Tubus chalybis inoxidabilis sine sutura, magni diametri

Descriptio Brevis:

| Specificationes tubi chalybis inoxidabilis sine suturis: |

| 1. Norma: | ASTM A312 A213 A269 A511 A789 A790, JIS3463, JIS3459,DIN2462,DIN17456 |

| 2. Gradus: | 304, 310S, 316, 316L, 321, 321H, 317L, 904L, 2205, et cetera. |

| 3. Spatium OD: | 200-800mm |

| 4. Intervallum Crassitudinis Muri: | SCH-5S, SCH-10S, SCH-20S, SCH-40 |

| 5. Superficies Superficialis: | Conditus, Splendens, Sabulo Iactus, Politio, etc. |

| 6. Technicae: | Calido laminatum, frigido tractum |

| 7. Experimentum: | Analysis Chemica, Examen Hydrostaticum vel Nondestructivum Electricum, Examen Corrosionis Intergranularis, Examen Flaringis,Examen ApplanationisExamen flangis, Examen magnitudinis grani, Examen aeris sub aqua, Examen ultrasonicum, Examen currentis turbinalis |

| 8. Involucrum: | Fasciculus. Capsa lignea compacta. Opercula extrema in utroque extremo. |

| Compositio Chemica: |

| Gradus | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 201 | .15 Maximus | 5.5 - 7.5 | 1.00 Maximus | .060 Maximus | .030 Maximus | XVI - XVIII | 3.5-5.5 | .25 Maximus | |

| 202 | .15 Maximus | 5.5 - 7.5 | 1.00 Maximus | .060 Maximus | .030 Maximus | XVI - XVIII | 3.5-5.5 | .25 Maximus | |

| 301 | 0.15 maximum | 2.00 maximum | 1.00 maximum | 0.045 maximum | 0.030 maximum | XVI-XVIII | VI–VIII | 0.10 | |

| 302 | 0.15 | 2.00 maximum | 0.75 | 0.05 | 0.03 | XVII–XIX | - | 8–10 | 0.10 |

| 302B | 0.15 | 2.00 maximum | 2.0–3.0 | 0.05 | 0.03 | XVII–XIX | - | 8–10 | - |

| 304 | 0.08 | 2.00 maximum | 0.75 | 0.05 | 0.03 | XVIII-XX | - | 8-10.5 | 0.10 |

| 304L | 0.03 | 2.00 maximum | 0.75 | 0.05 | 0.03 | XVIII-XX | VI–XII | 0.10 | |

| 304H | 0.04-0.01 | 2.00 maximum | 0.75 | 0.05 | 0.03 | XVIII-XX | 8-10.5 | - | |

| CCCX | 0.25 | 2.00 maximum | 1.50 | 0.05 | 0.03 | XXIV-XXVI | - | XIX-XXII | - |

| 310S | 0.08 | 2.00 maximum | 1.50 | 0.05 | 0.03 | XXIV-XXVI | - | XIX-XXII | - |

| CCCXVI | 0.08 | 2.00 maximum | 0.75 | 0.05 | 0.03 | XVI-XV | 2–3 | 10–14 | 0.10 |

| 316L | 0.03 | 2.00 maximum | 0.75 | 0.05 | 0.03 | XVI-XVIII | 2–3 | 10–14 | 0.10 |

| 321 | 0.08 | 2.00 maximum | 0.75 | 0.05 | 0.03 | XVII–XIX | 9–12 | 0.10 | |

| 410 | .080-.150 | 1.00 maximum | 1.00 Maximus | 0.04 | 0.030 maximum | 11.5-13.5 | 0.75 maximum |

| Tubus Chalybis Inoxidabilis Magni Diametri JIS G3468, CNS 13517 Specificatio: |

| Nominalis | Nominalis | Extra | SCH-5S | SCH-10S | SCH-20S | SCH-40 |

| Diameter | Diameter | Diameter (mm) | Crassitudo parietis nominalis (mm) | Crassitudo parietis nominalis (mm) | Crassitudo parietis nominalis (mm) | Crassitudo parietis nominalis (mm) |

| A | B | |||||

| CL | 6 | 165.2 | 2.8 | 3.4 | 5 | 7.1 |

| ducenti | 8 | 216.3 | 2.8 | 4 | 6.5 | 8.2 |

| 250 | 10 | 267.4 | 3.4 | 4 | 6.5 | 9.3 |

| trecenti | 12 | 318.5 | 4 | 4.5 | 6.5 | 10.3 |

| 350 | 14 | 355.6 | 4 | 5 | 8 | 11.1 |

| quadringenti | 16 | 406.4 | 4.5 | 5 | 8 | 12.7 |

| 450 | 18 | 457.2 | 4.5 | 5 | 8 | 14.3 |

| quingenti | 20 | 508 | 5 | 5.5 | 9.5 | 15.1 |

| 550 | 22 | 558.8 | 5 | 5.5 | 9.5 | 15.9 |

| DC | 24 | 609.6 | 5.5 | 6.5 | 9.5 | 17.5 |

| DCCL | 26 | 660.4 | 5.5 | 8 | 12.7 | - |

| DCC | 28 | 711.2 | 5.5 | 8 | 12.7 | - |

| DCCCL | 30 | DCCCLXII | 6.5 | 8 | 12.7 | - |

| DCCC | 32 | 812.8 | - | 8 | 12.7 | - |

| DCCCL | 34 | 863.6 | - | 8 | 12.7 | - |

| 900 | 36 | 914.4 | - | 8 | 12.7 | - |

| mille | 40 | 1016 | - | 9.5 | 14.3 | - |

| 1050 | 42 | 1066.8 | Cum dimensiones aliae quam eas quae in tabula supradicta datae sunt requiruntur, dimensiones prout inter emptorem et fabricatorem (sakysteel) conventum est determinandae sunt. | |||

| | | | | | | ||||

| 1650 | 66 | 1676.4 | ||||

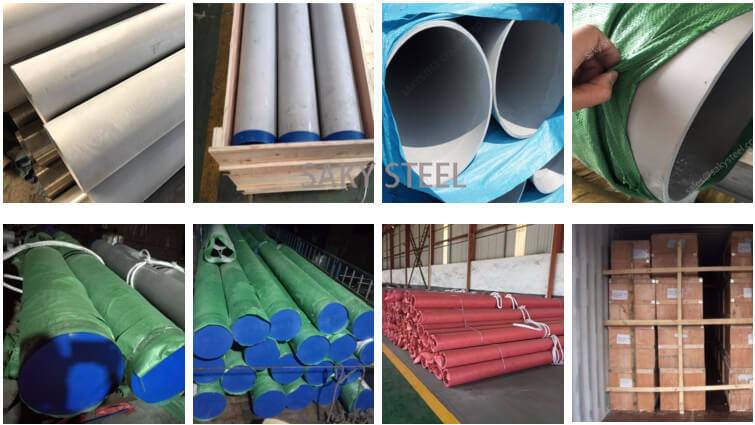

| Involucrum et Transportatio: |

Informationes de involucris tubi sine sutura chalybis inoxidabilis:

Involucrum PVC, involucrum cartonis, vel ut emptor postulat capsa lignea.

Involucrum interius: 1 saccus plasticus (polythenus) / pars, et 500kg in uno fasciculo convasantur.

Involucrum externum: charta kraft, capsae ligneae, vel secundum petitiones emptorum.

Tubi chalybis inoxidabilis magni diametri tuto, celeriter et sine damno ad destinationem suam in quavis parte mundi pervenire debent.

Involucrum etiam pars essentialis curationis qualitatis est.

Applicationes:

Sakysteel praecipue adhibetur ut fistula perforans pro geologia petrolei, fistula fissurarum pro industria petrochemica, fistula caldariorum, fistula portantis, et fistula structuralis altae praecisionis pro autocinetis, tractricibus et aviatione.