Thaum nws los txog rau kev tsim hlau, ob nqe lus feem ntau tshwm sim ib sab: forged thiab wrought. Txawm hais tias lawv yuav zoo sib xws thaum xub thawj siab ib muag, lawv sawv cev rau ob pawg ntawm kev ua hlau nrog cov yam ntxwv tshwj xeeb, kev ua tau zoo, thiab kev siv. Kev nkag siab txog qhov sib txawv ntawm cov hlau forged thiab wrought hlau yog qhov tseem ceeb rau cov engineers, manufacturers, thiab cov neeg yuav khoom thaum xaiv cov khoom siv rau lawv cov kev siv tshwj xeeb.

Hauv tsab xov xwm no, peb yuav tshawb nrhiav qhov sib txawv ntawm forged thiab wrought hlau nyob rau hauv cov ntsiab lus ntawm cov ntsiab lus, kev tsim khoom, cov khoom siv kho tshuab, cov qauv, cov khoom piv txwv, thiab lwm yam.

1. Forged txhais li cas hauv kev ua hlau?

Forging yog ib qho txheej txheem deformation uas suav nrog kev siv lub zog compressive rau hlau, feem ntau ntawm qhov kub thiab txias, los ua nws rau hauv daim ntawv xav tau. Forging yuav ua tau los ntawm hammering, nias, los yog dov cov hlau siv tuag.

Cov yam ntxwv tseem ceeb ntawm Forged Hlau:

- Refined grain qauv

- Siab zog thiab toughness

- Kev qaug zog zoo dua

- Tsawg cov voids sab hauv lossis suav nrog

Common Forged Khoom:

- Flanges

- Ncej

- Nplhaib

- Gears

- Cov khoom siv ntawm cov hlab ntsha siab

Hom Forging:

- Qhib-tuag forging: Zoo tagnrho rau cov khoom loj.

- Kaw-tuag (kev xav tuag) forging: Siv rau cov duab meej dua.

- Seamless dov nplhaib forging: Feem ntau siv hauv aerospace thiab lub zog tsim hluav taws xob.

2. Wrought Hlau yog dab tsi?

Lo lus "wrought" yog hais txog cov hlau uas tau ua haujlwm rau hauv nws daim ntawv kawg, feem ntau yog dov, kos duab, extruding, los yog forging. Lub tswv yim tseem ceeb yog cov hlau wrought tsis yog cam khwb cia, txhais tau tias lawv tsis tau nchuav los ntawm cov hlau molten rau hauv pwm.

Cov yam ntxwv ntawm Wrought Hlau:

- Ductile thiab malleable

- Uniform grain qauv

- Yooj yim rau tshuab thiab vuam

- Zoo nto tiav

Common Wrought Khoom:

- Tube thiab tubing

- Lub luj tshib thiab tees

- Phaj thiab ntawv hlau

- Hlau thiab rods

- Cov qauv duab (I-beams, ces kaum)

3. Qhov txawv tseem ceeb ntawm Forged thiab Wrought Hlau

| Feature | Forged Hlau | Wrought Hlau |

|---|---|---|

| Txhais | Compressed nyob rau hauv siab | Mechanically ua hauj lwm tab sis tsis cam khwb cia |

| Grain Structure | Aligned thiab refined | Uniform tab sis tsawg ntom |

| Lub zog | Siab zog thiab toughness | Lub zog nruab nrab |

| Daim ntawv thov | High-pressure, high-stress qhov chaw | General structural applications |

| Txheej txheem | Forging xovxwm, rauj, tuag | Rolling, kos duab, extruding |

| Nqi | Siab dua vim cov cuab yeej thiab lub zog | Kev lag luam ntau dua hauv cov khoom loj |

| Nto tiav | Rougher nto (yuav tsum machined) | Feem ntau smoother nto |

4. Cov qauv thiab ntawv pov thawj

Cov khoom Forged:

- ASTM A182 (Forged lossis Rolled Alloy thiab Stainless Hlau Yeeb Flanges)

- ASTM B564 (Nickel Alloy Forgings)

- ASME B16.5 / B16.47 (Forged Flanges)

Wrought Khoom:

- ASTM A403 (Wrought Austenitic Stainless Hlau Yeeb Nkab Fittings)

- ASTM A240 (Wrought Stainless Hlau Phaj, Ntawv, thiab Sawb)

- ASTM A554 (Welded Stainless hlau Mechanical Tubing)

5. Koj Yuav Xaiv Ib Tug: Forged lossis Wrought?

Qhov kev xaiv ntawm forged thiab wrought hlau nyob ntawm qhov xav tau ntawm daim ntawv thov:

Xaiv cov hlau forged thaum:

- Ib feem yog muaj kev ntxhov siab lossis siab (piv txwv li, siab flanges, shafts tseem ceeb)

- Superior zog thiab qaug zog kuj yuav tsum tau

- Dimensional kev ncaj ncees yog qhov tseem ceeb nyob rau hauv load

Xaiv cov hlau wrought thaum:

- Cov tivthaiv tsis muaj kev thauj khoom hnyav

- Machinability thiab weldability yog qhov tseem ceeb

- Cov khoom ntim siab yog xav tau ntawm tus nqi qis

6. Cov ntawv thov kev lag luam

| Kev lag luam | Cov khoom Forged | Wrought Khoom |

| Roj & Roj | High-pressure li qub, flanges | Cov yeeb nkab fittings, luj tshib |

| Aerospace | Dav hlau cav qhov chaw, turbine disks | Cov qauv vaj huam sib luag, brackets |

| Automotive | Crankshafts, txuas rods | Lub cev panels, tso pa tawm |

| Lub zog tiam | Turbine rotors, rings | Condenser raj, ntawv hlau |

| Kev tsim kho | Load-bearing pob qij txha | Beams, structural profiles |

7. Metallurgical Insights: Vim li cas Forging ua kom muaj zog hlau

Forging realigns cov nplej ntws los ua raws li cov duab ntawm ib feem, tshem tawm kev tsis sib xws thiab cov ciam teb uas ua raws li cov ntsiab lus tsis muaj zog. Qhov no grain refinement ua forged Cheebtsam ho muaj zog thiab ntau txhim khu kev qha nyob rau hauv qaug zog-rhiab qhov chaw.

Wrought cov ntaub ntawv kuj tau txais txiaj ntsig los ntawm kev siv tshuab ua haujlwm, tab sis cov qauv sab hauv tsis zoo dua li ntawm qhov forged.

8. FAQs Txog Forged thiab Wrought Hlau

Cov hlau puas tuaj yeem yog forged thiab wrought?

Yog lawm. "Wrought" piav qhia txog lub xeev ntawm kev ua haujlwm ntawm plastically, thiab forging yog ib hom txheej txheem wrought.

Puas yog cam khwb cia hlau zoo ib yam li wrought?

Tsis yog. Cam khwb cia hlau yog tsim los ntawm pouring hlau molten rau hauv pwm, thiab nyhav kom muaj cov khoom loj dua thiab porosity ntau dua.

Dab tsi yog qhov zoo dua rau kev tiv thaiv corrosion?

Corrosion kuj nyob ntawm cov khoom muaj pes tsawg leeg. Txawm li cas los xij, cov ntaub ntawv forged tuaj yeem muab kev tiv thaiv zoo dua hauv qee qhov chaw vim tias txo qhov porosity.

Yog wrought steel muaj zog dua forged steel?

Feem ntau tsis muaj. Forged steel muaj zog dua vim yog cov nplej zoo sib xws thiab tsawg dua qhov tsis xws luag.

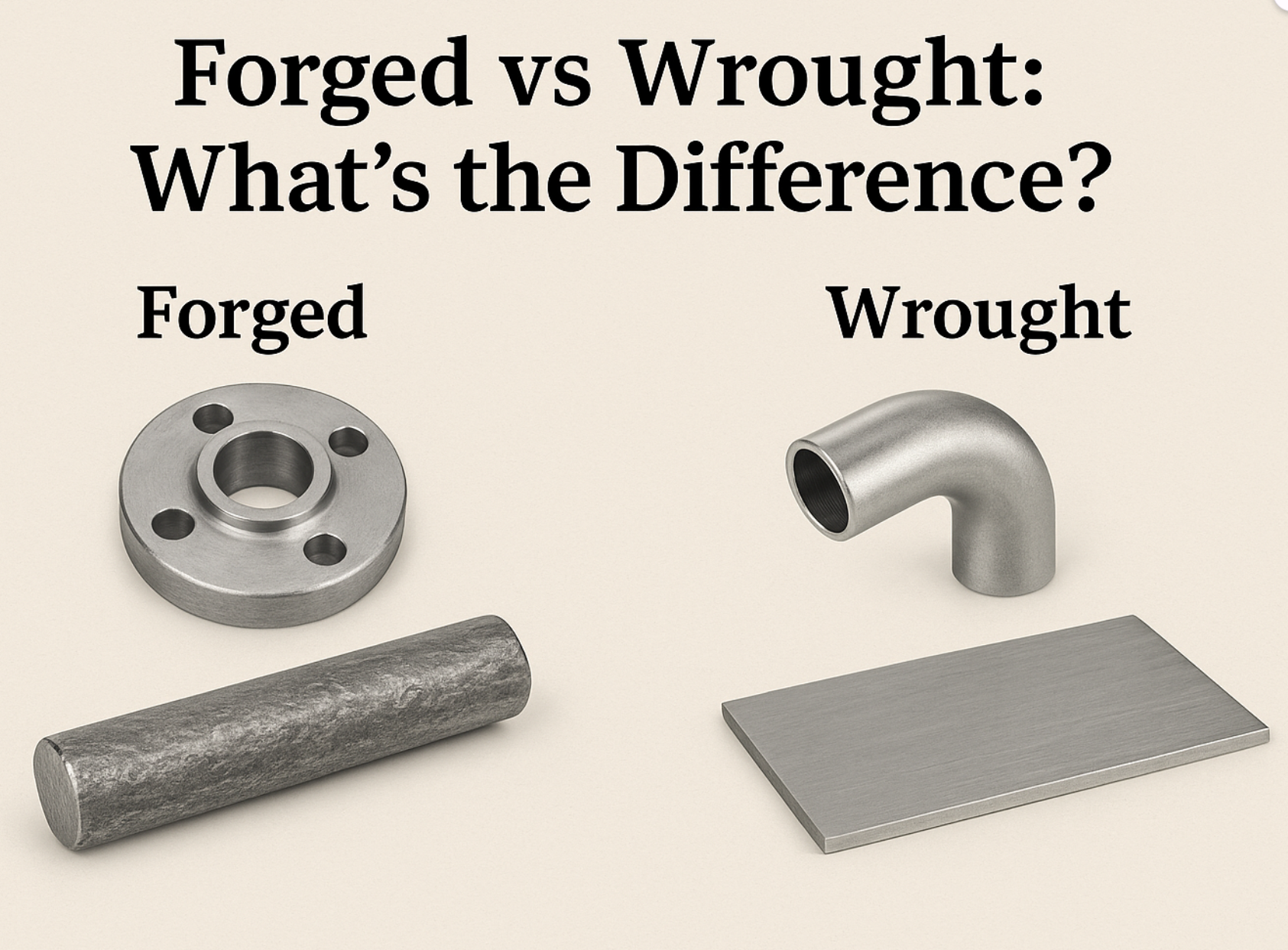

9. Pom kev sib piv: Forged vs Wrought hlau khoom

(Suav nrog cov duab sib piv uas qhia forged flange thiab pas nrig vs wrought luj tshib thiab daim ntawv)

10. Xaus: Paub koj cov hlau, xaiv nrog kev ntseeg siab

Nkag siab qhov sib txawv ntawm cov hlau forged thiab wrought hlau yog qhov tseem ceeb hauv engineering thiab kev siv tshuab. Forged Cheebtsam muab lub zog zoo dua, qaug zog ua haujlwm, thiab cov qauv nplej, ua rau lawv zoo tagnrho rau qhov chaw muaj kev ntxhov siab. Wrought Cheebtsam, ntawm qhov tod tes, muab nqi-efficiency, uniformity, thiab zoo heev formability rau kev siv.

Thaum xaiv cov khoom hlau rau koj qhov project, nco ntsoov xav txog:

- Kev thov ib puag ncig

- Yuav tsum muaj cov khoom siv kho tshuab

- Cov qauv kev lag luam

- Kev siv nyiaj txiag

Txawm hais tias koj tab tom nrhiav stainless hlau flanges los yog lub luj tshib fittings, paub txog kev tsim keeb kwm yav dhau - forged los yog wrought - pab kom koj xaiv cov hlau zoo, nrog rau kev ua tau zoo, ntawm tus nqi raug.

Post lub sij hawm: Lub Xya hli ntuj-22-2025