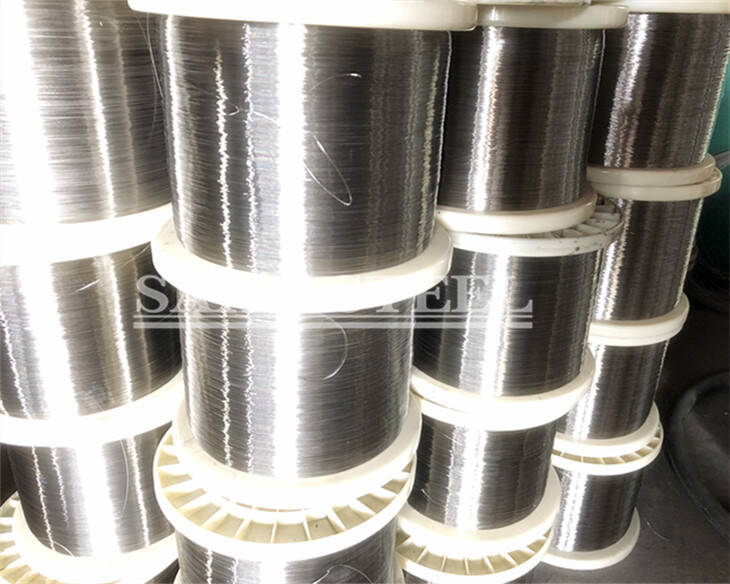

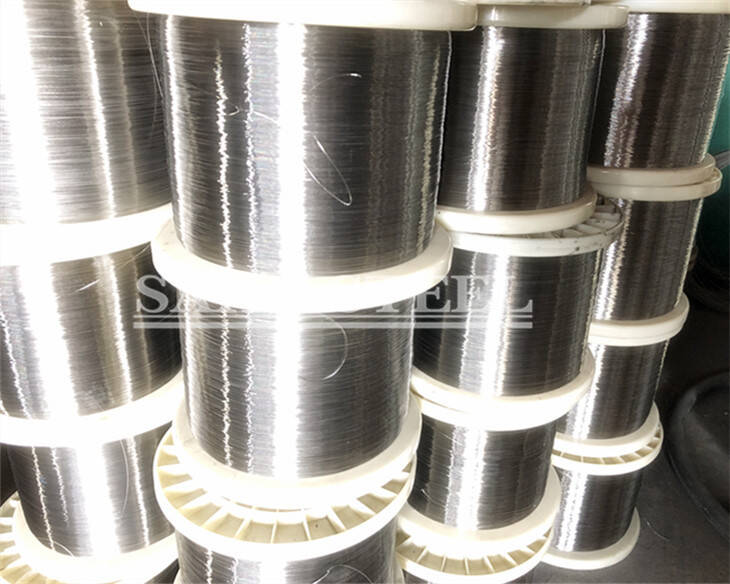

Find High-Quality 316 Stainless Steel Spring Wire for Your Projects

When I think about reliable materials for our manufacturing needs, 316 stainless steel spring wire always comes to mind. Its exceptional resistance to corrosion makes it perfect for various industries. I’ve found that this type of wire not only holds up in harsh environments but also maintains its strength under stress. Whether I'm sourcing for marine applications or medical devices, I can trust into its durability and performance. The flexibility of 316 stainless steel allows me to create intricate designs without compromising quality. Plus, knowing it's available in various diameters gives me peace of mind when planning production runs. If you're also seeking a dependable partner in your projects, I recommend checking out 316 stainless steel spring wire. It's an investment that's sure to pay off in the long run, ensuring the success of our shared endeavors.

316 Stainless Steel Spring Wire Products in 2025

As we look toward 2025, the demand for 316 stainless steel spring wire products is expected to rise significantly due to their unique properties and versatile applications. Known for their excellent resistance to corrosion and high strength, these products are ideal for industries ranging from automotive to aerospace, as well as the medical and electronics sectors. The combination of durability and reliability makes 316 stainless steel the go-to choice for manufacturers who prioritize quality and performance. In a global market that values sustainability and innovation, the adoption of advanced manufacturing processes plays a critical role in meeting the needs of discerning buyers. The continuous improvement in production techniques ensures that the quality of spring wire products not only meets but exceeds international standards. As procurement managers seek out suppliers who can provide consistent quality, the focus on raw material sourcing, engineering expertise, and sustainability practices is more crucial than ever. Looking ahead, businesses should consider the strategic advantages of sourcing high-quality 316 stainless steel spring wire products. Building partnerships with suppliers who understand market trends and offer customization options will be vital in staying competitive. As the industry evolves, those who embrace innovation and sustainability will lead the way, setting new benchmarks for quality and customer satisfaction.

316 Stainless Steel Spring Wire Products in 2025

| Product Type | Diameter (mm) | Tensile Strength (MPa) | Elongation (%) | Application Area |

|---|---|---|---|---|

| Compression Spring Wire | 0.50 | 860 | 10 | Automotive |

| Tension Spring Wire | 1.00 | 950 | 12 | Industrial Equipment |

| Extension Spring Wire | 1.50 | 900 | 9 | Construction |

| Oil Tempered Spring Wire | 2.00 | 1000 | 11 | Aerospace |

| Heat Resistant Spring Wire | 2.50 | 920 | 10 | Electronics |

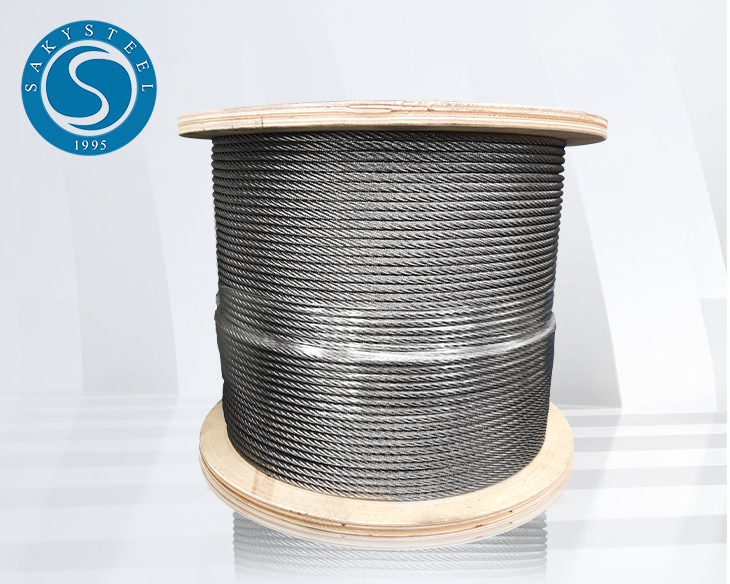

Related Products