Idan ana maganar kera ƙarfe, sharuɗɗa biyu sukan bayyana gefe da gefe: ƙirƙira da yi. Ko da yake suna iya kama da kama da kallon farko, suna wakiltar nau'ikan sarrafa ƙarfe guda biyu daban-daban tare da halaye na musamman, fa'idodin aiki, da aikace-aikace. Fahimtar bambanci tsakanin ƙirƙira da ƙarafa da aka yi yana da mahimmanci ga injiniyoyi, masana'anta, da masu siye lokacin zabar kayan da ya dace don takamaiman amfaninsu.

A cikin wannan labarin, za mu bincika bambance-bambancen da ke tsakanin ƙirƙira da ƙarafa da aka ƙera ta fuskar ma'anoni, hanyoyin masana'antu, kaddarorin inji, ƙa'idodi, misalan samfur, da ƙari.

1. Menene Ma'anar Ƙirƙirar Ƙarfe Ta Ƙarfe?

Ƙirƙira tsari ne na naƙasa wanda ya haɗa da yin amfani da ƙarfi mai ƙarfi zuwa ƙarfe, yawanci a yanayin zafi mai zafi, don siffanta shi zuwa sigar da ake so. Ana iya yin ƙirƙira ta hanyar guduma, latsa, ko mirgina ƙarfe ta amfani da mutu.

Mabuɗin Abubuwan Ƙarfe-Ƙarfe:

- Tsarin hatsi mai ladabi

- Babban ƙarfi da tauri

- Kyakkyawan juriya ga gajiya

- Ƙananan ɓoyayyiyar ciki ko haɗawa

Kayayyakin Ƙirƙirar Jama'a:

- Flanges

- Shafts

- Zobba

- Gears

- Matsalolin jirgin ruwa abubuwan

Nau'in Ƙarfafawa:

- Buɗe-mutu ƙirƙira: Ya dace don manyan abubuwan haɗin gwiwa.

- Rufe-mutu (mutuwar ra'ayi) ƙirƙira: Ana amfani da shi don ƙarin ingantattun siffofi.

- Ƙirƙirar zobe mara sumul: Yawancin lokaci ana amfani da shi a sararin samaniya da samar da wutar lantarki.

2. Menene Ƙarfe da Aka Yi?

Kalmar “aikin da aka yi” tana nufin ƙarfe da aka yi aiki da injina zuwa sigarsa ta ƙarshe, yawanci ta hanyar birgima, zane, fiɗa, ko ƙirƙira. Babban ra'ayin shi ne cewa ba a jefar da ƙarfe da aka yi ba, ma'ana ba a zubo su daga narkakkar ƙarfe zuwa gyare-gyare ba.

Halayen Ƙarfe da Aka Yi:

- Ductile da malleable

- Tsarin hatsi iri ɗaya

- Mafi sauki ga inji da walda

- Kyakkyawan gamawa

Samfuran gama-gari:

- Bututu da tubing

- Gishiri da tees

- Farantin karfe da takarda

- Waya da sanduna

- Siffofin tsari (I-beams, kusurwa)

3. Mabuɗin Bambanci Tsakanin Ƙarfe-Ƙarfe da Ƙarfe-Ƙara

| Siffar | Karfe Karfe | Aikin Karfe |

|---|---|---|

| Ma'anarsa | Matsa a ƙarƙashin babban matsin lamba | An yi aiki da injina amma ba a jefa ba |

| Tsarin hatsi | Daidaita kuma mai ladabi | Uniform amma kasa mai yawa |

| Ƙarfi | Ƙarfin ƙarfi da ƙarfi | Ƙarfin matsakaici |

| Aikace-aikace | Babban matsi, sassa masu yawan damuwa | Aikace-aikacen tsarin gabaɗaya |

| Tsari | Karɓar latsa, guduma, mutu | Mirgina, zane, extruding |

| Farashin | Mafi girma saboda kayan aiki da makamashi | Ƙarin tattalin arziki a cikin adadi mai yawa |

| Ƙarshen Sama | Mafi ƙanƙanta (ana iya yin inji) | Gabaɗaya mafi santsi |

4. Matsayi da Takaddun shaida

Kayayyakin jabu:

- ASTM A182 (Forged ko Rolled Alloy da Bakin Karfe Bututu Flanges)

- ASTM B564 (Nickel Alloy Forgings)

- ASME B16.5 / B16.47

Kayayyakin Aiki:

- ASTM A403 (Austenitic Bakin Karfe Bututu Fittings)

- ASTM A240 (Bakin Karfe Plate, Sheet, da Strip)

- Bakin Karfe Mechanical Tubing (ASTM A554)

5. Wanne Ya Kamata Ku Zaba: Ƙirƙirar Ko Aka Yi?

Zaɓin tsakanin ƙirƙira da ƙarfe na ƙarfe ya dogara sosai akan buƙatun aikace-aikacen:

Zaɓi ƙarfe na jabu lokacin:

- Bangaren yana ƙarƙashin babban damuwa ko matsa lamba (misali, flanges masu matsa lamba, madaidaicin ramummuka)

- Ana buƙatar babban ƙarfi da juriya ga gajiya

- Mutuncin girman yana da mahimmanci a ƙarƙashin kaya

Zaɓi karfen da aka ƙera lokacin da:

- Bangaren baya fuskantar matsanancin lodi

- Machinability da weldability suna da mahimmanci

- Ana buƙatar samar da girma mai girma a ƙananan farashi

6. Aikace-aikacen masana'antu

| Masana'antu | Kayayyakin jabu | Kayan Aiki |

| Mai & Gas | Babban matsa lamba bawuloli, flanges | Kayan aikin bututu, gwiwar hannu |

| Jirgin sama | Sassan injin jet, injin turbin | Dabarun tsarin, maƙallan |

| Motoci | Crankshafts, sanduna masu haɗawa | Fannin jiki, bututun shaye-shaye |

| Samar da Wutar Lantarki | Turbine rotors, zobba | Condenser tubes, takardar karfe |

| Gina | Kayan aiki masu ɗaukar nauyi | Biams, bayanan martaba |

7. Halayen Ƙarfe: Me yasa Ƙirƙirar Ƙarfe ke Ƙarfafa Ƙarfe

Ƙirƙirar ƙirƙira tana daidaita kwararar hatsi don bin siffar ɓangaren, kawar da katsewa da iyakokin hatsi waɗanda ke aiki azaman maki masu rauni. Wannan gyare-gyaren hatsi yana sa abubuwan da aka ƙirƙira su yi ƙarfi sosai kuma sun fi dogaro a cikin mahalli masu tsananin gajiya.

Abubuwan da aka ƙera suma suna amfana daga aikin injina, amma tsarin cikin gida bai inganta ba fiye da ɓangarorin ƙirƙira.

8. Tambayoyi Game da Ƙarfe da Aka Yi

Za a iya ƙirƙira da yin ƙarfe duka?

Ee. "An yi" yana bayyana yanayin gaba ɗaya na aikin filastik, kuma ƙirƙira nau'in tsari ɗaya ne.

Karfe na simintin iri ɗaya ne da aka yi?

A'a. Ƙarfe na simintin gyare-gyare ana yin shi ta hanyar zuba narkakkar ƙarfe a cikin wani gyaggyarawa, kuma yana son ya sami manyan sifofin hatsi da ƙarin porosity.

Wanne ya fi dacewa da juriya na lalata?

Juriya na lalata ya dogara da abun da ke ciki. Koyaya, kayan jabu na iya bayar da mafi kyawun juriya a wasu mahalli saboda raguwar porosity.

Shin karfen da aka yi ya fi qarfin jabu?

Gabaɗaya a'a. Ƙarfe da aka ƙirƙira ya fi ƙarfi saboda ingantacciyar daidaituwar hatsi da ƙarancin lahani na ciki.

9. Kwatanta Kayayyakin Kayayyakin: Ƙirƙirar Kayayyakin Karfe da Aka Yi

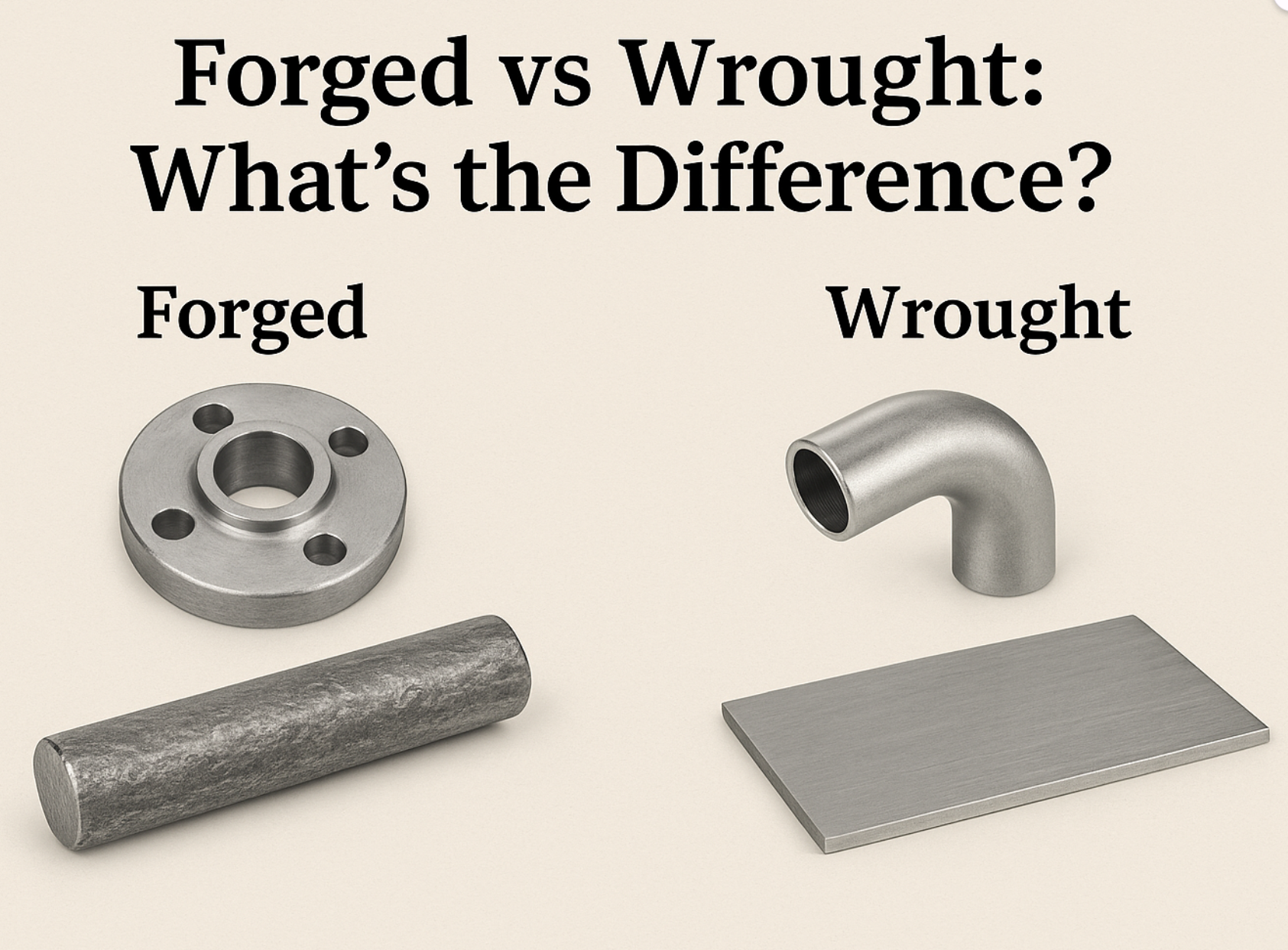

(Haɗa hoton kwatancen da ke nuna ƙirƙira flange da sanda vs ƙwanƙwasa gwiwar hannu da takarda)

10. Kammalawa: Sani Karfe ku, Zabi da Amincewa

Fahimtar bambance-bambancen da ke tsakanin ƙirƙira da ƙarafa da aka yi yana da mahimmanci a aikin injiniya da aikace-aikacen masana'antu. Abubuwan da aka ƙirƙira suna ba da ƙarfi mafi ƙarfi, juriya na gajiya, da tsarin hatsi, yana mai da su manufa don sassa masu tsananin damuwa. Abubuwan da aka ƙera, a gefe guda, suna ba da ingantaccen farashi, daidaito, da ingantaccen tsari don amfanin gaba ɗaya.

Lokacin zabar samfuran ƙarfe don aikinku, koyaushe la'akari:

- Yanayin aikace-aikace

- Abubuwan da ake buƙata na inji

- Matsayin masana'antu

- Kasafin kudin masana'antu

Ko kuna samo bakin karfe ko kayan aikin gwiwar hannu, sanin asalin masana'anta - ƙirƙira ko aiki - yana taimakawa tabbatar da zaɓin ƙarfe daidai, tare da aikin da ya dace, akan farashi mai dacewa.

Lokacin aikawa: Yuli-22-2025