Ha ho tluoa tabeng ea tlhahiso ea tšepe, mantsoe a mabeli a atisa ho hlaha ka mahlakoreng a mabeli: a entsoeng le a entsoeng. Leha li ka bonahala li tšoana qalong, li emela mekhahlelo e 'meli e fapaneng ea ts'ebetso ea tšepe e nang le litšobotsi tse ikhethang, melemo ea ts'ebetso le ts'ebeliso. Ho utloisisa phapang pakeng tsa litšepe tse entsoeng le tse entsoeng ho bohlokoa ho baenjiniere, bahlahisi le bareki ha ba khetha thepa e nepahetseng bakeng sa tšebeliso ea bona e khethehileng.

Sehloohong sena, re tla hlahloba phapang lipakeng tsa litšepe tse entsoeng le tse entsoeng ho latela litlhaloso, lits'ebetso tsa tlhahiso, thepa ea mochini, litekanyetso, mehlala ea lihlahisoa le tse ling.

1. Forged e Bolela'ng ka Metal Processing?

Forging ke mokhoa oa deformation o kenyelletsang ho sebelisa matla a khatello ho tšepe, hangata ka mocheso o phahameng, ho e bopa hore e be sebopeho se lakatsehang. Ho qhekella ho ka etsoa ka ho otla ka hamore, ho hatella kapa ho phutholla tšepe ka ho sebelisa dies.

Lintlha tsa bohlokoa tsa Forged Metal:

- Sebopeho sa lijo-thollo se hloekisitsoeng

- Matla a phahameng le ho tiea

- Ho hanyetsa mokhathala ho molemo

- Li-voids tse fokolang tsa ka hare kapa tse kenyelletsoeng

Lihlahisoa tse Tloaelehileng tsa Forged:

- Li-flange

- Mekotlo

- Mehele

- Li-gears

- Likarolo tsa sekepe sa khatello

Mefuta ea ho qhekella:

- Open-die forging: E loketse likarolo tse kholo.

- Closed-die (impression die) forging: E sebelisoa bakeng sa libopeho tse nepahetseng haholoanyane.

- Mechini e phuthetsoeng e se nang seamless: Hangata e sebelisoa sebakeng sa sefofane le ho fehla motlakase.

2. Metal e Otloang ke Eng?

Poleloana e reng “sebelisoa” e bolela tšepe e ’nileng ea sebetsoa hore e be sebopeho sa eona sa ho qetela, hangata ka ho bilika, ho toroa, ho e ntša kapa ho betla. Taba ea bohlokoa ke hore litšepe tse betliloeng ha li tšeloe, ho bolelang hore ha lia ka tsa tšeloa ka tšepe e qhibilihisitsoeng ho ea ka har'a hlobo.

Litšobotsi tsa Metal e Otliloeng:

- Ductile le bonolo

- Sebopeho sa lijo-thollo tse tšoanang

- Ho bonolo ho etsa mochini le ho cheselletsa

- Qetello e ntle ea bokaholimo

Lihlahisoa tse Tloaelehileng:

- Pipe le tubing

- Li-elbows le li-tee

- Letlapa le lakane tšepe

- Mohala le melamu

- Libopeho tsa sebopeho (I-beams, angles)

3. Liphapang Tse ka Sehloohong Pakeng Tsa Litšepe Tse Fepisitsoeng le Tse Behiloeng

| Sebopeho | Tšepe e entsoeng | Tšepe e entsoeng |

|---|---|---|

| Tlhaloso | E petelitsoe tlas'a khatello e phahameng | E sebetsa ka mochini empa e sa etsoa |

| Sebopeho sa lijo-thollo | E hlophisitsoe ebile e hloekisitsoe | Uniform empa e nyane haholo |

| Matla | Matla a phahameng le ho tiea | Matla a itekanetseng |

| Lisebelisoa | Likarolo tsa khatello e phahameng, khatello e phahameng ea maikutlo | Lisebelisoa tse akaretsang tsa sebopeho |

| Tshebetso | Forging tobetsa, hamore, shoa | Ho thetheha, ho hula, ho ntša |

| Litšenyehelo | E phahameng ka lebaka la lisebelisoa le matla | Ea moruo haholoanyane ka bongata |

| Surface Finish | Sebaka se thata (se ka etsoa ka mochini) | Ka kakaretso boreleli holim'a metsi |

4. Maemo le Litifikeiti

Lihlahisoa tse Forged:

- ASTM A182 (Alloy e Forged or Rolled and Stainless Steel Pipe Flanges)

- ASTM B564 (Nickel Alloy Forgings)

- ASME B16.5 / B16.47 (Forged Flanges)

Lihlahisoa tse entsoeng:

- ASTM A403 (Li-Fittings tsa Pipe ea tšepe e sa hloekang ea Austenitic)

- ASTM A240 (Poleite ea tšepe e senyehileng e sentsoeng, Leqephe, le Strip)

- ASTM A554 (Tubing ea Mechanical e Welded Stainless Stainless)

5. Ke Efe eo U Lokelang ho e Khetha: E Fepiloe Kapa E Entsoe?

Khetho pakeng tsa tšepe e entsoeng le e entsoeng e itšetlehile haholo ka litlhoko tsa kopo:

Khetha tšepe e entsoeng ka tšepe ha:

- Karolo e tlas'a khatello e matla kapa khatello (mohlala, li-flanges tse nang le khatello e phahameng, li-shafts tse bohlokoa)

- Ho hlokahala matla a phahameng le ho hanyetsa mokhathala

- Botšepehi ba dimensional bo bohlokoa tlas'a mojaro

Khetha tšepe e betliloeng ha:

- Karolo ha e na ho ba le mojaro o feteletseng

- Machinability le weldability ke tsa bohlokoa

- Ho hlokahala tlhahiso e phahameng ka theko e tlaase

6. Likopo tsa Indasteri

| Indasteri | Lihlahisoa tsa Forged | Lihlahisoa tse entsoeng |

| Oli le Khase | Li-valve tsa khatello e phahameng, li-flanges | Lisebelisoa tsa lipeipi, li-elbows |

| Sepakapaka | Likarolo tsa enjene ea jet, li-disk tsa turbine | Liphanele tsa sebopeho, li-brackets |

| Tsa makoloi | Li-crankshafts, lithupa tse kopanyang | Liphanele tsa 'mele, li-tubing tsa exhaust |

| Moloko oa Matla | Li-rotor tsa turbine, mehele | Li-tubes tsa condenser, letlapa la tšepe |

| Kaho | Litholoana tse jarang moroalo | Mabala, litlaleho tsa sebopeho |

7. Metallurgical Insights: Ke Hobane'ng ha Forging e Etsa Metal e Matla haholoanyane

Forging e khutlisetsa phallo ea lijo-thollo ho latela sebōpeho sa karolo, ho tlosa li-discontinuities le meeli ea lijo-thollo e sebetsang e le lintlha tse fokolang. Ntlafatso ena ea lijo-thollo e etsa hore likarolo tse entsoeng ka maiketsetso li be matla haholo 'me li tšepahale haholoanyane libakeng tse sa khathaleng ke mokhathala.

Lisebelisoa tse entsoeng li boetse li rua molemo ho sebetsa ka mochine, empa mohaho o ka hare ha o ntlafatsoe ho feta likarolo tse entsoeng.

8. Lipotso ka Metal e entsoeng le e entsoeng

Na tšepe e ka etsoa le ho etsoa?

Ee. "Ho sebetsoa" ho hlalosa boemo bo akaretsang ba ho sebetsa ka polasetiki, 'me ho forging ke mofuta o mong oa ts'ebetso e entsoeng.

Na tšepe e entsoeng ka tšepe e tšoana le e entsoeng?

Che. Cast metal e entsoe ka ho tšela tšepe e qhibilihisitsoeng ka har'a hlobo, 'me e atisa ho ba le likarolo tse kholo tsa lijo-thollo le porosity e eketsehileng.

Ke hofe ho molemo bakeng sa ho hanyetsa kutu?

Ho hanyetsa kutu ho itšetlehile ka sebopeho sa thepa. Leha ho le joalo, lisebelisoa tse entsoeng li ka fana ka khanyetso e ntle libakeng tse ling ka lebaka la ho fokotseha ha porosity.

Na tšepe e entsoeng e matla ho feta tšepe e entsoeng ka tšepe?

Ka kakaretso ha ho joalo. Tšepe e entsoeng ka tšepe e matla ka lebaka la ho lumellana ha lijo-thollo hantle le mefokolo e fokolang ea ka hare.

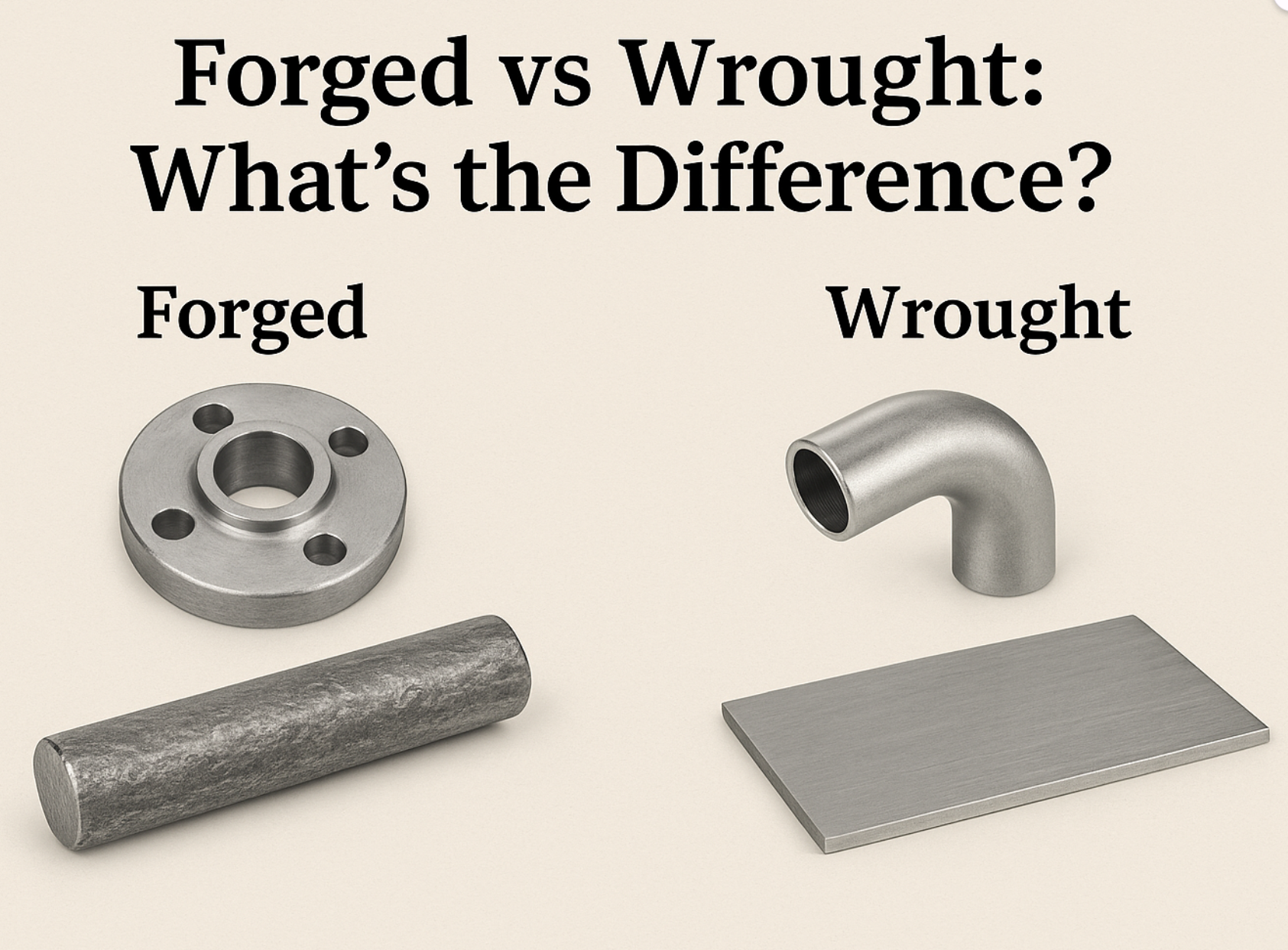

9. Papiso ea Pono: Lihlahisoa tsa Metal tse Forged vs Wrought

(Kenyelletsa setšoantšo sa papiso se bonts'ang flange e ferekaneng le molamu khahlano le setsoe le lakane)

10. Qetello: Tseba Tšepe ea Hao, Khetha ka Tšepo

Ho utloisisa phapang lipakeng tsa litšepe tse entsoeng le tse entsoeng ho bohlokoa haholo lits'ebetsong tsa boenjiniere le tsa indasteri. Likarolo tse entsoeng ka maiketsetso li fana ka matla a phahameng, ho hanyetsa mokhathala, le sebopeho sa lijo-thollo, se etsa hore e be tse loketseng likarolo tse phahameng tsa khatello ea maikutlo. Ka lehlakoreng le leng, likarolo tse sebetsang li fana ka ts'ebeliso e ntle ea litšenyehelo, ho ts'oana, le sebopeho se setle bakeng sa ts'ebeliso e akaretsang.

Ha u khetha lihlahisoa tsa tšepe bakeng sa morero oa hau, kamehla nahana ka:

- Tikoloho ya kopo

- Lintho tse hlokahalang tsa mechine

- Mekhoa ea indasteri

- Tekanyetso ea tlhahiso

Ho sa tsotellehe hore na u batla litšepe tsa tšepe tse sa hloekang kapa litšepe tsa setsoe, ho tseba hore na morao-rao—e entsoeng kapa e entsoeng—ho thusa ho etsa bonnete ba hore u khetha tšepe e nepahetseng, e sebetsang hantle, ka theko e nepahetseng.

Nako ea poso: Jul-22-2025