Kana zvasvika pakugadzira simbi, mazwi maviri anowanzo kuoneka padivi nepadivi: akagadzirwa uye akaitwa. Kunyangwe iwo angangoita seakafanana pakutanga kuaona, anomiririra mapoka maviri akasiyana ekugadzirwa kwesimbi ane akasiyana maitiro, mabhenefiti ekuita, uye mashandisirwo. Kunzwisisa mutsauko uripo pakati pesimbi dzakagadzirwa uye dzakagadzirwa kwakakosha kune mainjiniya, vagadziri, uye vatengi kana vachisarudza chinhu chakakodzera chekushandisa kwavo chaiko.

Muchinyorwa chino, tichaongorora mutsauko uripo pakati pesimbi dzakagadzirwa uye dzakagadzirwa maererano netsananguro, maitiro ekugadzira, michina zvivakwa, zviyero, mienzaniso yechigadzirwa, nezvimwe.

1. Forged Zvinorevei Mukugadzira Simbi?

Forging ideformation process inosanganisira kushandisa compressive forces kusimbi, kazhinji pakupisa kwepamusoro, kuiumba kuita fomu yaunoda. Kugadzira kunogona kuitwa nekurova, kudzvanya, kana kukungurutsa simbi uchishandisa dies.

Zvinokosha zveForged Metal:

- Yakanatswa zviyo chimiro

- High simba uye kuoma

- Zvirinani kuneta kuramba

- Vashoma vemukati voids kana inclusions

Common Forged Products:

- Flanges

- Shafts

- Rings

- Magiya

- Pressure mudziyo zvikamu

Mhando dzeForging:

- Open-die forging: Yakanakira zvikamu zvakakura.

- Yakavharwa-fa (impression die) forging: Inoshandiswa kune mamwe chaiwo maumbirwo.

- Seamless yakatenderedzwa mhete yekugadzira: Inowanzo shandiswa mumhepo uye kugadzira magetsi.

2. Chii Chinonzi Wrought Metal?

Izwi rekuti "yakagadzirwa" rinoreva simbi yakashandiswa nemuchina kuita fomu yekupedzisira, kazhinji nekukunguruka, kudhirowa, kuburitsa, kana kuforoma. Pfungwa huru ndeyokuti simbi dzakagadzirwa hadzina kukandwa, kureva kuti hadzina kudirwa kubva musimbi yakanyungudutswa kuita mould.

Hunhu hweWrought Metal:

- Ductile uye inogadzirwa

- Uniform zviyo chimiro

- Zviri nyore kuita muchina uye weld

- Kupera kwakanaka kwepamusoro

Common Wrought Products:

- Pombi uye tubing

- Maelbows uye tees

- Ndiro uye sheet simbi

- Waya netsvimbo

- Zvimiro zvechimiro (I-matanda, makona)

3. Misiyano Yakakosha Pakati Pesimbi Yakagadzirwa uye Yakagadzirwa

| Feature | Forged Metal | Wrought Metal |

|---|---|---|

| Tsanangudzo | Kumanikidzwa pasi pekumanikidzwa kwakanyanya | Mechanic akashanda asi kwete kukandwa |

| Chimiro chezviyo | Yakarongeka uye yakanatswa | Uniform asi zvishoma dense |

| Simba | Kusimba kwepamusoro uye kuoma | Simba riri pakati nepakati |

| Applications | High-pressure, high-stress parts | General structural applications |

| Process | Forging press, sando, kufa | Kukunguruka, kudhirowa, kuburitsa |

| Mutengo | Yakakwirira nekuda kwekushandisa uye simba | Zvimwe zvehupfumi muhuwandu hukuru |

| Surface Finish | Yakaoma nzvimbo (inogona kugadzirwa) | Kazhinji yakatsetseka pamusoro |

4. Mitemo uye Zvitupa

Forged Products:

- ASTM A182 (Forged kana Rolled Alloy uye Stainless Steel Pipe Flanges)

- ASTM B564 (Nickel Alloy Forgings)

- ASME B16.5 / B16.47 (Forged Flanges)

Zvakagadzirwa:

- ASTM A403 (Yakagadzirwa Austenitic Stainless Simbi Pipe Fittings)

- ASTM A240 (Yakagadzirwa Stainless Simbi Plate, Sheet, uye Strip)

- ASTM A554 (Welded Stainless Steel Mechanical Tubing)

5. Ndeipi Yaunofanira Kusarudza: Yakagadzirwa Kana Kuti Yakagadzirwa?

Sarudzo pakati pesimbi yakagadzirwa neyakagadzirwa zvinoenderana zvakanyanya nezvinodiwa zvekushandisa:

Sarudza simbi yakagadzirwa kana:

- Chikamu chiri pasi pekunetseka kwakanyanya kana kudzvanywa (semuenzaniso, high-pressure flanges, yakakosha shafts)

- Kusimba kwepamusoro uye kuramba kuneta kunodiwa

- Dimensional kutendeseka kwakakosha pasi pemutoro

Sarudza simbi yakagadzirwa kana:

- Icho chikamu hachione kunyanyisa kurodha

- Machinability uye weldability zvakakosha

- Kugadzirwa kwepamusoro-soro kunodiwa nemutengo wakaderera

6. Indasitiri Applications

| Indasitiri | Forged Products | Wrought Products |

| Mafuta & Gasi | High-pressure valves, flanges | Pipe fittings, magokora |

| Aerospace | Jet injini zvikamu, turbine disks | Zvivako mapaneru, mabhureki |

| Automotive | Crankshafts, tsvimbo dzinobatanidza | Body panels, exhaust tubing |

| Power Generation | Turbine rotors, zvindori | Condenser machubhu, sheet simbi |

| Kuvaka | Majoini anotakura mutoro | Mitsipa, zvimiro profiles |

7. Metallurgical Insights: Sei Forging Inoita Yakasimba Metal

Kugadzira kunogadzirisa kuyerera kwezviyo kutevera chimiro chechikamu, kubvisa discontinuities uye miganhu yezviyo inoita senge isina simba. Uku kunatswa kwezviyo kunoita kuti zvikamu zvakaumbwa zvisimbe zvakanyanya uye zvakavimbika munzvimbo dzinonzwa kuneta.

Zvishandiso zvakakanyiwa zvinobatsirawo kubva mukushanda kwemakanika, asi chimiro chemukati hachina kugadziridzwa kupfuura muzvikamu zvakaumbwa.

8. FAQs About Forged and Wrought Metal

Ko simbi ingagadzirwa nekugadzirwa here?

Ehe. "Wrought" inotsanangura mamiriro ezvinhu ekushandiswa kwepurasitiki, uye kuumba imhando imwe yemaitiro akaitwa.

Simbi yakakandwa yakafanana neyakagadzirwa here?

Kwete. Cast metal inogadzirwa nekudira simbi yakanyungudutswa muforoma, uye inoita kunge ine zviyo zvakakura uye porosity yakawanda.

Ndechipi chiri nani chekudzivirira ngura?

Corrosion kuramba kunoenderana nekuumbwa kwezvinhu. Nekudaro, zvinhu zvekunyepedzera zvinogona kupa nani kuramba mune dzimwe nharaunda nekuda kwekuderedzwa porosity.

Simbi inopfurwa yakasimba kudarika simbi yakapfurwa here?

Kazhinji kwete. Simbi yefodhi yakasimba nekuda kwekugadzirisa zviyo zviri nani uye hurema hushoma hwemukati.

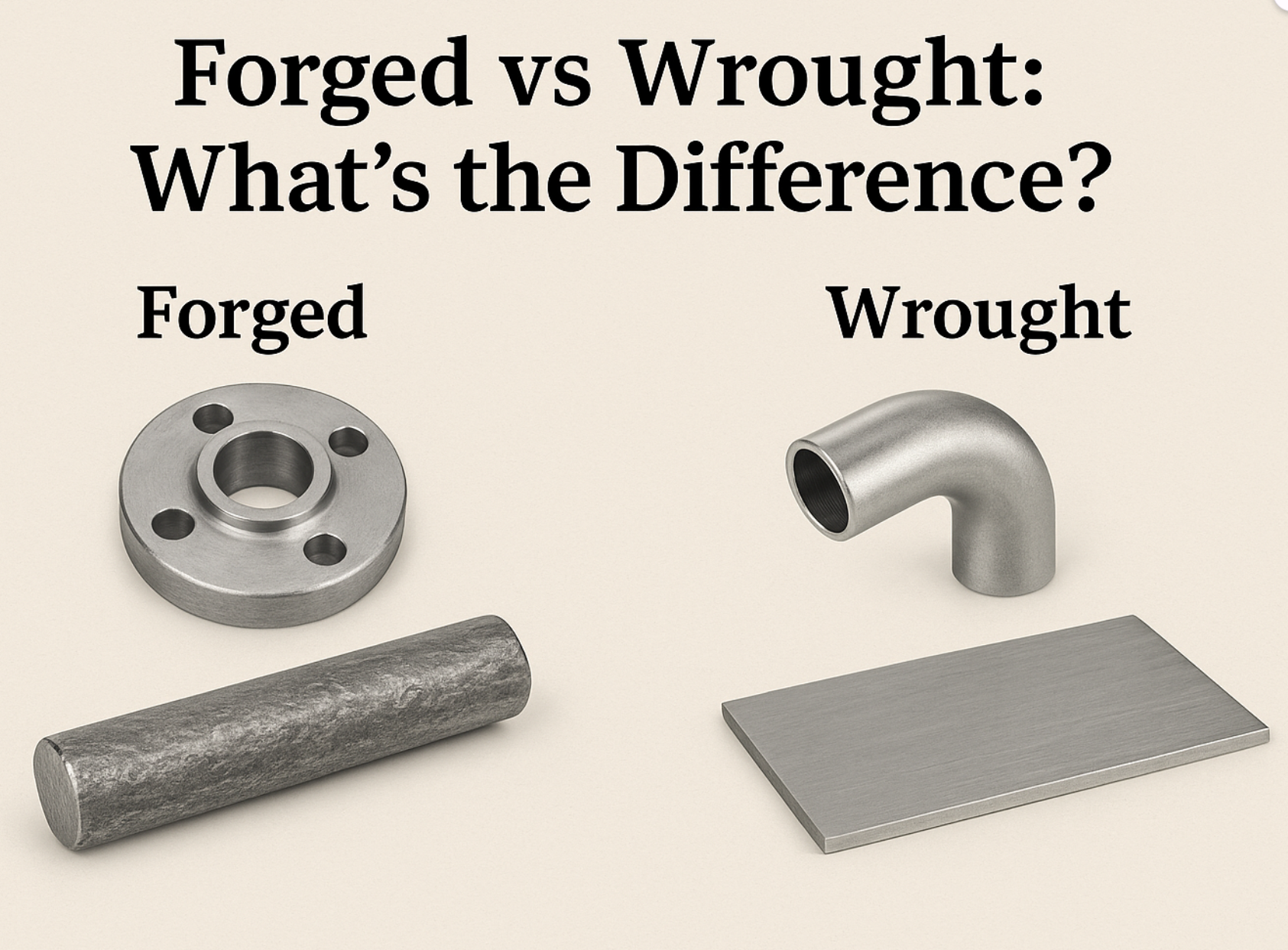

9. Kuenzanisa Kwekuona: Forged vs Wrought Metal Products

(Batanidza mufananidzo wekuenzanisa unoratidza flange yakaumbwa uye tsvimbo vs yakagadzirwa gokora uye shiti)

10. Mhedziso: Ziva Simbi Yako, Sarudza Nechivimbo

Kunzwisisa mutsauko pakati pesimbi dzakagadzirwa uye dzakagadzirwa kwakakosha muinjiniya uye maindasitiri ekushandisa. Zvinhu zvakaumbwa zvinopa simba repamusoro, kuramba kuneta, uye chimiro chezviyo, zvichiita kuti zvive zvakanaka kune zvakanyanya-kushushikana zvikamu. Zvikamu zvinogadzirwa, kune rumwe rutivi, zvinopa mutengo-kushanda, kufanana, uye kuumbwa kwakanakisa kwekushandiswa kwese.

Paunenge uchisarudza zvigadzirwa zvesimbi zvepurojekiti yako, gara uchifunga:

- Application environment

- Inodiwa mechanical properties

- Indasitiri mitemo

- Kugadzira bhajeti

Kunyangwe uri kutsvaga simbi isina simbi inopinza kana simbi dzegokora, kuziva mamiriro ekugadzira - ekugadzira kana kugadzirwa - kunobatsira kuve nechokwadi chekuti unosarudza simbi chaiyo, nekuita kwayo, nemutengo wakakodzera.

Nguva yekutumira: Jul-22-2025