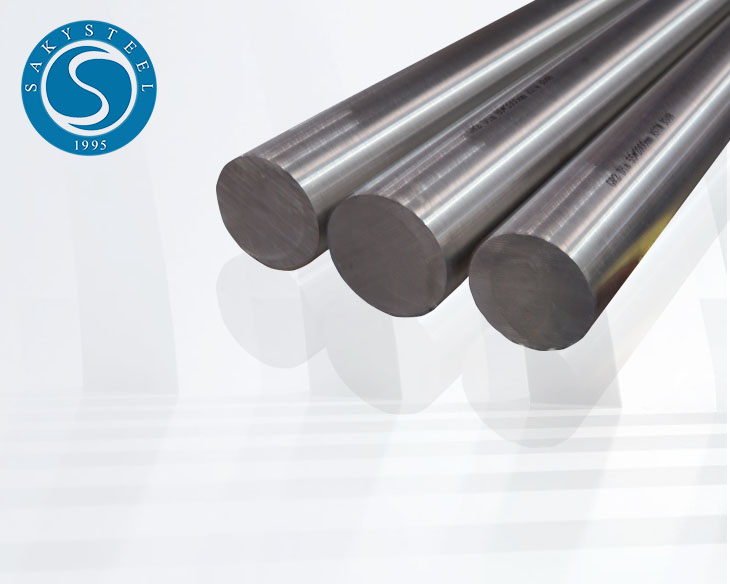

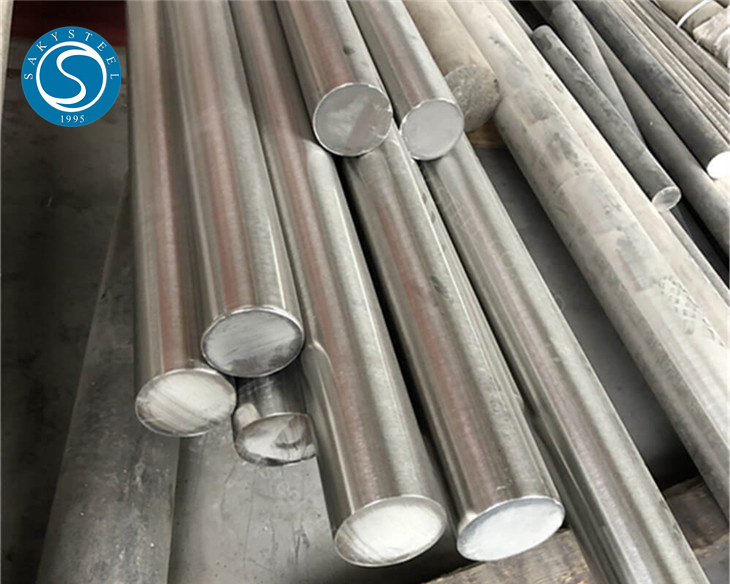

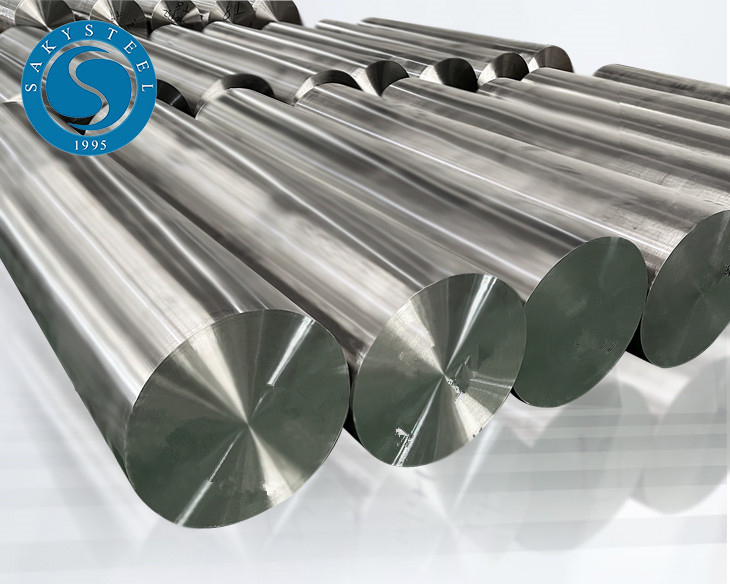

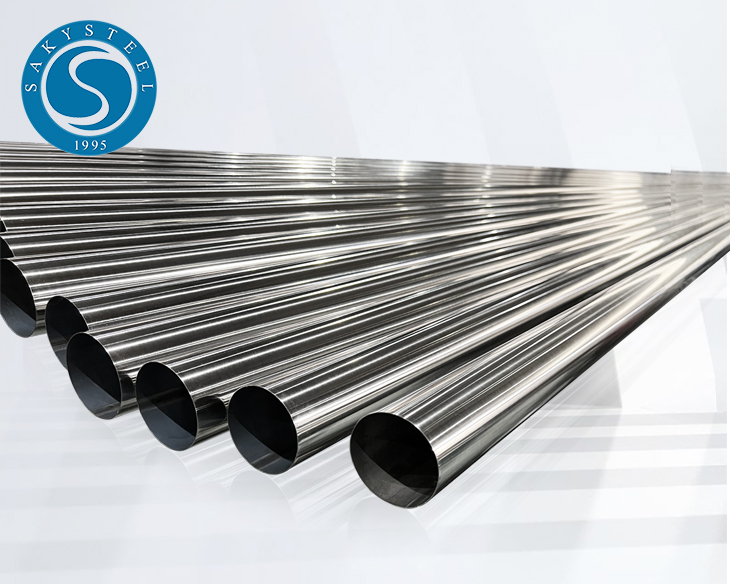

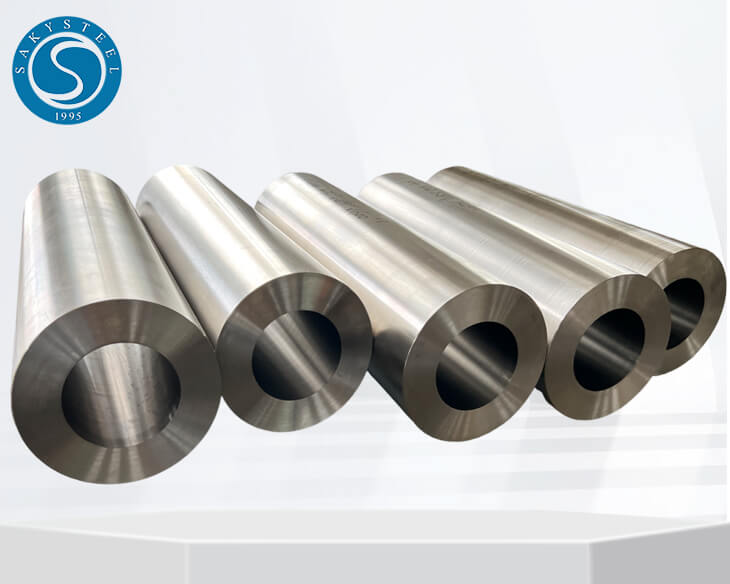

High-Quality 25mm Stainless Steel Bar for Durable Construction Projects

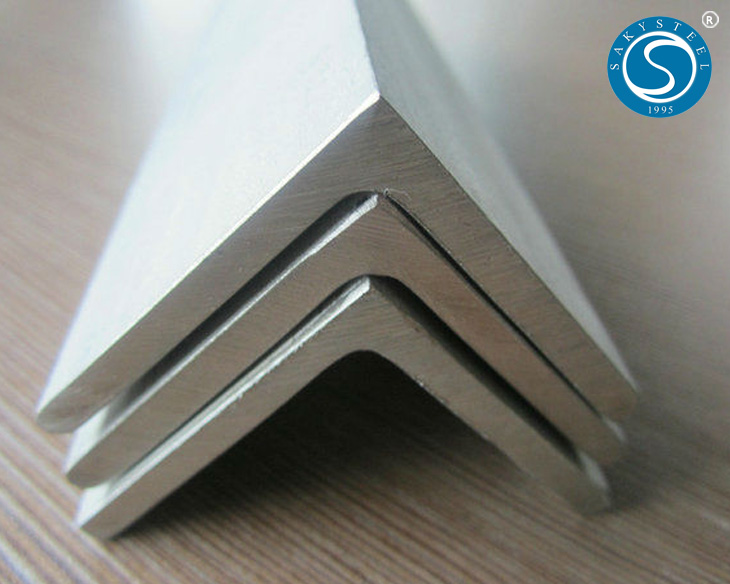

As a buyer eager to find reliable materials, I understand how crucial it is to choose the right components for projects. The 25mm Stainless Steel Bar stands out for its durability and versatility, perfect for various applications such as construction, manufacturing, and even marine environments. I value the corrosion resistance that stainless steel offers, which means my products can withstand the test of time. Given its strength and reliability, it's no wonder this bar is popular among B2B purchasers like myself. With options available in different finishes and lengths, I can easily find the right specification to meet my project needs. Plus, I appreciate suppliers that provide fast shipping and excellent customer service so my orders arrive on time. If you’re in the market for dependable materials, that 25mm Stainless Steel Bar could be just what you need to ensure quality in your next project.

25mm Stainless Steel Bar Winning in 2025 From Concept to Delivery

In the rapidly evolving landscape of manufacturing and supply chains, the demand for quality materials is at an all-time high. The 25mm stainless steel bar is poised to be a game-changer in 2025, with its versatility and durability making it an ideal choice for various applications across industries. From construction to automotive and beyond, this robust material is designed to meet the rigorous demands of global procurement needs. With a focus on innovative design and sustainable practices, suppliers are well-equipped to transition from concept to delivery effectively, ensuring that businesses receive the materials they need, when they need them. As we prepare for the future, it is essential for procurement professionals to understand the implications of sourcing high-quality stainless steel bars. With advancements in production techniques, including refined alloy compositions and state-of-the-art manufacturing processes, these bars not only offer enhanced strength and corrosion resistance but also contribute to sustainability goals. Buyers can expect efficient lead times and reliable delivery, bridging the gap between expectation and reality in modern supply chains. By prioritizing partnerships with forward-thinking manufacturers, businesses can secure a competitive edge in their respective markets. Ultimately, the shift towards high-grade materials like the 25mm stainless steel bar reflects a larger trend in global manufacturing. It emphasizes the need for suppliers who can deliver not just on quality but also on innovation, transparency, and sustainability. As we look to 2025, companies that align their procurement strategies with these values will be well-positioned to thrive in a dynamic marketplace, unlocking new opportunities and fostering long-term success.

25mm Stainless Steel Bar Winning in 2025 From Concept to Delivery

| Feature | Description | Material Type | Applications | Expected Lifespan |

|---|---|---|---|---|

| Corrosion Resistance | Excellent resistance to corrosion due to the high chromium content. | Stainless Steel 304 | Food Processing, Chemical Plants | 15-20 years |

| Durability | Resistant to impact and wear. | Stainless Steel 316 | Marine Applications, Medical Equipment | 20-25 years |

| Versatility | Can be easily shaped and welded. | Stainless Steel 430 | Automotive, Construction | 10-15 years |

| Aesthetic Appeal | Provides a modern and clean look, often used for decorative purposes. | Polished Stainless Steel | Architectural Design, Furniture | Indefinite with proper care |

| Recyclability | Fully recyclable, making it a sustainable choice. | Alloy-based Stainless Steel | Infrastructure, Renewable Energy | Recyclable indefinitely |

Related Products