Uma kuziwa ekukhiqizeni insimbi, amagama amabili avame ukuvela eceleni: akhiwe futhi akhiwe. Nakuba zingase zibonakale zifana ekuqaleni, zimelela izigaba ezimbili ezihlukene zokucutshungulwa kwensimbi ezinezici ezihlukile, izinzuzo zokusebenza, kanye nezicelo. Ukuqonda umehluko phakathi kwezinsimbi ezifojiwe neziqotshiwe kubalulekile konjiniyela, abakhiqizi, nabathengi lapho bekhetha into efanele ukuze bayisebenzise ngokuqondile.

Kulesi sihloko, sizohlola umehluko phakathi kwezinsimbi ezikhandwayo nezikhandiwe ngokwezincazelo, izinqubo zokukhiqiza, izakhiwo zemishini, amazinga, izibonelo zomkhiqizo, nokuningi.

1. Kusho ukuthini Forged in Metal Processing?

I-Forging yinqubo yokuguquguquka ehlanganisa ukusebenzisa amandla acindezelayo ensimbi, ngokuvamile emazingeni okushisa aphezulu, ukuyilolonga ibe yifomu oyifunayo. Ukufoja kungenziwa ngokushaya ngesando, ngokucindezela, noma ngokugingqa insimbi usebenzisa ama-dies.

Izici ezibalulekile ze-Forged Metal:

- Isakhiwo sokusanhlamvu esicwengisisiwe

- Amandla aphezulu kanye nokuqina

- Ukumelana nokukhathala okungcono

- Ama-voids ambalwa angaphakathi noma okufakiwe

Imikhiqizo Eqanjiwe Ejwayelekile:

- Ama-Flanges

- Imigodi

- Izindandatho

- Amagiya

- Izingxenye zomkhumbi wokucindezela

Izinhlobo Zokuqamba:

- I-Open-die Forging: Ilungele izingxenye ezinkulu.

- I-Closed-die (i-impression die) i-forging: Isetshenziselwa izimo ezinembe kakhudlwana.

- Ukufoja indandatho egoqiwe engenamthungo: Ivamise ukusetshenziswa ku-aerospace kanye nokukhiqiza amandla.

2. Iyini Insimbi Eyinsimbi?

Igama elithi “okwenziwayo” lisho insimbi eye yasetshenzwa yafakwa esimweni sayo sokugcina, ngokuvamile ngokugingqika, ukudweba, ukuyikhipha, noma ukufoja. Umbono oyinhloko ukuthi izinsimbi ezikhandiwe aziphonswa, okusho ukuthi azizange zithelwe ensimbi encibilikisiwe zibe isikhunta.

Izici ze-Wrought Metal:

- I-Ductile futhi ithambile

- Isakhiwo sokusanhlamvu esilinganayo

- Kulula ukwenza umshini nokushisela

- I-surface finish enhle

Imikhiqizo Ejwayelekile Esenziwe:

- Ipayipi kanye neshubhu

- Izindololwane nezinsika

- Ipuleti neshidi lensimbi

- Ucingo nezinduku

- Izimo zesakhiwo (i-I-beams, ama-engeli)

3. Umehluko Obalulekile Phakathi Kwezinsimbi Ezenziwa Nezibunjiwe

| Isici | I-Forged Metal | Insimbi Eyenziwe |

|---|---|---|

| Incazelo | Icindezelwe ngaphansi kwengcindezi ephezulu | Isebenza ngomshini kodwa ayifakwanga |

| Isakhiwo sokusanhlamvu | Kuqondaniswe futhi kwacwengwa | Iyunifomu kodwa iminyene kancane |

| Amandla | Amandla aphezulu kanye nokuqina | Amandla amaphakathi |

| Izinhlelo zokusebenza | Izingxenye ezinengcindezi ephezulu, ezinengcindezi ephezulu | Izicelo ezijwayelekile zesakhiwo |

| Inqubo | Forging press, isando, fa | Ukugingqa, ukudweba, ukukhipha |

| Izindleko | Iphakeme ngenxa yamathuluzi namandla | Ukonga okuningi ngamanani amakhulu |

| I-Surface Qeda | Indawo eqinile (ingenziwa ngomshini) | Ngokuvamile bushelelezi |

4. Amazinga kanye Nezitifiketi

Imikhiqizo Eqanjiwe:

- I-ASTM A182 (Ingxubevange Efojiwe noma Egingqelwe kanye namaFlange Epayipi Lensimbi Engagqwali)

- I-ASTM B564 (I-Nickel Alloy Forgings)

- I-ASME B16.5 / B16.47 (AmaFlange Afojiwe)

Imikhiqizo Esenziwe:

- I-ASTM A403 (Okufakwayo Kwepayipi Lensimbi Engagqwali ye-Austenitic)

- I-ASTM A240 (I-Wrought Stainless Steel Plate, Ishidi, kanye Nomucu)

- I-ASTM A554 (I-Welded Stainless Stainless Mechanical Tubing)

5. Iyiphi Okufanele Uyikhethe: Eyakhiwe Noma Yenziwe?

Ukukhetha phakathi kwensimbi ekhandiwe nekhandiwe kuncike kakhulu ezidingweni zokufaka isicelo:

Khetha insimbi efojiwe lapho:

- Ingxenye ingaphansi kwengcindezi ephezulu noma ingcindezi (isb., ama-flange anengcindezi ephezulu, ama-shaft abalulekile)

- Kudingeka amandla aphakeme nokumelana nokukhathala

- Ubuqotho be-Dimensional bubalulekile ngaphansi komthwalo

Khetha insimbi ekhandiwe lapho:

- Ingxenye ayizwani nokulayisha ngokweqile

- Ukushisekela nokushisela kubalulekile

- Ukukhiqizwa kwevolumu ephezulu kuyadingeka ngezindleko eziphansi

6. Izicelo Zemboni

| Imboni | Imikhiqizo Eqanjiwe | Imikhiqizo Esetshenzisiwe |

| Amafutha Negesi | Ama-valve anengcindezi ephezulu, ama-flanges | Ukufakwa kwamapayipi, izindololwane |

| I-Aerospace | Izingxenye zenjini ye-jet, amadiski e-turbine | Amaphaneli esakhiwo, abakaki |

| Ezezimoto | Ama-Crankshafts, izinduku zokuxhuma | Amaphaneli womzimba, amashubhu wokukhipha amandla |

| Ukukhiqiza Amandla | Ama-turbine rotors, izindandatho | Amashubhu e-Condenser, insimbi yeshidi |

| Ukwakha | Amalunga okuthwala imithwalo | Imishayo, amaphrofayili esakhiwo |

7. Imibono Yensimbi: Kungani Ukuqamba Kwenza Insimbi Iqine Kakhudlwana

I-Forging ilungisa kabusha ukugeleza kokusanhlamvu ukuze ilandele ukuma kwengxenye, isusa ukungaqhubeki nemingcele yokusanhlamvu esebenza njengamaphoyinti abuthakathaka. Lokhu kulungiswa okusanhlamvu kwenza izingxenye ezifojiwe zibe namandla kakhulu futhi zithembeke kakhulu ezindaweni ezizwelayo ukukhathala.

Izinto ezisakhiwe nazo ziyazuza ekusebenzeni kwemishini, kodwa isakhiwo sangaphakathi asilungiseki kangako kunezingxenye ezifojiwe.

8. Imibuzo Evame Ukubuzwa Ngensimbi Efojiwe Neyinsimbi

Ingabe insimbi ingakhandwa futhi yenziwe?

Yebo. "Okwenziwe" kuchaza isimo esijwayelekile sokusetshenzwa ngepulasitiki, futhi ukuqamba kuwuhlobo olulodwa lwenqubo eyenziwe.

Ingabe i-cast metal iyafana neyakhiwe?

Cha. I-Cast metal yenziwa ngokuthela insimbi encibilikisiwe esikhunjeni, futhi ijwayele ukuba nezinhlaka ezinkudlwana zokusanhlamvu kanye ne-porosity eyengeziwe.

Ikuphi okungcono ukumelana nokugqwala?

Ukumelana nokugqwala kuncike ekwakhiweni kwezinto. Kodwa-ke, izinto ezibunjiwe zinganikeza ukumelana okungcono kwezinye izindawo ngenxa yokuncipha kwe-porosity.

Ingabe insimbi ekhandiwe inamandla kunensimbi ebunjiwe?

Ngokujwayelekile cha. Insimbi efojiwe inamandla ngenxa yokuqondanisa okusanhlamvu okungcono kanye nokukhubazeka okumbalwa kwangaphakathi.

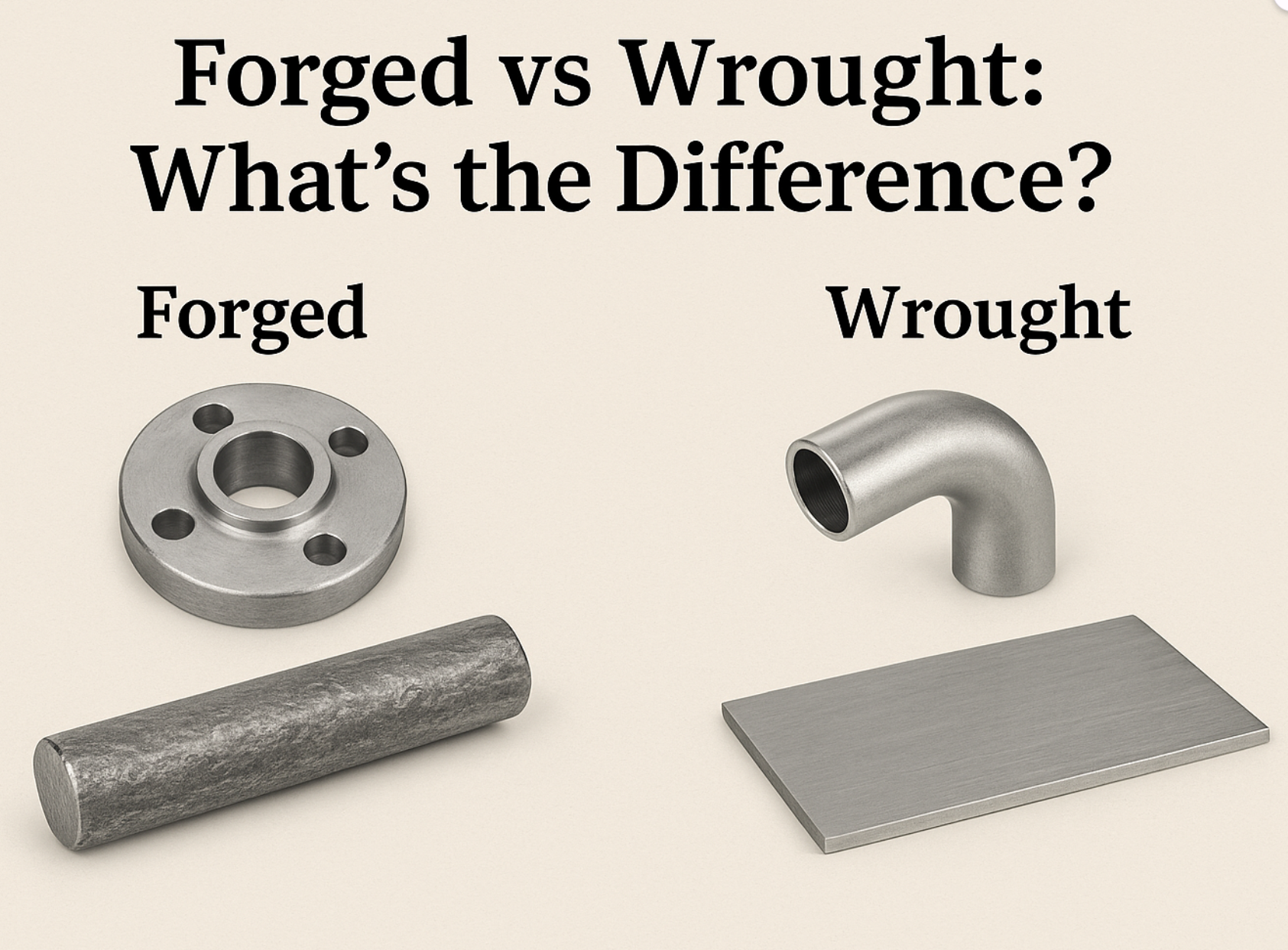

9. Ukuqhathanisa Okubonakalayo: Imikhiqizo Yensimbi Efojiwe vs Eyokhiwe

(Faka phakathi isithombe esiqhathanisayo esibonisa iflenge elifojiwe kanye nenduku vs indololwane neshidi)

10. Isiphetho: Yazi Insimbi Yakho, Khetha Ngokuzethemba

Ukuqonda umehluko phakathi kwezinsimbi ezikhandwayo neziqotshiwe kubalulekile ezinhlelweni zobunjiniyela nezimboni. Izingxenye ezakhiwe zinikeza amandla aphakeme, ukumelana nokukhathala, kanye nesakhiwo sokusanhlamvu, okuzenza zilungele izingxenye ezinengcindezi ephezulu. Izingxenye ezisetshenzisiwe, ngakolunye uhlangothi, zinikeza ukusebenza kahle kwezindleko, ukufana, kanye nokwakheka okuhle kakhulu kokusetshenziswa okuvamile.

Lapho ukhetha imikhiqizo yensimbi yephrojekthi yakho, cabanga njalo:

- Indawo yohlelo lokusebenza

- Izakhiwo ezidingekayo zemishini

- Izindinganiso zezimboni

- Isabelomali sokukhiqiza

Kungakhathaliseki ukuthi ufuna ama-flange ensimbi engagqwali noma ukufakwa kwendololwane, ukwazi ingemuva lokukhiqiza—elifojiwe noma elenziwe—kusiza ekuqinisekiseni ukuthi ukhetha insimbi efanele, ngokusebenza okulungile, ngezindleko ezifanele.

Isikhathi sokuthumela: Jul-22-2025