |

| 309Si | 1.2 | Fe, Cr, Ni, Si | High Temperature Applications |

| 309Ti | 1.6 | Fe, Cr, Ni, Ti | Corrosion Resistance |

| 309Mo | 0.8 | Fe, Cr, Ni, Mo | Marine Applications |

| 309Cb | 1.0 | Fe, Cr, Ni, Cb | Heat-Resistant Welding |

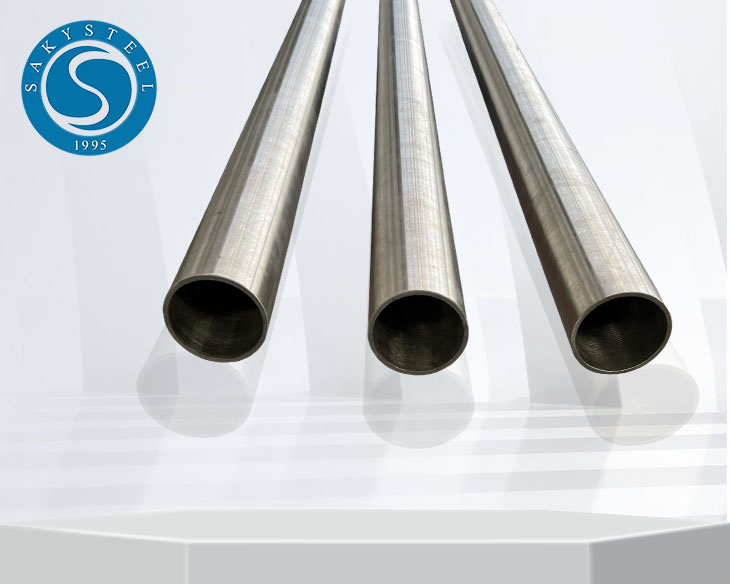

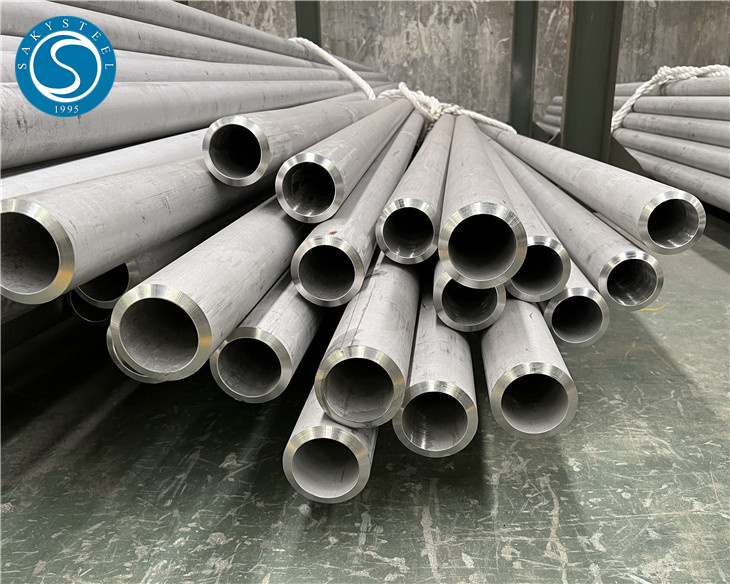

Related Products