I ka wā e pili ana i ka hana metala, ʻike pinepine ʻia nā huaʻōlelo ʻelua i ka ʻaoʻao: forged a wrought. ʻOiai ua like paha lākou i ka nānā mua ʻana, hōʻike lākou i ʻelua mau ʻāpana ʻokoʻa o ka hana metala me nā hiʻohiʻona kūʻokoʻa, nā pono hana, a me nā noi. ʻO ka hoʻomaopopo ʻana i ka ʻokoʻa ma waena o nā metala forged a me wrought metala he mea nui ia no nā ʻenekinia, nā mea hana, a me nā mea kūʻai aku i ke koho ʻana i nā mea kūpono no kā lākou hoʻohana kikoʻī.

Ma kēia ʻatikala, e ʻimi mākou i nā ʻokoʻa ma waena o nā metala forged a me wrought me ka wehewehe ʻana, nā kaʻina hana, nā waiwai mechanical, nā kūlana, nā hiʻohiʻona huahana, a me nā mea hou aku.

1. He aha ka manaʻo o Forged i ka hana ʻana metala?

ʻO ka hoʻopaʻa ʻana he kaʻina hana hoʻololi e pili ana i ka hoʻopili ʻana i nā ikaika compressive i ka metala, maʻamau i nā wela kiʻekiʻe, e hoʻolike ai i ke ʻano i makemake ʻia. Hiki ke hana ʻia ma ka hāmare, kaomi ʻana, a i ʻole ka ʻōwili ʻana i ka metala me ka hoʻohana ʻana i nā mea make.

ʻO nā hiʻohiʻona nui o Forged Metal:

- ʻO ke ʻano o ka palaoa i hoʻomaʻemaʻe ʻia

- Ka ikaika kiʻekiʻe a me ka paʻakikī

- ʻOi aku ka maikaʻi o ka pale ʻana i ka luhi

- Liʻiliʻi nā hakahaka o loko a i ʻole nā mea hoʻokomo

Nā mea hana maʻamau i hoʻopaʻa ʻia:

- ʻO nā lehelehe

- Nā lāʻau

- Na apo

- Na Gears

- ʻO nā ʻāpana moku kaomi

Nā ʻano o ka hana ʻana:

- Wehe-make forging: He kūpono no nā mea nui.

- Paʻa-make (impression die) forging: Hoʻohana ʻia no nā ʻano kikoʻī.

- Hoʻohana pinepine ʻia i ka aerospace a me ka hana mana.

2. He aha ka Metala Hana ʻia?

ʻO ka huaʻōlelo "wrought" e pili ana i ka metala i hana ʻia me ka mīkini i kona ʻano hope, maʻamau ma ka ʻōwili ʻana, ke kaha kiʻi, ka hoʻokuʻu ʻana, a i ʻole ke kala ʻana. ʻO ka manaʻo nui, ʻaʻole i hoʻolei ʻia nā metala i hana ʻia, ʻo ia hoʻi, ʻaʻole i ninini ʻia mai ka metala i hoʻoheheʻe ʻia i loko o nā mole.

ʻO nā hiʻohiʻona o ke kila kila:

- ʻOluʻu a malleable

- ʻO ke ʻano o ka palaoa kūlike

- ʻOi aku ka maʻalahi o ka mīkini a weld

- ʻO ka hoʻopau ʻili maikaʻi

Nā huahana i hana maʻamau:

- Paipu a me ka paipu

- Nā kuʻekuʻe lima a me nā kī

- Papa a me ka lau metala

- Uea a me na kookoo

- Nā ʻano hiʻona (I-beams, nā kihi)

3. Nā ʻokoʻa koʻikoʻi ma waena o nā metala paʻa a me nā metala i hana ʻia

| Hiʻona | Metala Paʻa | Metala Hana ʻia |

|---|---|---|

| Wehewehe | Hoʻopili ʻia ma lalo o ke kaomi kiʻekiʻe | Hana ʻia me ka mīkini akā ʻaʻole hoʻolei |

| Kūʻai palaoa | Kūlike a hoʻomaʻemaʻe ʻia | Kaulike akā ʻaʻole paʻa |

| Ka ikaika | ʻOi aku ka ikaika a me ka paʻakikī | Ka ikaika haʻahaʻa |

| Nā noi | ʻO nā'āpana kiʻekiʻe, kiʻekiʻe-koʻikoʻi | Nā noi hoʻolālā maʻamau |

| Kaʻina hana | Paʻi forging, hamare, make | ʻO ka ʻōwili ʻana, ke kaha kiʻi ʻana, ka extruding |

| Koina | Kiʻekiʻe ma muli o ka mea hana a me ka ikehu | ʻOi aku ka waiwai i nā mea nui |

| Hoʻopau ʻili | ʻOi aku ka ʻili (hiki ke hana ʻia) | ʻO ka ʻili maʻamau |

4. Nā Kūlana a me nā palapala hōʻoia

Nā huahana i hoʻopaʻa ʻia:

- ASTM A182 (Forged or Rolled Alloy and Stainless Steel Pipe Flanges)

- ASTM B564 (Nickel Alloy Forgings)

- ASME B16.5 / B16.47 (Nā Paʻa Paʻa)

Nā huahana i hana ʻia:

- ASTM A403 (Wrought Austenitic Stainless Steel Pipe Fitings)

- ASTM A240 (Papa kila kuʻi ʻole ʻia, Pepa, a me ke kāʻei)

- ASTM A554 (Welded Stainless Steel Mechanical Tubing)

5. ʻO wai ka mea āu e koho ai: Forged or Wrought?

ʻO ka koho ma waena o ka forged and wrought metala e hilinaʻi nui ʻia i nā koi noi:

E koho i ka metala forged inā:

- Aia ka ʻāpana i ke koʻikoʻi kiʻekiʻe a i ʻole ke kaomi (e laʻa, nā flanges kiʻekiʻe, nā kumu koʻikoʻi)

- Pono ka ikaika kiʻekiʻe a me ke kūpaʻa luhi

- He mea koʻikoʻi ka pono o ke ana ma lalo o ka ukana

E koho i ka metala i hana ʻia inā:

- ʻAʻole ʻike ka ʻāpana i ka hoʻouka ʻana

- He mea nui ka machinability a me ka weldability

- Pono ka hana kiʻekiʻe ma ke kumu kūʻai haʻahaʻa

6. Nā noi ʻoihana

| ʻOihana | Nā Huahana Hana ʻia | Nā Huahana Hana ʻia |

| Aila & Gas | Kiʻekiʻe-press valves, flanges | Paipu paipu, kuʻekuʻe lima |

| Aerospace | Nā ʻāpana ʻenekini jet, nā diski turbine | Nā panela hale, nā pale |

| Kaʻa kaʻa | Crankshafts, nā lāʻau hoʻohui | Nā panela kino, paipu hoʻopau |

| Hoʻoulu mana | Turbine rotors, apo | Nā paipu condenser, pepa metala |

| Kūkulu | ʻO nā hui haʻahaʻa | Nā lāʻau kaola, nā ʻaoʻao hoʻolālā |

7. Nā Manaʻo Metallurgical: No ke aha e hoʻoikaika ai ka hoʻopaʻa ʻana i ke metala

Hoʻoponopono hou ka Forging i ke kahe o ka palaoa e hahai i ke ʻano o ka ʻāpana, e hoʻopau ana i nā discontinuities a me nā palena o ka palaoa e hana ma ke ʻano nāwaliwali. ʻO kēia hoʻomaʻemaʻe palaoa e ʻoi aku ka ikaika a ʻoi aku ka hilinaʻi i nā ʻāpana forged.

Loaʻa nā mea i hana ʻia mai ka hana mechanical, akā ʻoi aku ka maikaʻi o ka hoʻolālā o loko ma mua o nā ʻāpana i hoʻopaʻa ʻia.

8. Nā nīnau nīnau e pili ana i nā metala paʻa a me ka hana ʻana

Hiki ke kalai ʻia a hana ʻia ke metala?

ʻAe. Hōʻike ʻo "Wrought" i ke ʻano maʻamau o ka hana plastically, a ʻo ka forging kekahi ʻano o ke kaʻina hana.

Ua like anei ka metala hoolei me ka hanaia?

ʻAʻole. Hana ʻia ka metala hoʻoheheʻe ma ka ninini ʻana i ka metala i hoʻoheheʻe ʻia i loko o kahi mole, a ʻoi aku ka nui o nā hale palaoa a ʻoi aku ka porosity.

ʻO wai ka maikaʻi no ka pale ʻana i ka corrosion?

ʻO ke kūpaʻa ʻana o ka corrosion e pili ana i ka haku mele. Eia nō naʻe, hiki ke hāʻawi aku i nā mea i hoʻopaʻa ʻia ke kūʻē maikaʻi i kekahi mau kaiapuni ma muli o ka emi ʻana o ka porosity.

Ua ʻoi aku ka ikaika o ke kila hana ʻia ma mua o ke kila hoʻoheheʻe ʻia?

ʻAʻole maʻamau. ʻOi aku ka ikaika o ke kila forged no ka maikaʻi o ka hoʻopololei ʻana i ka palaoa a me ka liʻiliʻi o nā hemahema o loko.

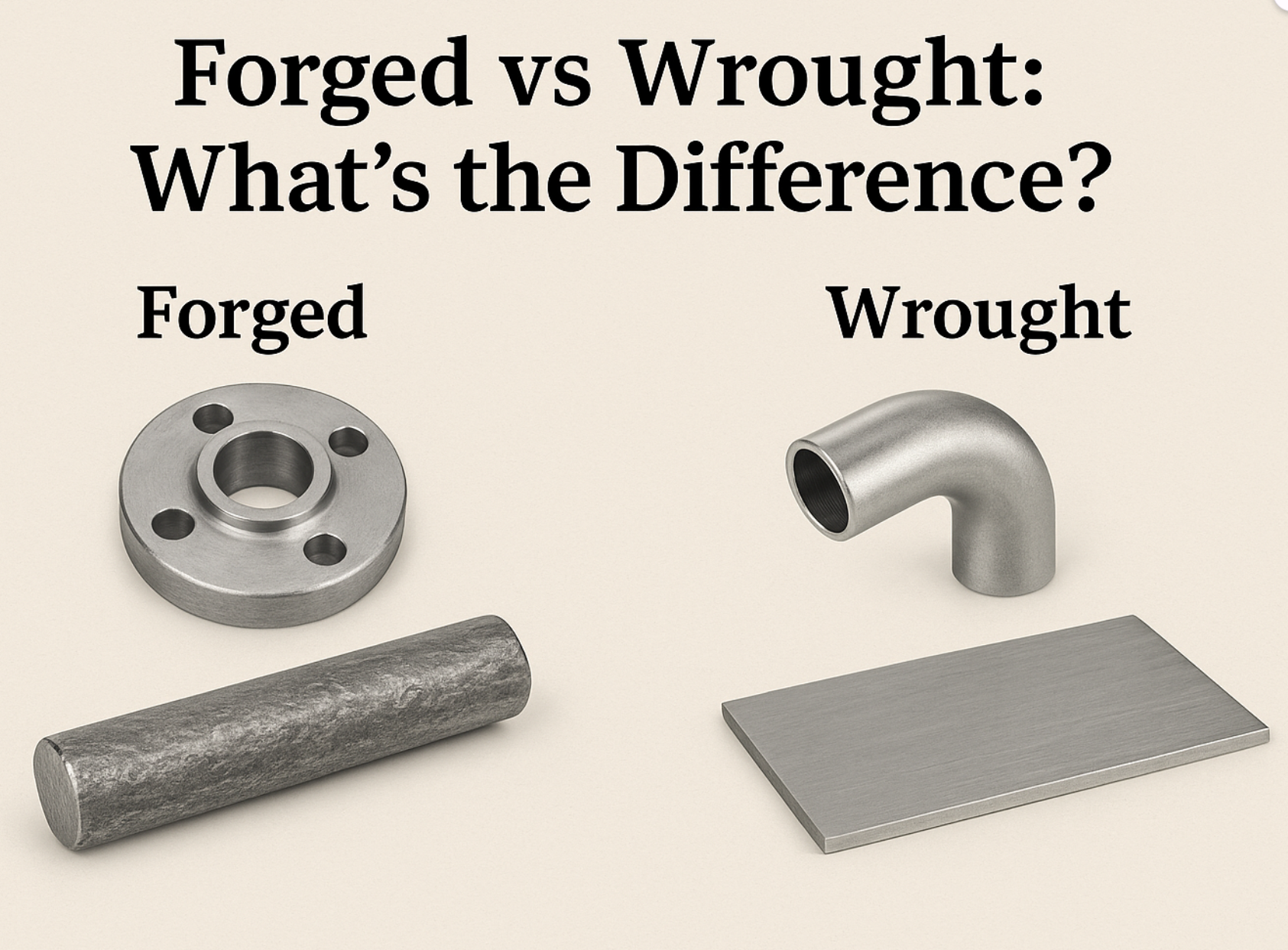

9. Hoʻohālikelike Nānā: Forged vs Wrought Metal Products

(Hoʻohui i ke kiʻi hoʻohālikelike e hōʻike ana i ka flange forged and rod vs wrought elbow and sheet)

10. Ka hopena: E ʻike i kāu Metal, E koho me ka hilinaʻi

He mea koʻikoʻi ka hoʻomaopopo ʻana i ka ʻokoʻa ma waena o nā metala forged a me wrought i ka ʻenehana a me nā noi ʻoihana. Hāʻawi nā ʻāpana forged i ka ikaika kiʻekiʻe, ka pale ʻana i ka luhi, a me ke ʻano o ka palaoa, e hoʻolilo iā lākou i mea kūpono no nā ʻāpana koʻikoʻi. ʻO nā mea hana i hana ʻia, ma ka ʻaoʻao ʻē aʻe, hāʻawi i ka uku-efficiency, uniformity, a me ka formability maikaʻi loa no ka hoʻohana maʻamau.

Ke koho ʻana i nā huahana metala no kāu papahana, e noʻonoʻo mau:

- Kaiapuni noi

- Pono nā waiwai mechanical

- Nā kūlana ʻoihana

- Puke kālā hana

Inā ʻoe e ʻimi nei i nā flanges stainless steel a i ʻole nā kuʻekuʻe kuʻekuʻe, ʻo ka ʻike ʻana i ke ʻano o ka hana ʻana—i hoʻopaʻa ʻia a i hana ʻia paha—e kōkua iā ʻoe e koho i ka metala kūpono, me ka hana kūpono, ma ke kumu kūʻai kūpono.

Ka manawa hoʻouna: Iulai-22-2025