Xa kuziwa kwimveliso yesinyithi, amagama amabini ahlala ebonakala esecaleni: yenziwe kwaye yenziwe. Nangona zinokubonakala zifana xa uqala, zimele iindidi ezimbini ezahlukeneyo zokusetyenzwa kwesinyithi ezineempawu ezizodwa, iingenelo zokusebenza, kunye nokusetyenziswa. Ukuwuqonda umahluko phakathi kweentsimbi ezikhandiweyo kunye nezakhiweyo kubalulekile kwiinjineli, abavelisi, kunye nabathengi xa bekhetha imathiriyeli efanelekileyo yokusetyenziswa kwabo.

Kweli nqaku, siza kuphonononga umahluko phakathi kweentsimbi ezibunjiweyo kunye nezakhiwe ngokweenkcazo, iinkqubo zokuvelisa, iipropathi zoomatshini, imigangatho, imizekelo yemveliso, kunye nokunye.

1. Ithetha ntoni iForged kwiMetal Processing?

Ukuqulunqa yinkqubo yokuguqula ebandakanya ukusebenzisa amandla oxinzelelo kwintsimbi, ngokuqhelekileyo kumaqondo obushushu aphezulu, ukuyibumba ibe yifom efunwayo. Ukubunjwa kunokwenziwa ngokubethelwa, ukucinezela, okanye ukuqengqeleka kwentsimbi usebenzisa iidiyezi.

Iimpawu eziphambili zeMetal Forged:

- Ulwakhiwo olusulungekileyo lweenkozo

- Amandla aphezulu kunye nokuqina

- Ngcono ukumelana nokudinwa

- I-voids encinci yangaphakathi okanye i-inclusions

Iimveliso zoMgangatho eziqhelekileyo:

- Iiflange

- Iishafu

- Iringi

- Iigiya

- Amacandelo enqanawa yoxinzelelo

Iindidi Zokwenza:

- Open-die forging: Ilungele amacandelo amakhulu.

- Closed-die (impression die) forging: Isetyenziselwa iimilo ezichanekileyo ngakumbi.

- Iringi esongiweyo engenamthungo: Ihlala isetyenziswa kwi-aerospace kunye nokuveliswa kwamandla.

2. Yintoni Intsimbi Eyotyiweyo?

Igama elithi “intsimbi” libhekisela kwisinyithi esiye sasetyenzwa ngoomatshini sade sayigqibezela, ngokuqhelekileyo ngokuqengqeleka, ukuzoba, ukukhutshelwa, okanye ukubunjwa. Ingcamango ephambili yeyokuba iintsimbi ezikhandiweyo aziphoswanga, nto leyo ethetha ukuba azizange zigalelwe kwisinyithi esinyibilikisiweyo zibe ngumngundo.

Iimpawu zeNtsimbi eQiweyo:

- I-Ductile kunye ne-malleable

- Ubume obufanayo beenkozo

- Kulula kumatshini kunye ne-weld

- Ukugqitywa kakuhle komphezulu

Iimveliso eziqhelekileyo:

- Umbhobho kunye netyhubhu

- Iingqiniba kunye nee tees

- Ipleyiti kunye nentsimbi yentsimbi

- Ucingo kunye neentonga

- Iimilo zesakhiwo (i-I-beams, ii-engile)

3. Iiyantlukwano eziphambili phakathi kweentsimbi ezibunjiweyo nezibunjiweyo

| Uphawu | Isinyithi sokwenziwa | Isinyithi esisebenzayo |

|---|---|---|

| Ingcaciso | Icinezelwe phantsi koxinzelelo oluphezulu | Isebenza ngoomatshini kodwa ayiphoswanga |

| Ulwakhiwo lweenkozo | Ilungelelanisiwe kwaye isulungekile | Iyunifomu kodwa ixinene kancinci |

| Amandla | Amandla aphezulu kunye nokuqina | Amandla aphakathi |

| Usetyenziso | Uxinzelelo oluphezulu, iindawo ezinoxinzelelo oluphezulu | Ukusetyenziswa kolwakhiwo ngokubanzi |

| Inkqubo | Forging press, ihamile, fa | Ukuqengqeleka, ukuzoba, ukukhupha |

| Iindleko | Ephakamileyo ngenxa yezixhobo kunye namandla | Uqoqosho ngakumbi ngobuninzi |

| Umphezulu Gqiba | Umphezulu orhabaxa (ungatshintshwa) | Ngokubanzi umphezulu ogudileyo |

4. Imigangatho kunye neziQinisekiso

Iimveliso zomgunyathi:

- I-ASTM i-A182 (Ingxubevange eQonxiweyo okanye eQingiweyo kunye neeFlentshi zemibhobho yentsimbi engatyiwayo)

- I-ASTM B564 (i-Nickel Alloy Forgings)

- I-ASME B16.5 / B16.47 (IiFlange zoMgangatho)

Iimveliso eziSebenzisiweyo:

- I-ASTM A403 (Izifakelo zemibhobho yentsimbi egqwethiweyo yeAustenitic)

- I-ASTM A240 (Ipleyiti yentsimbi egqwethiweyo, iPhepha, kunye nomtya)

- I-ASTM A554 (iTubing yoomatshini eWeldless Steel Steel)

5. Yeyiphi omele uyikhethe: yenzelwe okanye yenziwe?

Ukukhetha phakathi kwentsimbi ekhandiweyo kunye nekhandiweyo kuxhomekeke kakhulu kwiimfuno zesicelo:

Khetha intsimbi ebunjiweyo xa:

- Inxalenye iphantsi koxinzelelo oluphezulu okanye uxinzelelo (umzekelo, iiflange zoxinzelelo oluphezulu, iishafts ezibalulekileyo)

- Amandla aphezulu kunye nokumelana nokudinwa kuyafuneka

- Imfezeko yomgangatho ibalulekile phantsi komthwalo

Khetha intsimbi ekhandiweyo xa:

- Icandelo alifumani ukulayisha okugqithisileyo

- I-machinability kunye ne-weldability ibalulekile

- Imveliso yomthamo ophezulu iyafuneka ngexabiso eliphantsi

6. Izicelo zoShishino

| Ishishini | Iimveliso zoMgangatho | Iimveliso ezenziweyo |

| I-oyile neGesi | Iivalve zoxinzelelo oluphezulu, iiflange | Ukufakwa kwemibhobho, iingqiniba |

| I-Aerospace | Amalungu enjini yeJet, iidiski zeinjini yomoya | Iiphaneli zesakhiwo, izibiyeli |

| Iimoto | IiCrankshafts, iintonga zokudibanisa | Iipaneli zomzimba, i-exhaust tubing |

| IsiZukulwana saMandla | I-rotors ye-turbine, amakhonkco | Iityhubhu zeCondenser, sheet sheet |

| Ukwakhiwa | Amalungu okuthwala umthwalo | Imiqadi, iiprofayili zesakhiwo |

7. I-Metallurgical Insights: Kutheni i-Forging yenza isinyithi esinamandla

Ukubunjwa kulungelelanisa ukuhamba okuziinkozo ukulandela ubume benxalenye, kuphelisa ukungaqhubeki kunye nemida yengqolowa esebenza njengamanqaku abuthathaka. Oku kucocwa kweenkozo kwenza amacandelo abunjiweyo abe namandla kakhulu kwaye athembeke ngakumbi kwiindawo ezibuthathaka.

Izixhobo ezigrunjiweyo zikwaxhamla ekusebenzeni ngoomatshini, kodwa ulwakhiwo lwangaphakathi alunakwenziwa ngcono kuneendawo ezibunjiweyo.

8. FAQs Malunga Metal Forged and Wrought

Ngaba isinyithi sinokukhatywa kunye nokusebenza?

Ewe. "I-Wrought" ichaza imeko jikelele yokusetyenzwa kweplastiki, kwaye ukubunjwa lunye uhlobo lwenkqubo eyenziweyo.

Ngaba intsimbi etyhidiweyo iyafana naleyo yenziweyo?

Hayi iCast metal yenziwe ngokugalela isinyithi esinyibilikisiweyo kumngundo, kwaye ithande ukuba nezakhiwo ezinkulu zengqolowa kunye ne-porosity ngaphezulu.

Yeyiphi eyona ingcono kuxhathiso lokutya?

Ukumelana nokubola kuxhomekeke ekubunjweni kwezinto eziphathekayo. Nangona kunjalo, izinto ezibunjiweyo zinokunika ukuchasana okungcono kwezinye iindawo ngenxa yokuncipha kwe-porosity.

Ngaba intsimbi ekhandiweyo yomelele kunentsimbi ebunjiweyo?

Ngokuqhelekileyo akukho. Insimbi eyenziweyo yomelele ngenxa yokulungelelaniswa okungcono kweenkozo kunye neziphene ezimbalwa zangaphakathi.

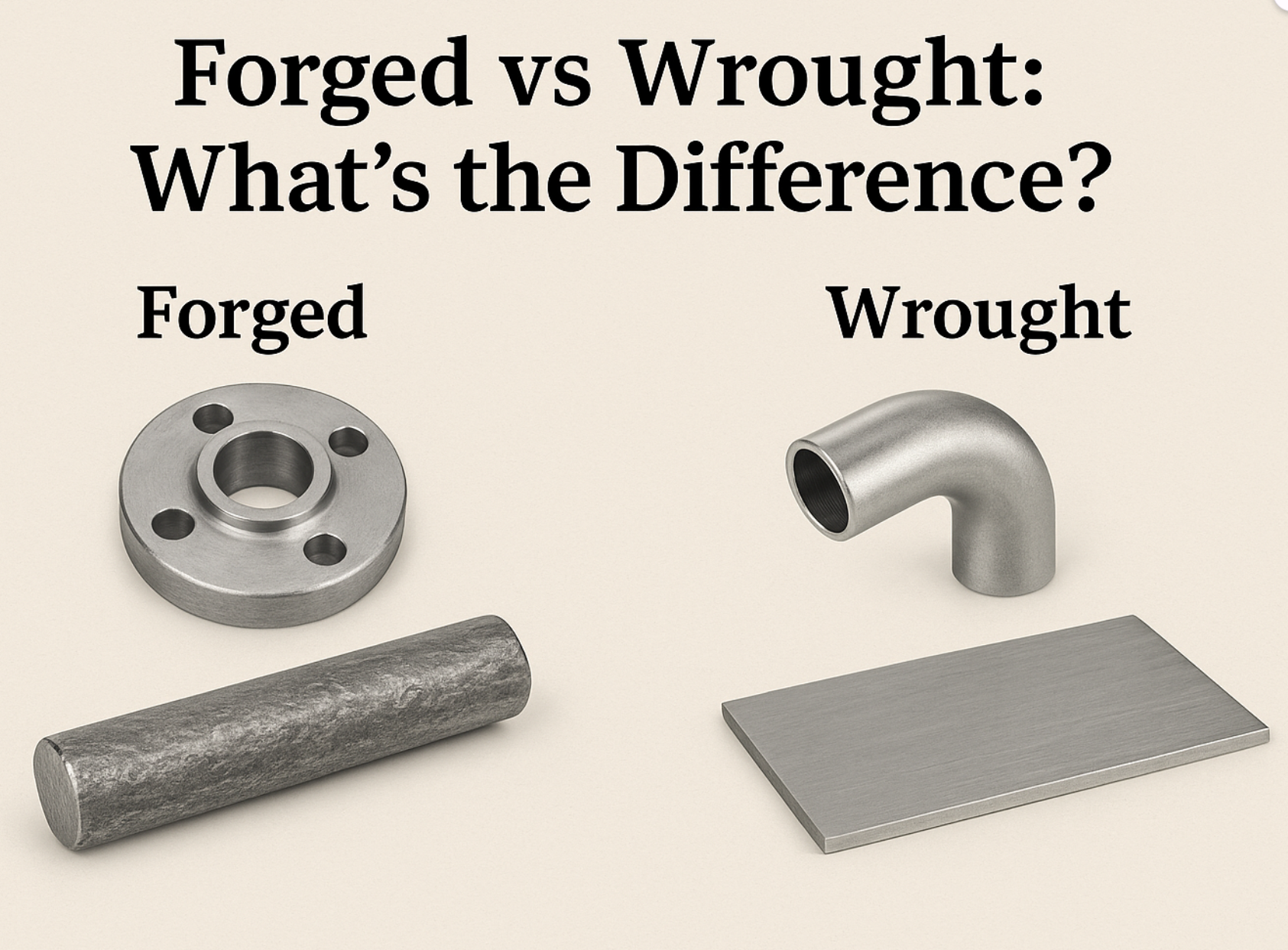

9. Uthelekiso oluBonakalayo: IiMveliso zeMetal ezibunjiweyo ezibunjiweyo nezakhiweyo

(Bandakanya uthelekiso lomfanekiso obonisa iflenge yomgunyathi kunye nentonga vs ingqiniba eyenziweyo kunye neshiti)

10. Isiphelo: Yazi iMetal yakho, Khetha ngokuzithemba

Ukuqonda umahluko phakathi kweentsimbi ezikhandiweyo kunye nezo zikhandiweyo kubalulekile kubunjineli nakwizicelo zemizi-mveliso. Amacandelo abunjiweyo anika amandla aphezulu, ukumelana nokudinwa, kunye nokwakheka kweenkozo, ezenza zilungele iindawo ezinoxinzelelo oluphezulu. Amacandelo asetyenzisiweyo, kwelinye icala, abonelela ngeendleko ezifanelekileyo, ukufana, kunye nokwakheka okugqwesileyo kokusetyenziswa ngokubanzi.

Xa ukhetha iimveliso zetsimbi kwiprojekthi yakho, hlala ucinga:

- Indawo yosetyenziso

- Iimpawu ezifunekayo zoomatshini

- Imigangatho yeshishini

- Uhlahlo lwabiwo-mali lwemveliso

Nokuba ukhangela iiflange zentsimbi engatyiwayo okanye izifakelo zengqiniba, ukwazi imvelaphi yemveliso-yenziwe ngomyidi okanye eyenziweyo-kunceda ukuqinisekisa ukuba ukhetha intsimbi eyiyo, kunye nokusebenza okulungileyo, ngexabiso elifanelekileyo.

Ixesha lokuposa: Jul-22-2025